Continuous preparation method of high-strength high-modulus single-orientation predipping band of polyethylene fiber

A polyethylene fiber, high-strength and high-modulus technology, used in protective equipment, offensive equipment, personnel protection equipment, etc., can solve problems such as separation difficulties and production difficulties of standard products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

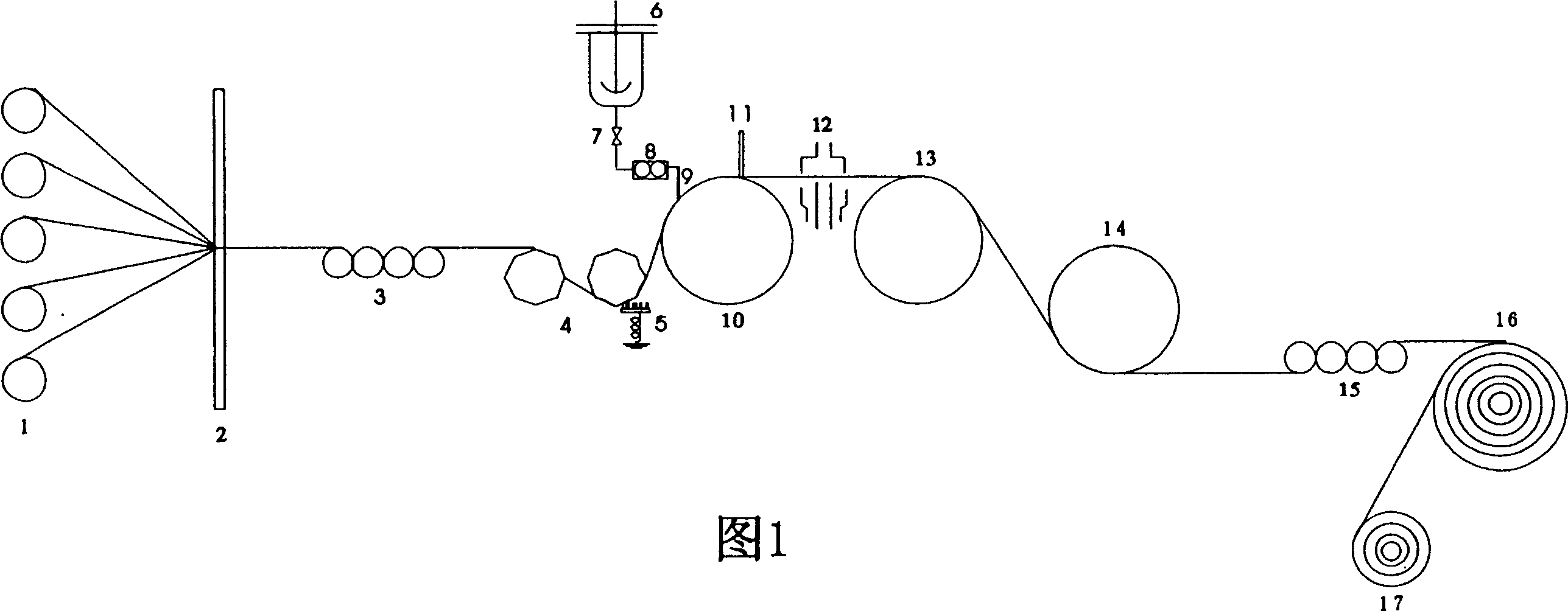

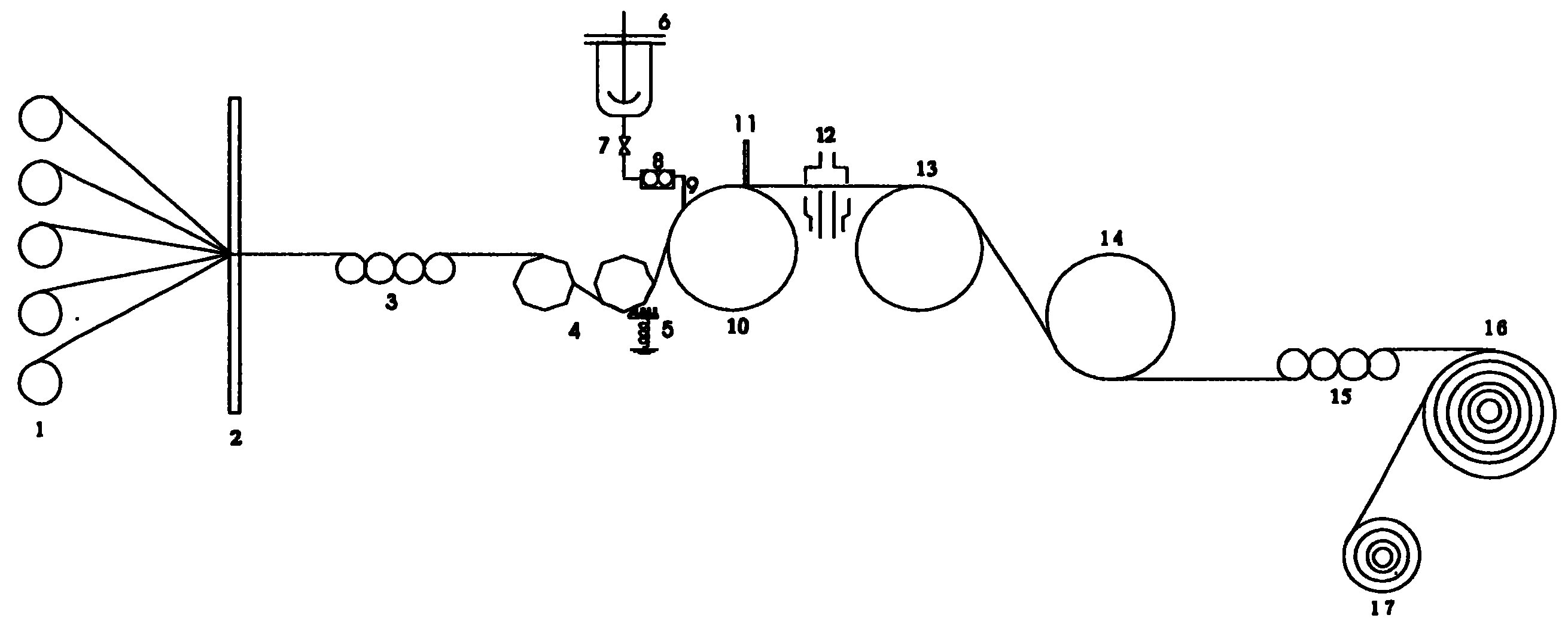

[0032] Use ZTX99 400f high-strength high-modulus polyethylene fiber (1) (strength ≥ 35g / d, fineness 2.0-2.5d), pass through 3 reed / cm reed (2) and tension frame (3), and then rub with polygonal prism roller (4) Friction, the friction roller (4) can be made of chromium oxide, magnesium oxide or aluminum oxide material, or a layer of chromium oxide, magnesium oxide or aluminum oxide material can be coated on the surface of the roller made of other materials. The surface layer of the friction roller (4) used in the embodiment is coated with magnesium oxide to generate high-voltage static electricity and spread the fibers evenly. Fibers carrying high-voltage static electricity are statically eliminated by static eliminator (5) before being glued, then transferred to glue roller (10), and glued at glue point (9). The adhesive used in this embodiment is KRATON G- 1650 is dissolved in mixed solvent (hexane: diethyl ether: ethyl acetate = 5: 0.5: 1, then add terpene resin and antioxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com