Roller mill

The technology of roller mill and roller hammer is applied in the field of material grinding device, which can solve the problems of inconvenient disassembly and maintenance, low grinding efficiency and large volume, so as to improve grinding quality and work efficiency and reduce maintenance work Strength, effect of improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

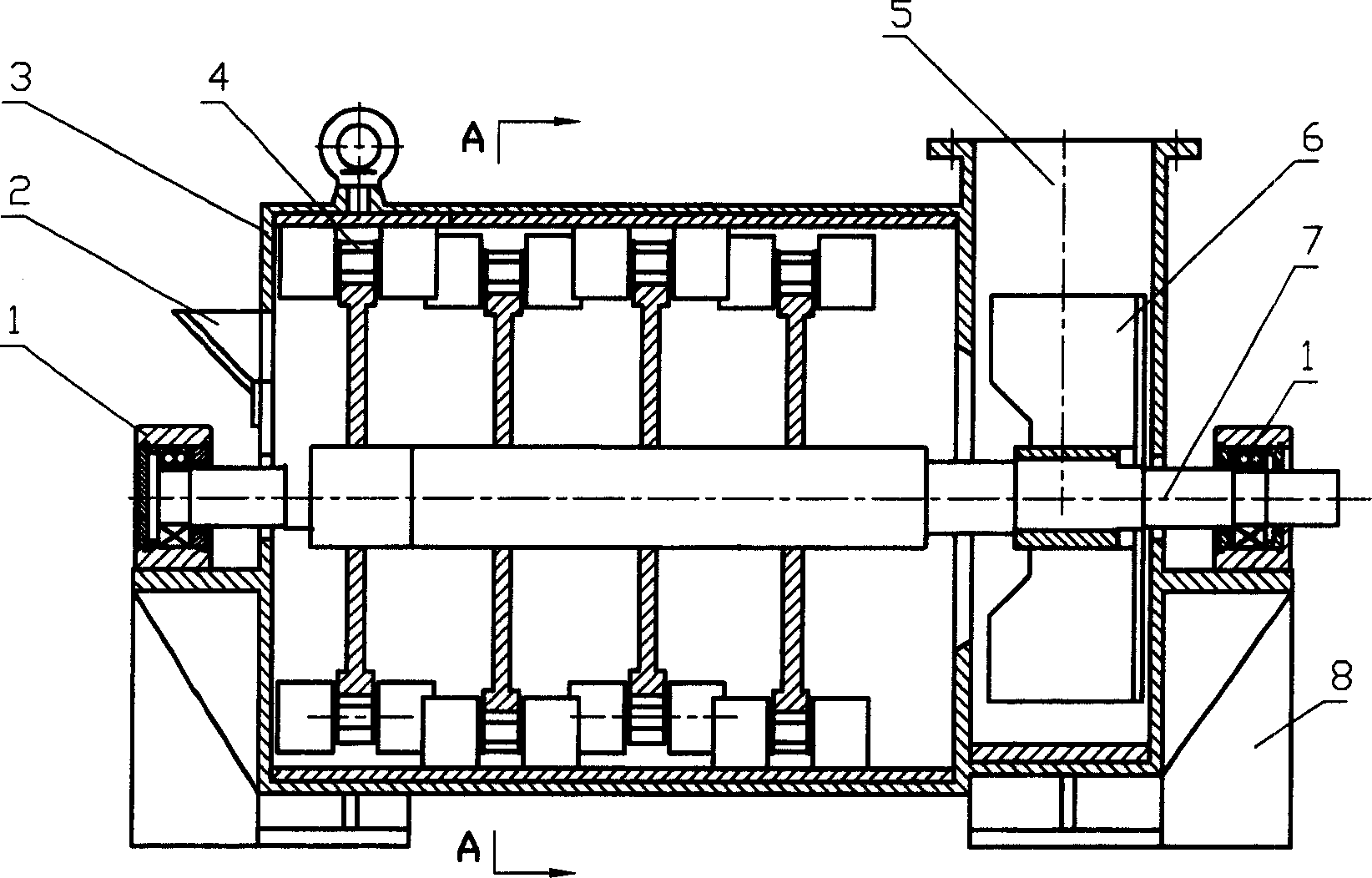

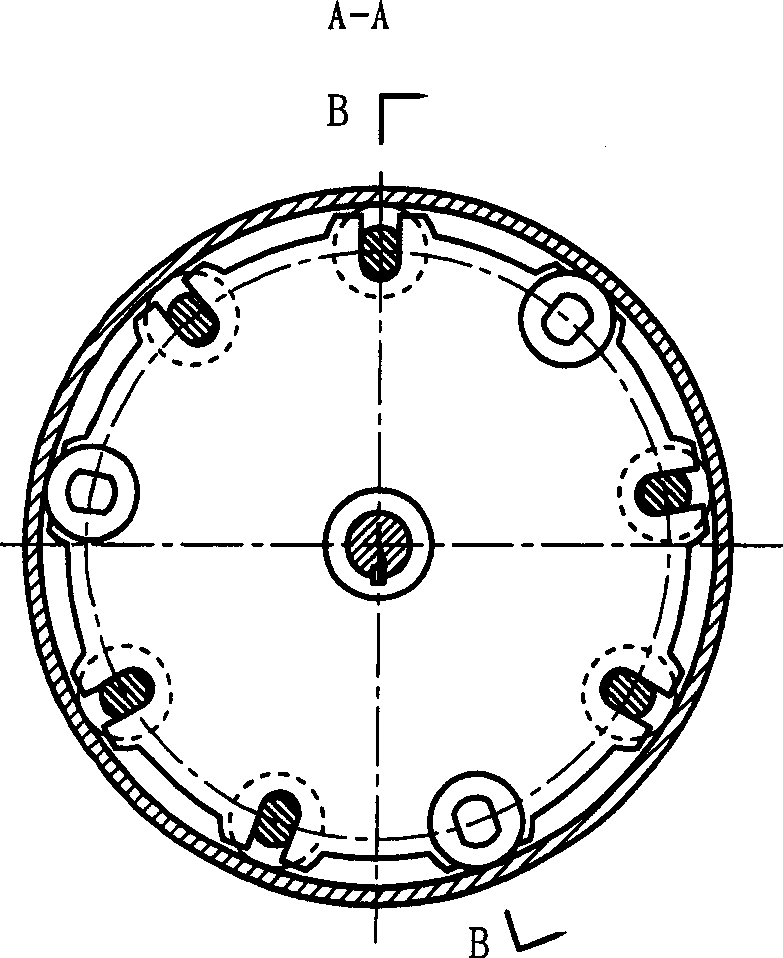

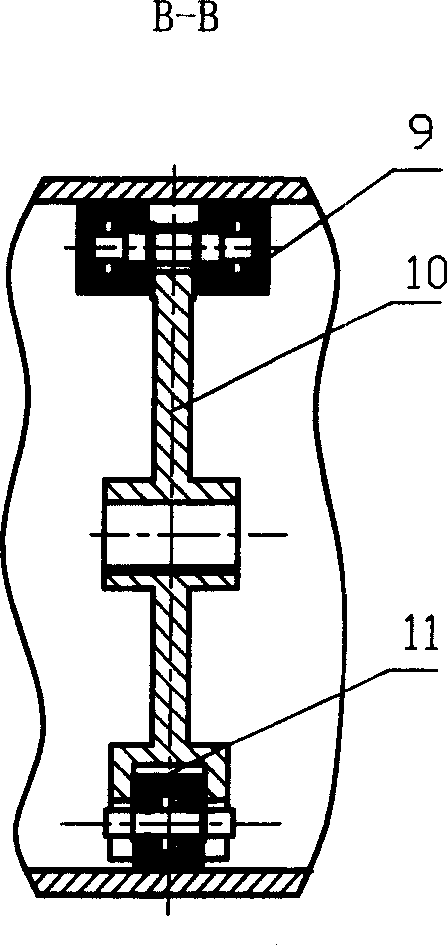

[0019] according to figure 1 -8 Describe the concrete structure and working process of the present invention in detail. The device includes an upper body 3 with a feed inlet 2 with a built-in compartment, a lower body 8 with a bearing seat 1, a roller hammer 4 assembled therein, and a fan 6 of a blower fan. Wherein the body is provided with roller hammers 4 in the compartment close to the feed port 2, and each roller hammer is assembled in the radial opening groove of the hanging roller turntable 10 periphery through pin shafts 13. The specifications and quantity of the roller hammer 4 should be determined according to actual use requirements. The roller hammer 4 can be processed into a hollow roller or a solid roller according to the specifications of the equipment and the requirements of use. One roller hammer can be arranged on each pin shaft, and two roller hammers can also be arranged on each pin shaft. When the roller hammer is a hollow roller, as shown in FIGS. 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com