Flyash excitant and production process thereof

A technology of fly ash and activator, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of hindering promotion, tight supply and high production cost

Inactive Publication Date: 2006-10-11

葫芦岛市辽西混凝土外加剂有限公司

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although this kind of activator can effectively stimulate the potential activity of fly ash and increase the amount of fly ash in concrete and its products, however, since the basic composition of this activator is mostly industrial raw materials, the supply of these raw materials is increasingly tight , leading to higher production costs, hindering widespread promotion

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0076]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

Description

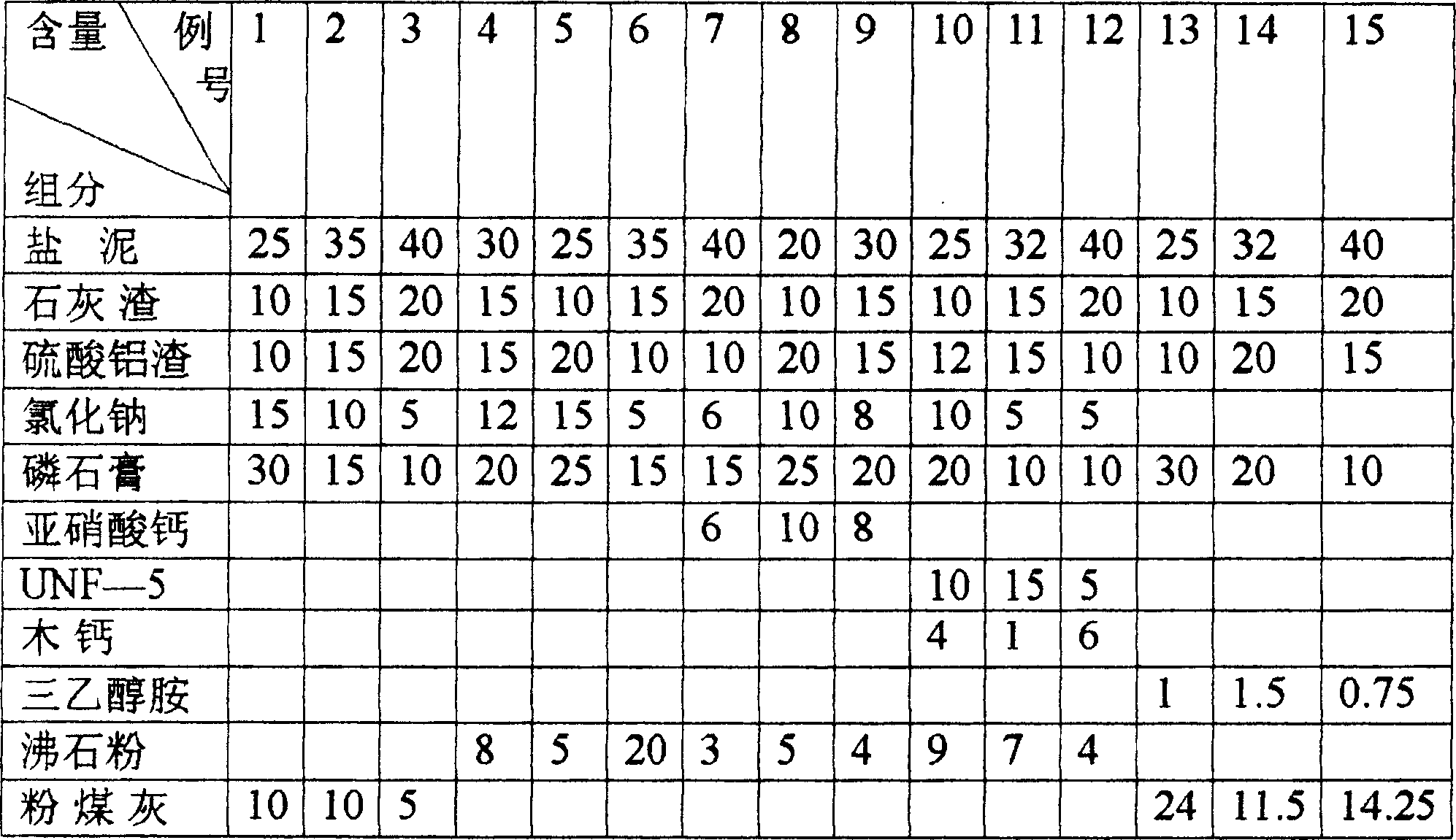

technical field [0001] The invention belongs to the field of building materials such as cement and concrete, and in particular relates to a concrete admixture and a cement additive for stimulating the chemical activity of fly ash and increasing its content in concrete and cement. Background technique [0002] At present, there are many research results on the comprehensive utilization of industrial waste fly ash, most of which focus on the core issue of how to improve the activity of fly ash. The specific measures include mechanical activation, physical activation and chemical activation. The existing fly ash activator, the patent No. is ZL03133657.4, is composed of sodium sulfate, calcium chloride, sodium chloride, superplasticizer, calcium lignosulfonate and phosphogypsum. Although this kind of activator can effectively stimulate the potential activity of fly ash and increase the amount of fly ash in concrete and its products, however, since the basic composition of this a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B18/08C04B22/14C04B22/12

CPCY02W30/91

Inventor 鞠秉秀詹学斌詹乐

Owner 葫芦岛市辽西混凝土外加剂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com