Ship pipe line sleeve type electric coupling insulation method

A technology for pipelines and ships, applied in the field of galvanic couple insulation of ship pipelines, can solve the problems of increased cost, inconvenient manufacturing and assembly, etc., and achieves the effects of easy replacement, simple and easy assembly, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

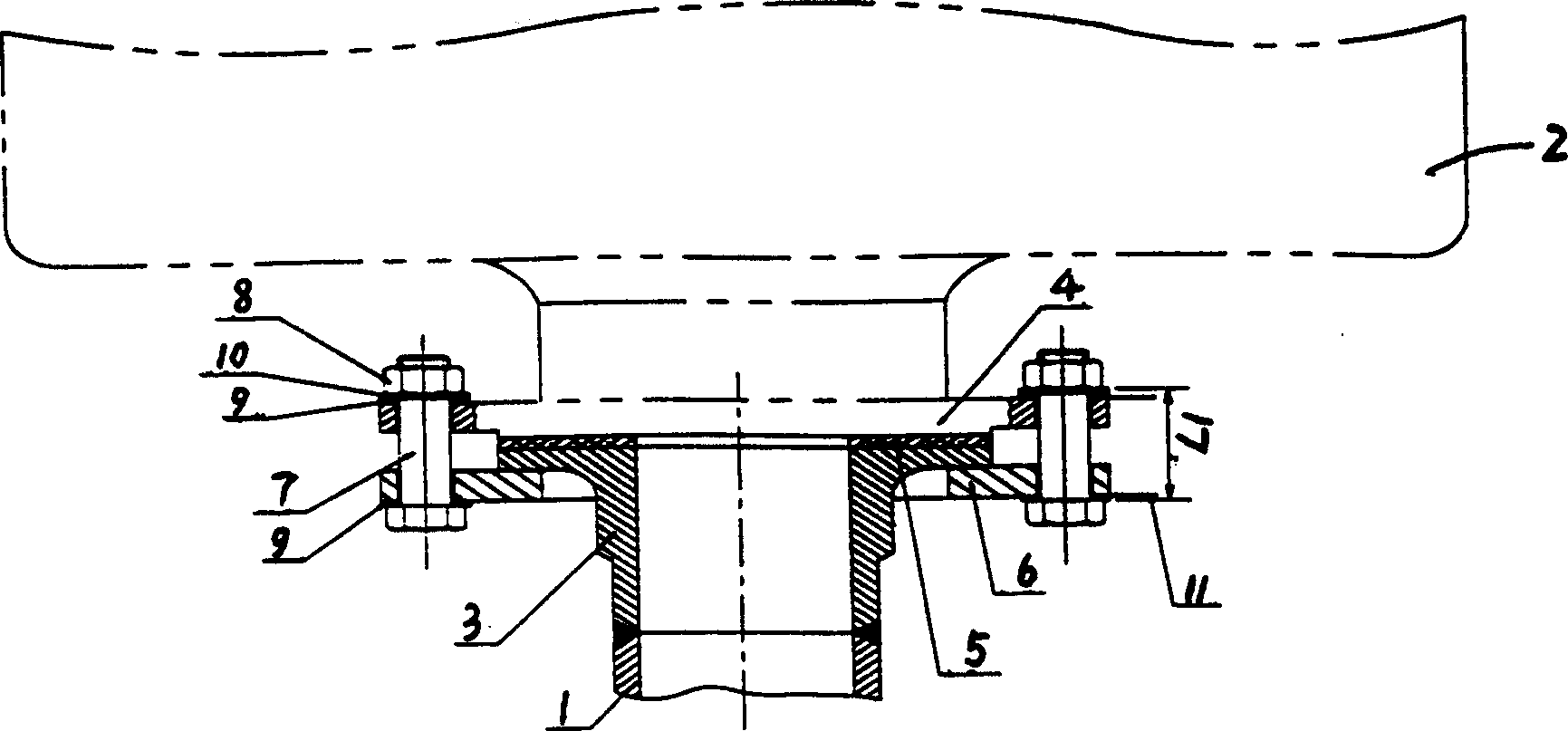

[0027] The ship pipeline casing type galvanic couple insulation method of the present invention is used for the connection of the alloy pipe in the ship pipeline and the piping accessories, such as figure 2 shown, including the following steps:

[0028] ①. Select the corresponding heat shrinkable sleeve specification according to the specification of the connecting bolt 7;

[0029] ②. According to the connection state of the connecting bolt 7, in order to achieve the galvanic insulation between the alloy pipe 1 and the piping accessory 2 (in this embodiment, it is necessary to ensure the insulation between the connecting bolt 7 and the alloy pipe 1 and the piping accessory 2), determine The length L1 of the heat-shrinkable sleeve that needs to be coated on the connecting bolt 7, and cut off the heat-shrinkable sleeve according to the length, and put it on the connecting bolt 7;

[0030] ③. Heat the heat-shrinkable sleeve with a cassette heating gun so that it is tightly wrap...

Embodiment 2

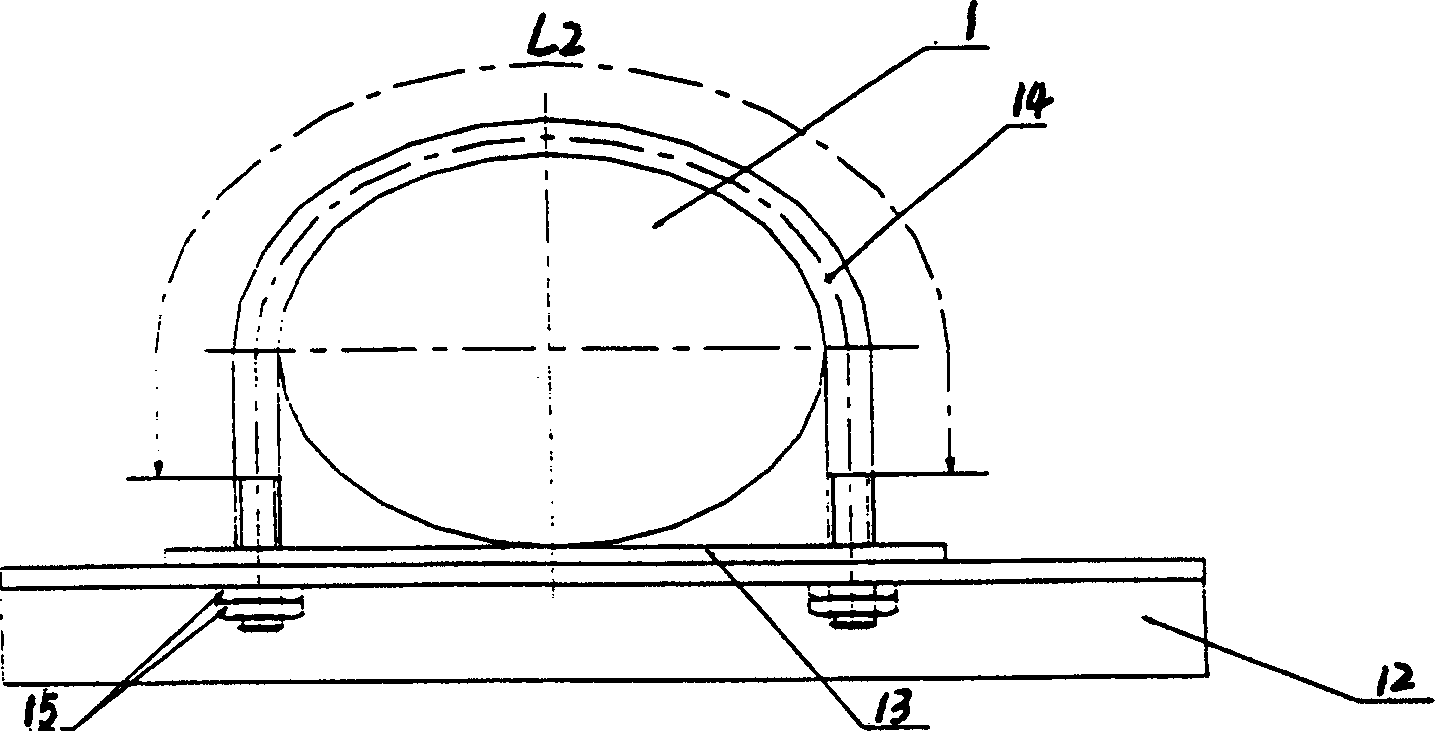

[0033] The ship pipeline casing type galvanic couple insulation method of the present invention is used for the connection between the alloy pipe and the support in the ship pipeline, such as image 3 shown, including the following steps:

[0034] ①. Select the corresponding heat shrinkable sleeve specifications according to the specifications of the U-bolt 14;

[0035] ②. According to the connection state of the U-shaped bolt 14, in order to achieve the galvanic insulation between the alloy pipe 1 and the support 12 (in this embodiment, it is necessary to ensure the insulation between the U-shaped bolt 14 and the alloy pipe 1), determine that the U-shaped bolt 14 is The length L2 of the heat-shrinkable sleeve needs to be coated, and the heat-shrinkable sleeve is cut according to this length, and put on the U-shaped bolt 14;

[0036] ③. Heat the heat-shrinkable sleeve with a cassette heating gun so that it is tightly wrapped on the U-shaped bolt 14;

[0037] ④. According to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com