Rotating disc type battery edge ironing equipment

A turntable type battery technology, applied to battery pack parts, circuits, electrical components, etc., can solve problems such as easy burns for employees, insufficient stability of clamping batteries, affecting the effect and quality of ironing, and occupying space Small size, improved production efficiency, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

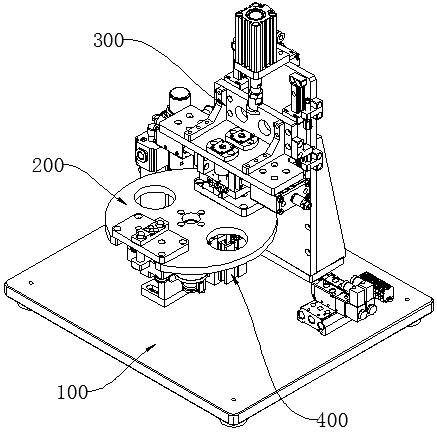

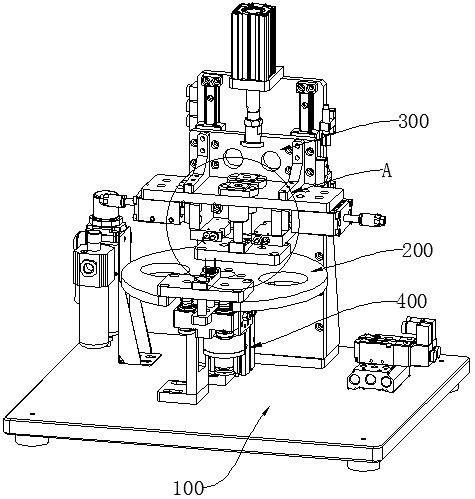

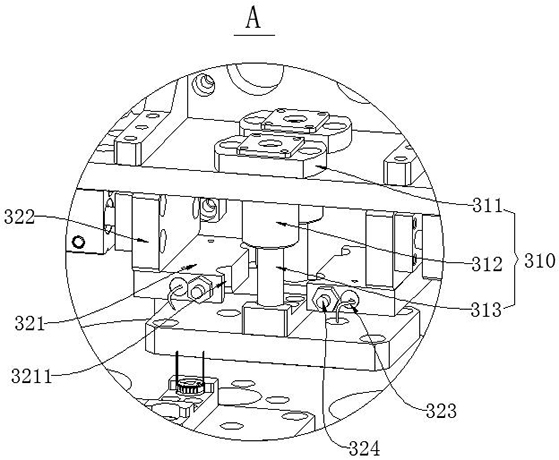

[0037] refer to Figure 1 to Figure 7 , a non-limiting embodiment of the present invention, a turntable battery ironing device, including a base 100, the base 100 is provided with a turntable mechanism 200, an ironing mechanism 300 and a jacking mechanism 400, and the ironing mechanism 300 is located at One side of the turntable mechanism 200, the jacking mechanism 400 is located below the turntable mechanism 200, the turntable mechanism 200 includes a turntable body 210, and the turntable body 210 is provided with two stations distributed at intervals, each station Product fixtures are provided on the top, and the product fixture includes a positioning fixture 220 for placing and positioning the battery, and a jacking fixture 230 located below the positioning fixture 220 and used for jacking up the battery. The bottom of the jacking fixture 230 is in contact with the The jacking mechanism 400 is connected; in this embodiment, the turntable mechanism 200 also includes a turnta...

Embodiment 2

[0046] refer to Figure 1 to Figure 7 , a non-limiting embodiment of the present invention, a method for ironing soft-packed batteries with a turntable type, the method is a method for ironing soft-pack batteries using the above-mentioned ironing equipment, and specifically includes the following steps,

[0047] S1: Start the equipment, start the ironing mechanism 300, and preheat the ironing assembly 320 to a predetermined temperature; specifically, the control system controls the heating tube 323 to be energized, and the heating tube 323 starts to work until the temperature sensor 324 senses the ironing block After the temperature of 321 reaches the predetermined temperature, the temperature sensor 324 feeds back the sensed temperature to the control system, and the control system controls the heat pipe 323 to suspend work, and controls the temperature of the edge ironing block 321 at the predetermined temperature;

[0048] S2: When the ironing mechanism 300 is preheating, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com