A Mo-V-Cr intermediate alloy and process for preparing same

An intermediate alloy, molybdenum-vanadium technology, applied in the field of molybdenum-vanadium-chromium master alloy and its preparation, can solve the problems of high cost, narrow adaptability, inability to meet diversification and the like, achieves low cost, low production cost, easy storage and transportation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The method of smelting by ignition outside the furnace is carried out according to the conventional steps, the raw materials are dried, the furnace is built, the ingredients are prepared according to the weight percentage, the materials are evenly mixed, the furnace is loaded, smelted, cooled, the furnace is started, weighing, finishing, crushing, magnetic Selection, sampling analysis, packaging.

[0017] Concrete preparation process is as follows:

[0018] 1. Drying of raw materials: Dry raw materials, masonry slag, and batching slag in a drying room at a temperature of 75°C (75±5°C) for no less than 24 hours (24 to 72 hours);

[0019] 2. Weighing raw materials: Calcium fluoride is used as a slagging agent during batching (the addition is 1.5-13.5% of the total amount of raw materials).

[0020] V 2 o 5 MoO 2 CrO 3 Al CaF 2

[0021] 1kg 0.339kg 0.9kg 1.07kg 0.1kg

[0022] 3. Mixing: put the material into the V-shaped mixer, mix evenly, and the nu...

Embodiment 2~4

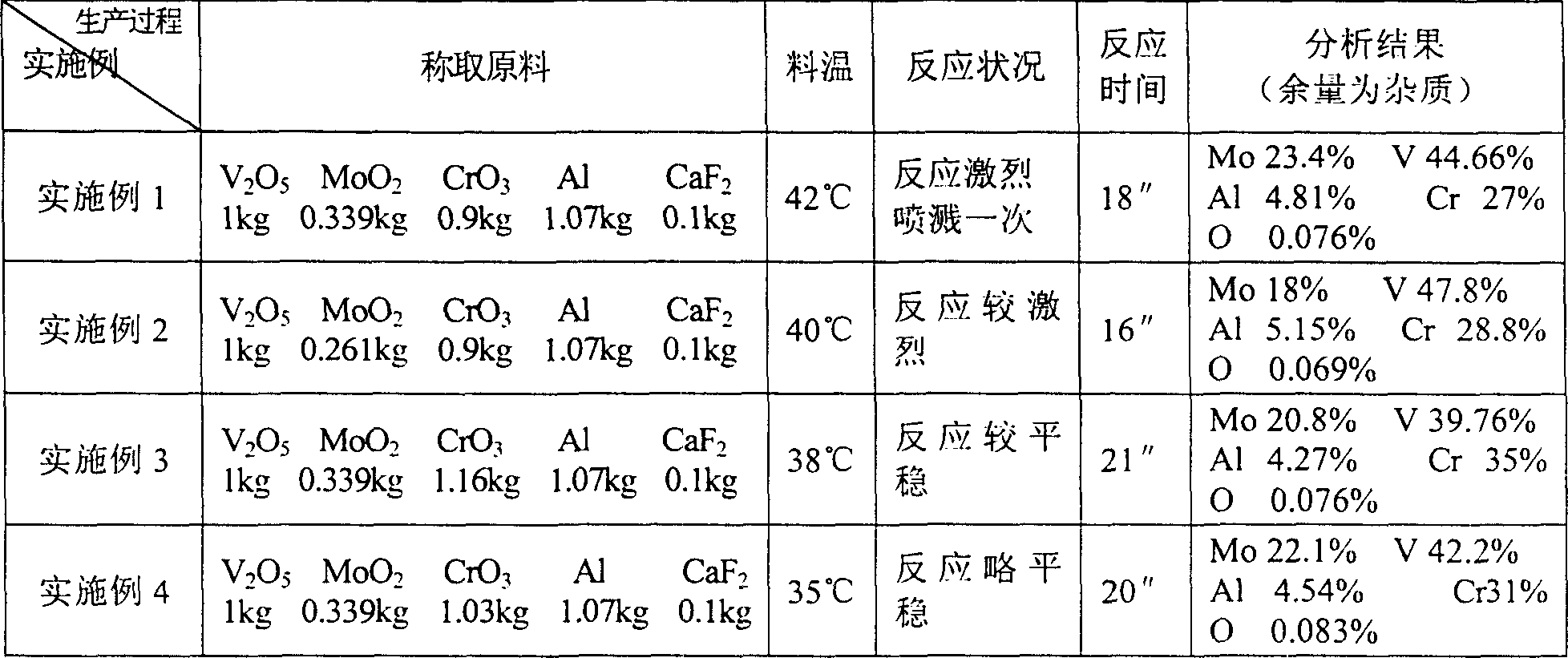

[0034] Embodiment 2~4. Operate by the method of embodiment 1, see table 1 with embodiment 1 difference.

[0035] Table 1. Molybdenum vanadium chromium alloy reaction system

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com