Suction unit for vacuum thermal insulation board

A technology of vacuum heat insulation panel and suction device, which is applied in the direction of protecting pipelines, heat exchange equipment and heat preservation through heat insulation, etc., can solve the problems such as the decrease of the effective suction capacity of the loading equipment, the limited capacity of adsorbing organic gas, and the low adsorption rate. , to ensure the effectiveness, increase the adsorption rate, and improve the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The accompanying drawings disclose several specific embodiments related to the present invention without limitation, and the present invention will be further described below in conjunction with the embodiments.

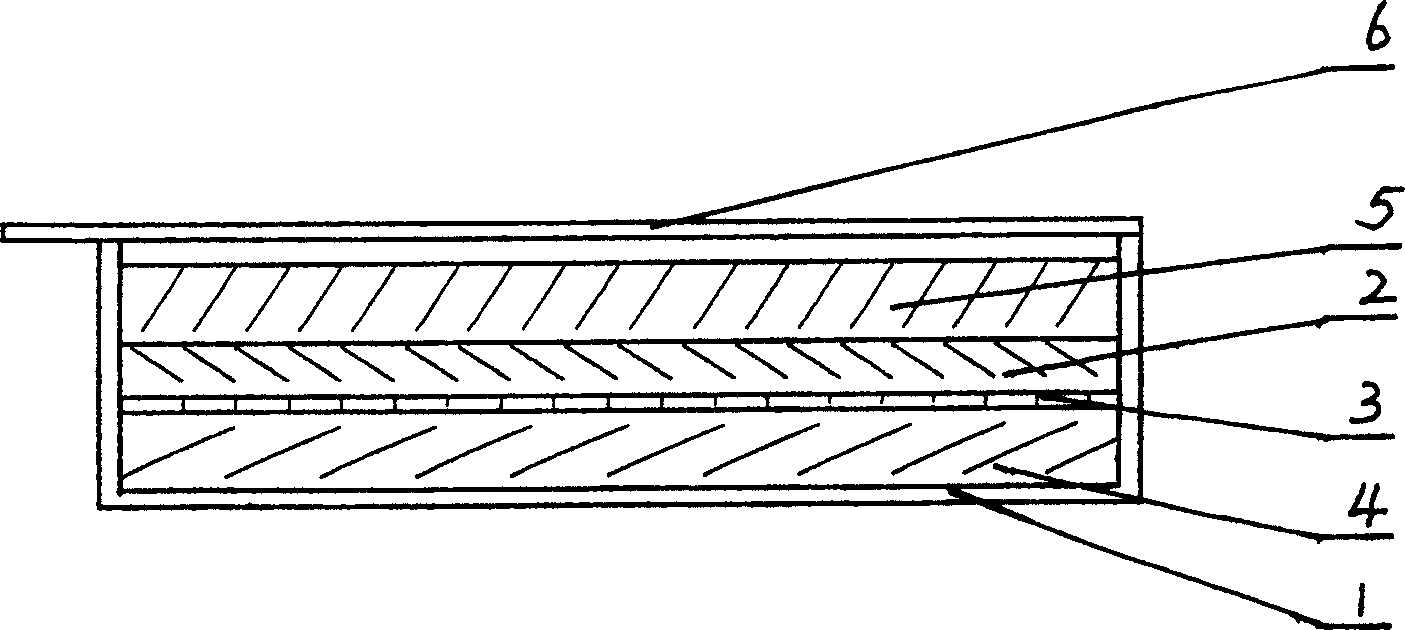

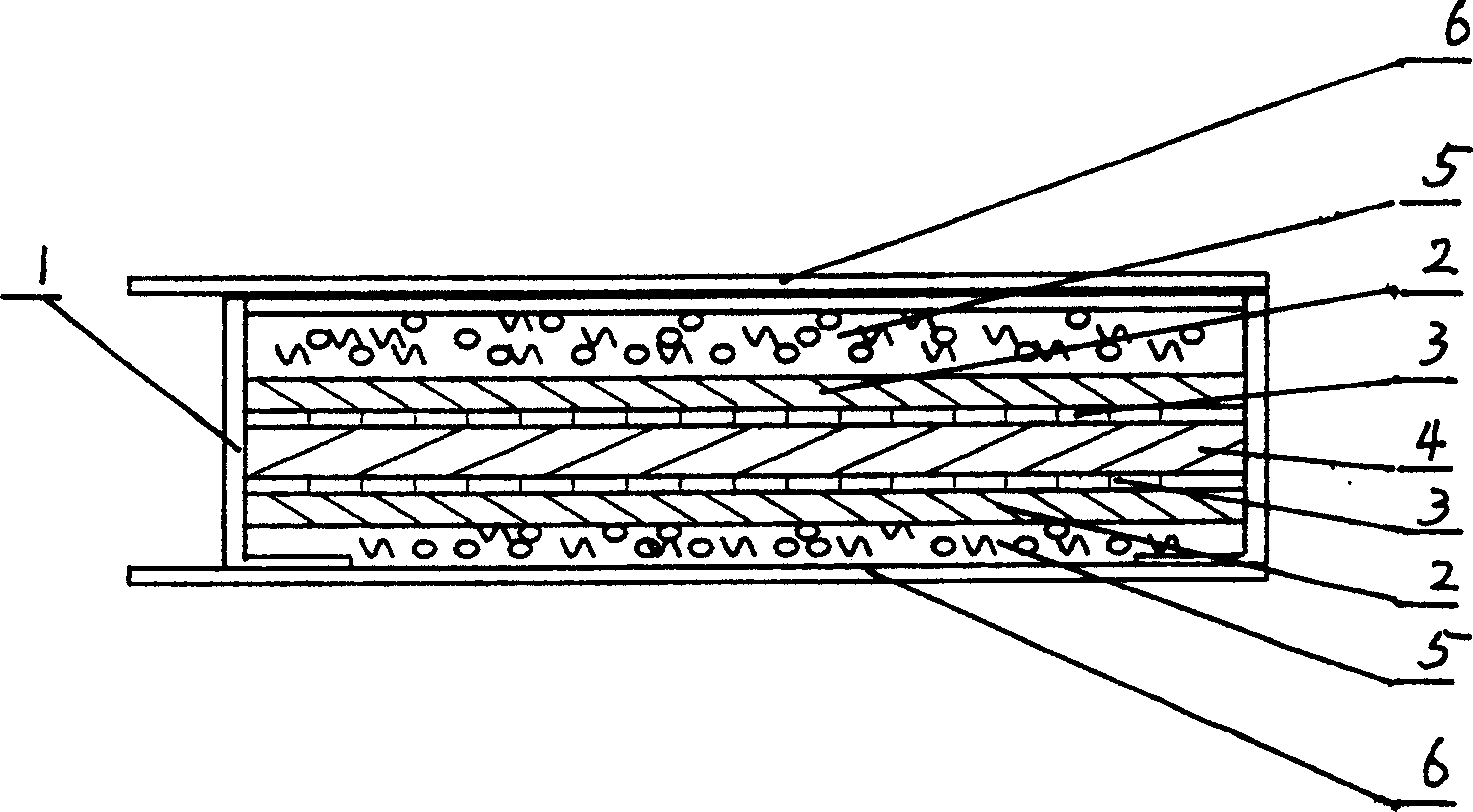

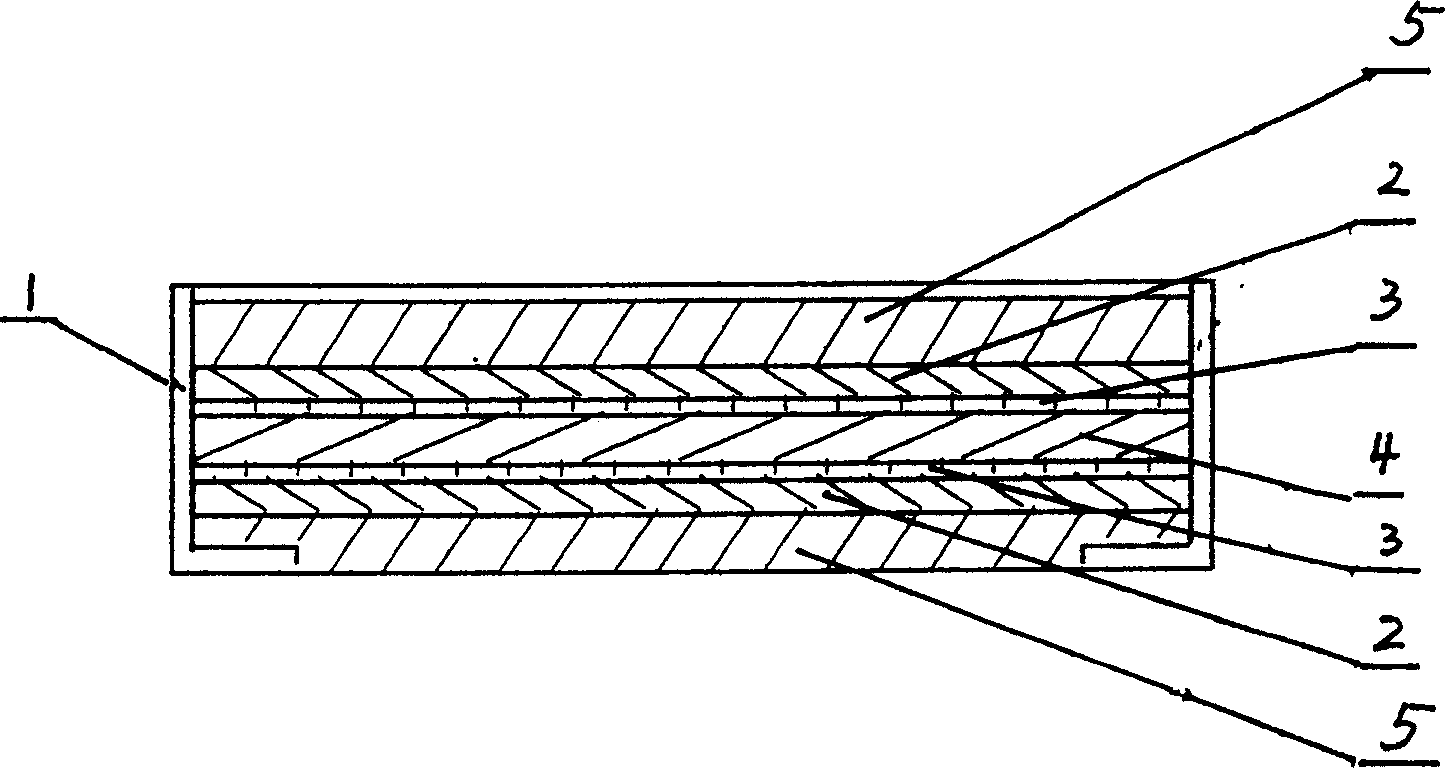

[0017] Depend on figure 1 It can be seen that the present invention includes: carrier 1, water-absorbing material, segmented material 3 and getter alloy 4, also includes organic gas absorbing layer 2, anti-expansion material and protective film 6, water-absorbing material and anti-expansion material are mixed to form a breathable layer 5, The getter alloy 4 , the organic gas absorbing layer 2 and the air permeable layer 5 are sequentially layered and placed in the carrier 1 from inside to outside, wherein a partition material 3 is provided between the getter alloy 4 and the organic gas absorbing layer 2 . The carrier 1 is a cylindrical barrel made of metal or plastic, with a diameter of 10-80 mm. The protective film 6 is placed on the edge of the carrier 1 out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com