A superluminescent light-emitting diode and its manufacturing method

A technology of superluminescence and manufacturing method, applied in the field of superluminescence light emitting diode and its manufacture, can solve the problems of high difficulty of polarization of light source of superluminescence light source and quantum well process control, and achieves reduction of current leakage, reduction of reflection, reduction of The effect of polarization extinction ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

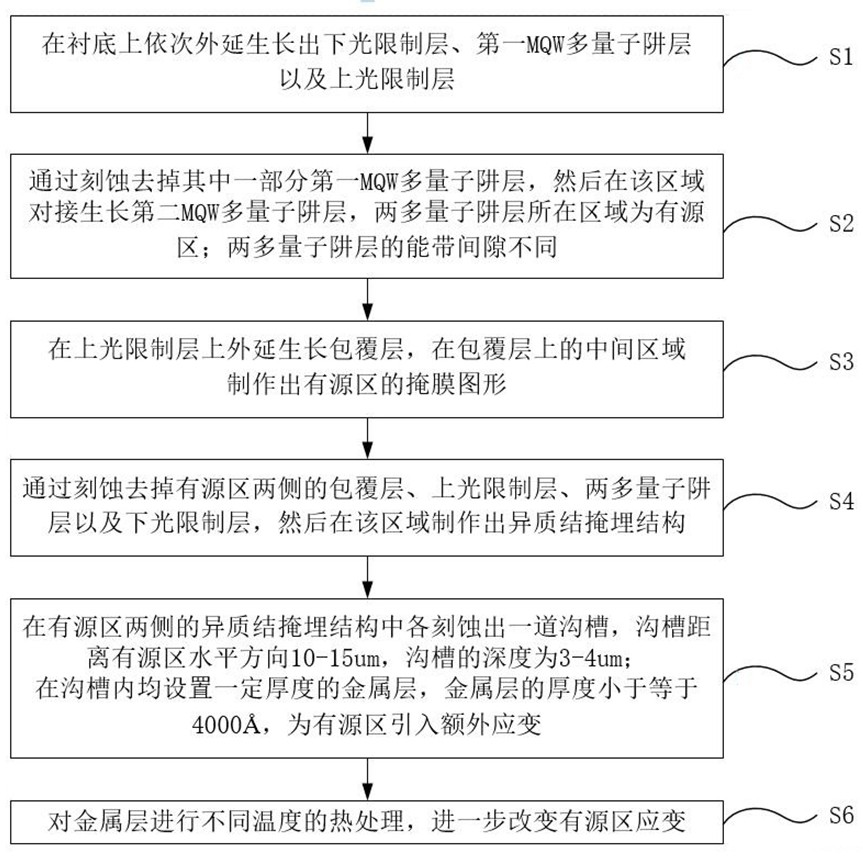

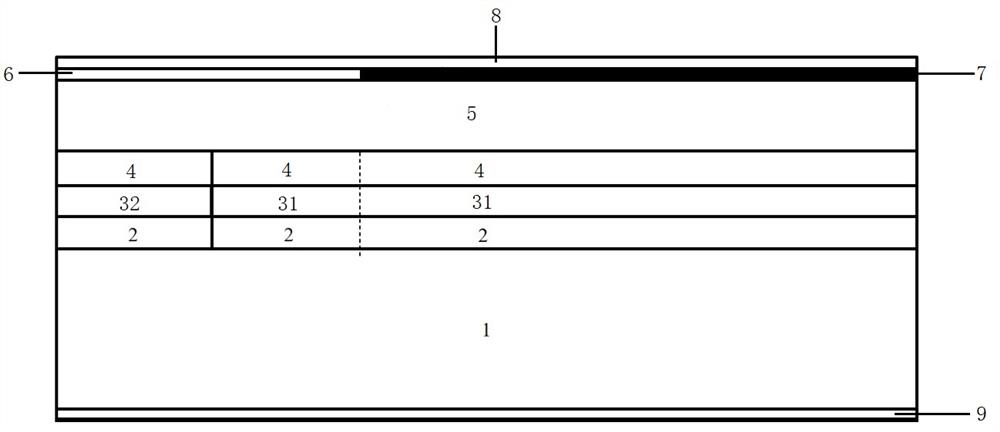

[0028] The present invention will be further described below in conjunction with accompanying drawing:

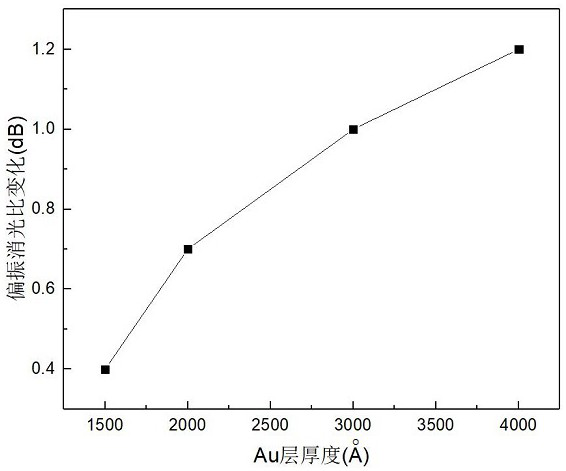

[0029] The present invention grows two kinds of MQW multi-quantum wells with different energy band gaps as the active layer by adopting the method of butt-butt growth, which can well control the quality of epitaxial growth, and will not be affected by the lattice constant between the quantum wells in the active layer. The difference introduces additional strain and affects the polarization extinction ratio and the reliability of the diode; by setting the heterojunction buried structure on both sides of the active region, in addition to confining the optical field in the buried active region, it can also grow reverse P The / N junction reduces current leakage; and by setting metal layers in the trenches on both sides of the active region, additional strain is introduced to the active region, thereby adjusting the stress distribution in the active region to achieve TE / TM mode m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com