Well washing method of hierarchical water injection well and its underwell tubular column

A layered water injection and downhole string technology, applied in the direction of wellbore/well components, drill pipe, casing, etc., can solve the problems of water injection layer collusion, pressure difference between layers, failure to achieve the purpose of layered water injection, etc. , to achieve the effect of reducing production cost, improving reliability and improving water injection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

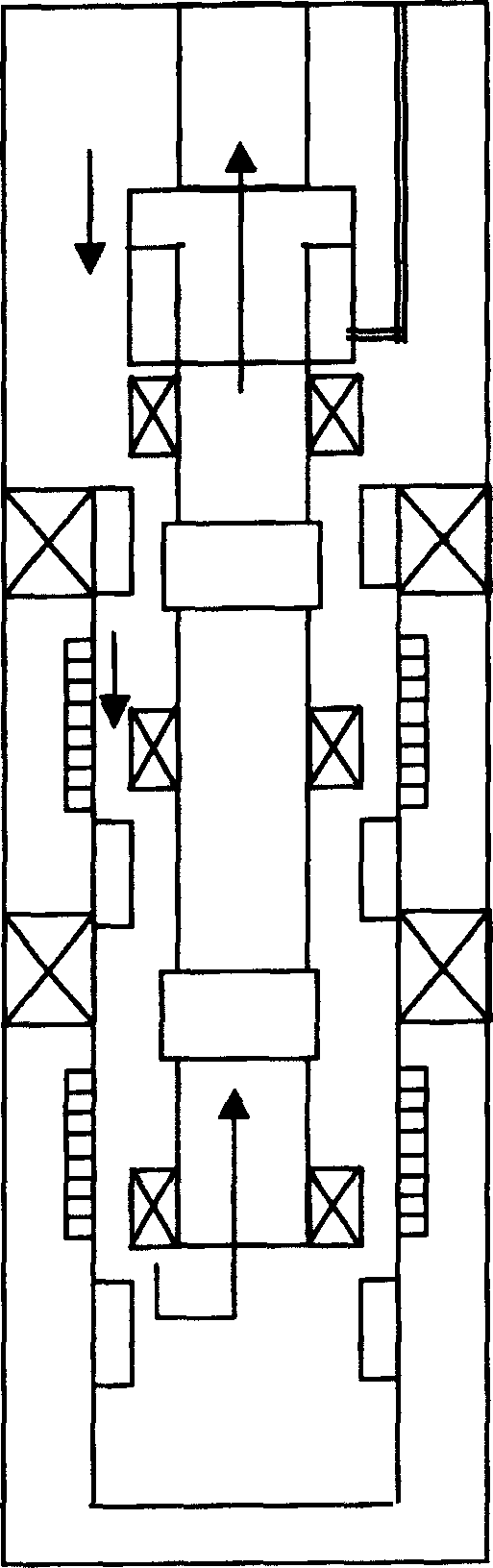

[0014] Below in conjunction with accompanying drawing, the present invention is described in further detail: see figure 2 , the well flushing method of layered water injection wells, the water injection string is run into the layered string, the well flushing water flows down from the oil casing annulus, the water injection string is lowered into the layered string, and the passage between them is controlled by the sealing mechanism Sealing; the well flushing water flows downward from the oil casing annulus, flows through the open channel, and returns upward from the bottom pipe of the water injection string. In the well flushing method of the present invention, the passage is opened by lifting and unloading the water injection string before the well flushing, and the passage is closed by putting and lifting the water injection string after the well flushing.

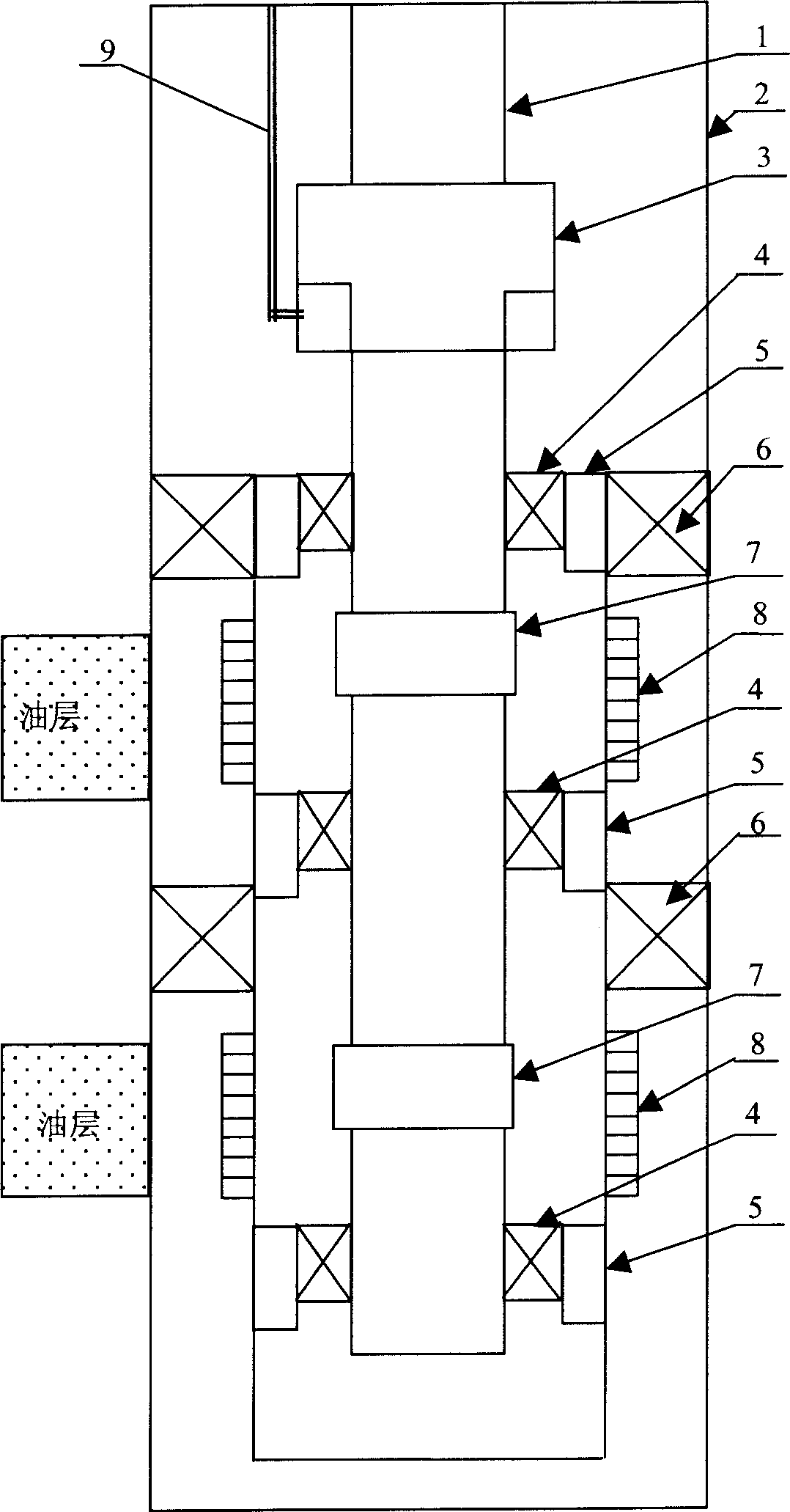

[0015] The downhole string of the layered water injection well using the above well cleaning method, see figure 1 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com