Valve structure of carburator needle valve

A carburetor and valve technology, applied in carburetors, machines/engines, engine components, etc., can solve problems such as the impact of engine work, difficult processing, and increased production costs, achieving low production costs and good closing effect. , the effect of reducing processing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

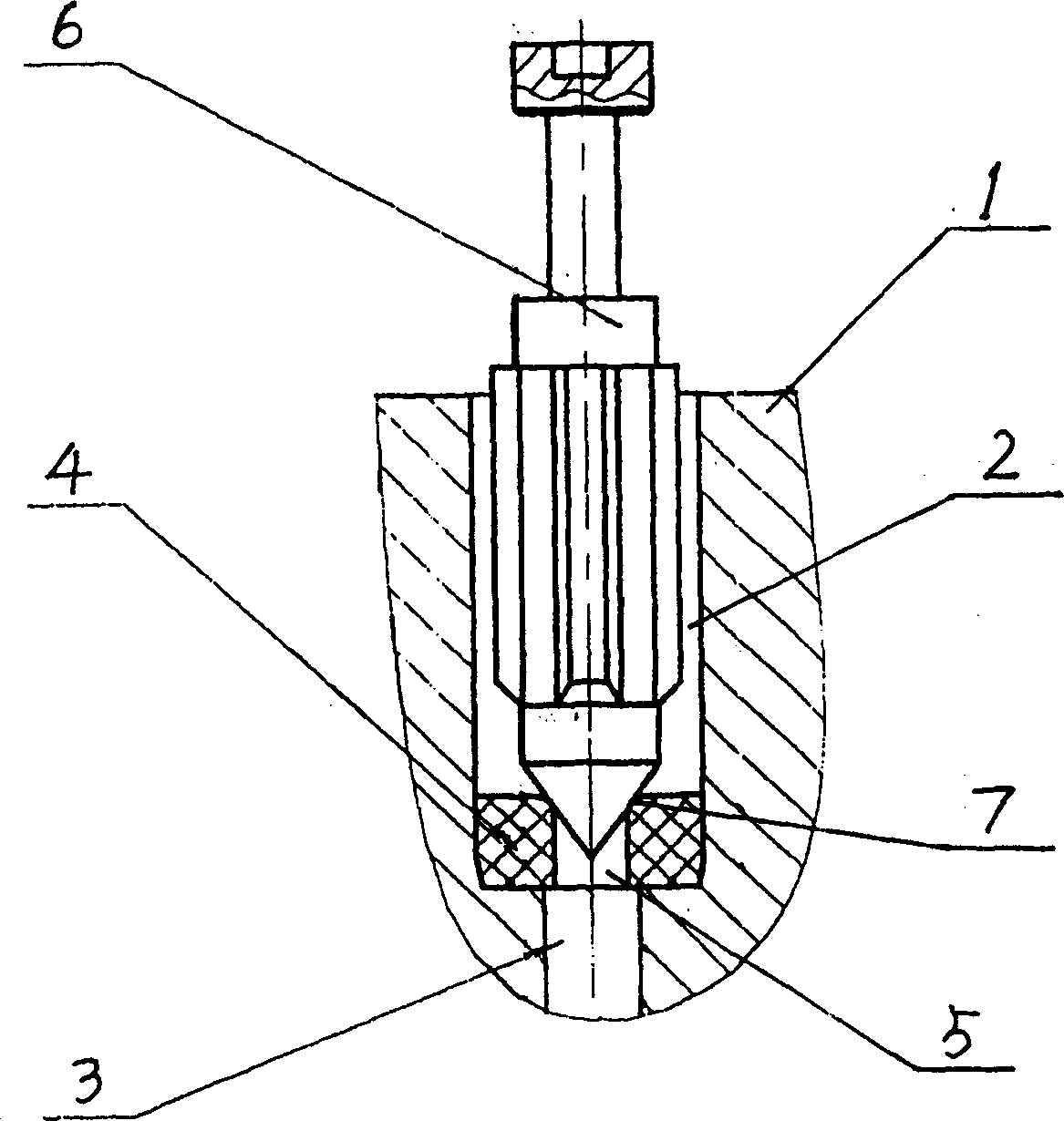

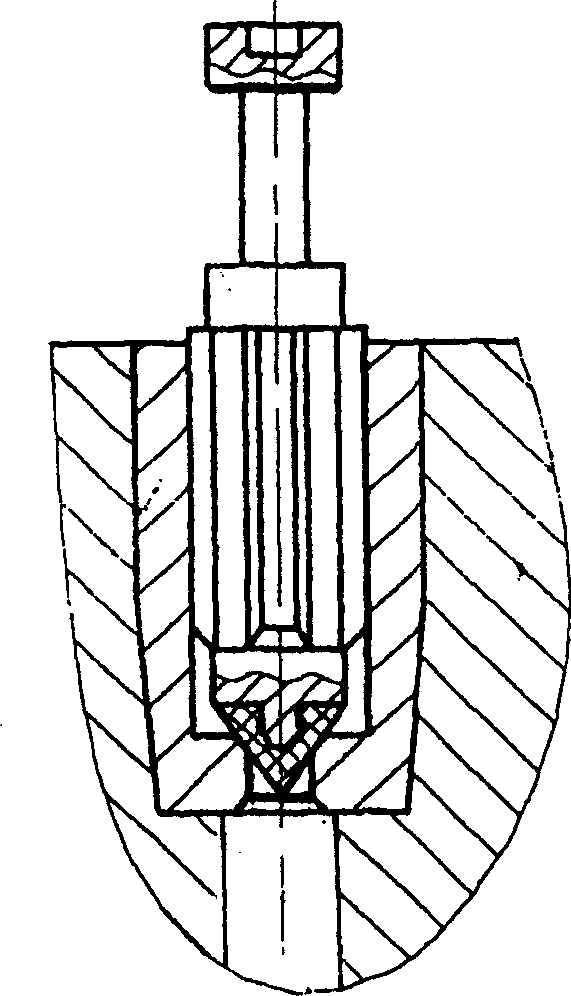

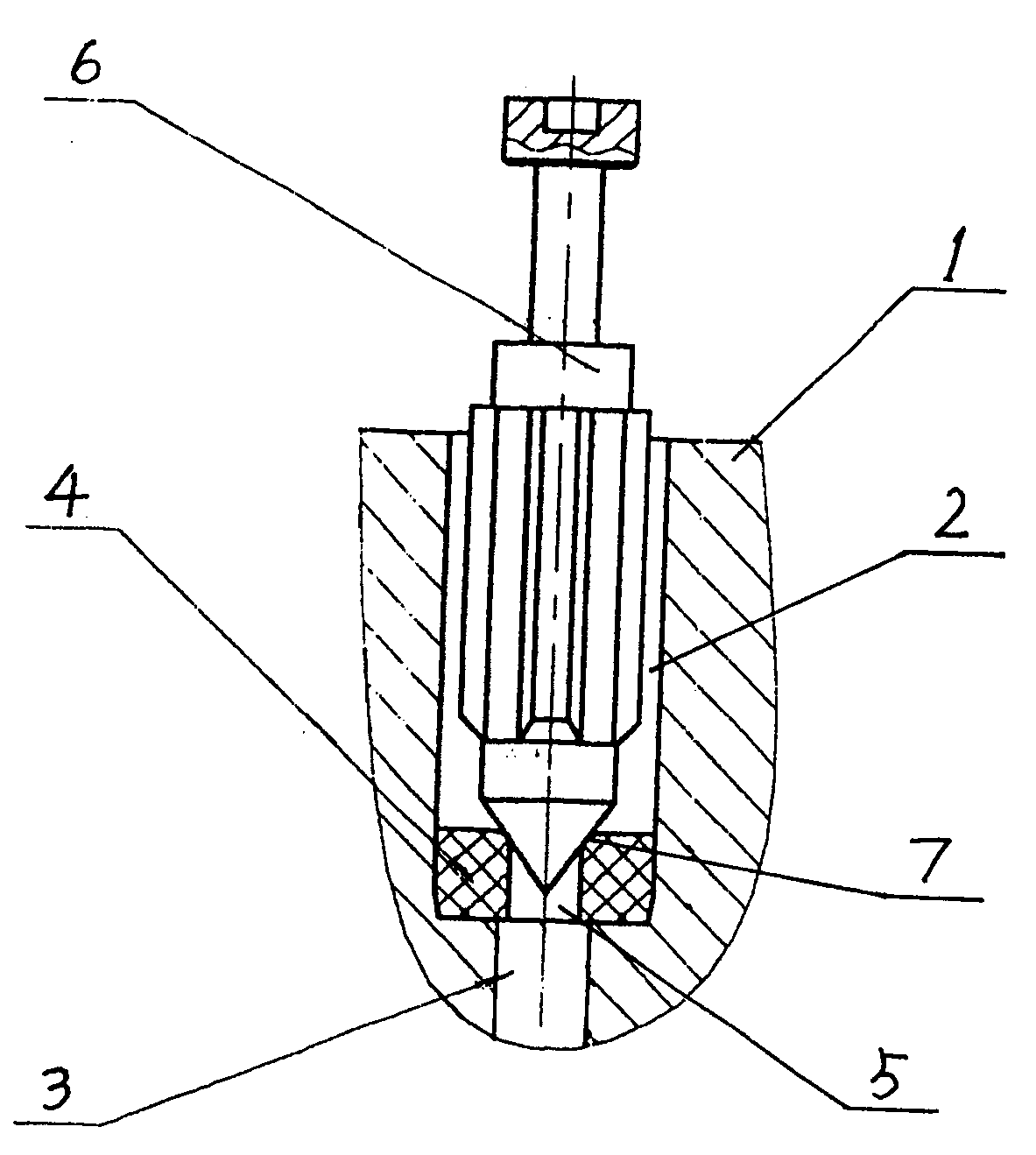

[0009] The embodiment of the present invention is described in detail below in conjunction with accompanying drawing: comprise that valve body (1) is provided with same central axis and is connected with big hole (2), small hole (3), and the bottom of big hole (2) is placed with rubber valve Seat (4), rubber valve seat (4) is made by rubber casting, is provided with through hole (5) in the middle so that large hole (2) and small hole (3) are connected, and the cone that is provided with on through hole (5) The shape surface (7) is directly pressed by a precise mold. Compared with the assembly requirements of the copper valve seat, the processing technology of the rubber valve seat is much simpler, and the accuracy is easier to guarantee. The valve stem (6) is installed in the large hole (2). The valve stem (6) is a copper rod, and one end is directly turned into a tapered valve, which is not only easy to process but also easy to meet the requirements of precision. It is also e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com