Welding head with a sensor

A sensor and welding head technology, applied in the characteristics of welding rods, welding equipment, soldering irons, etc., can solve the problems of the sensing wire falling off, inconvenient welding operation, deformation, etc., and achieve the effect of prolonging the service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

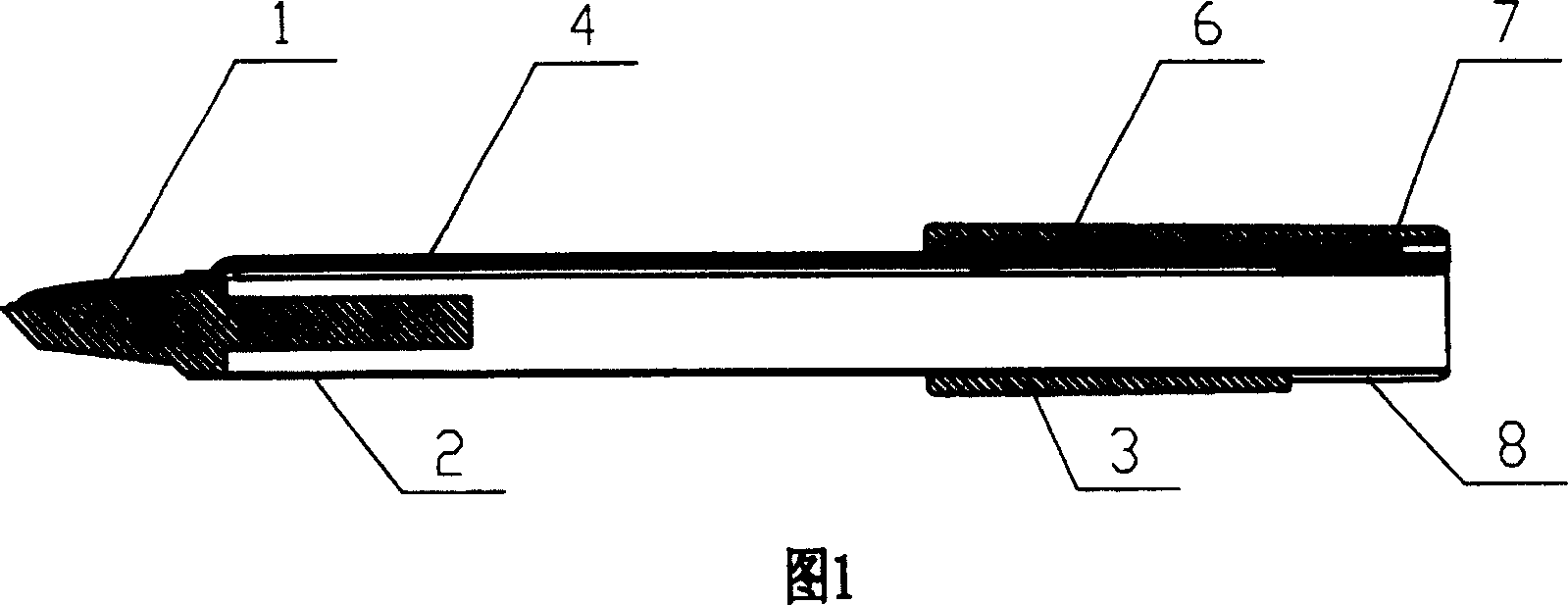

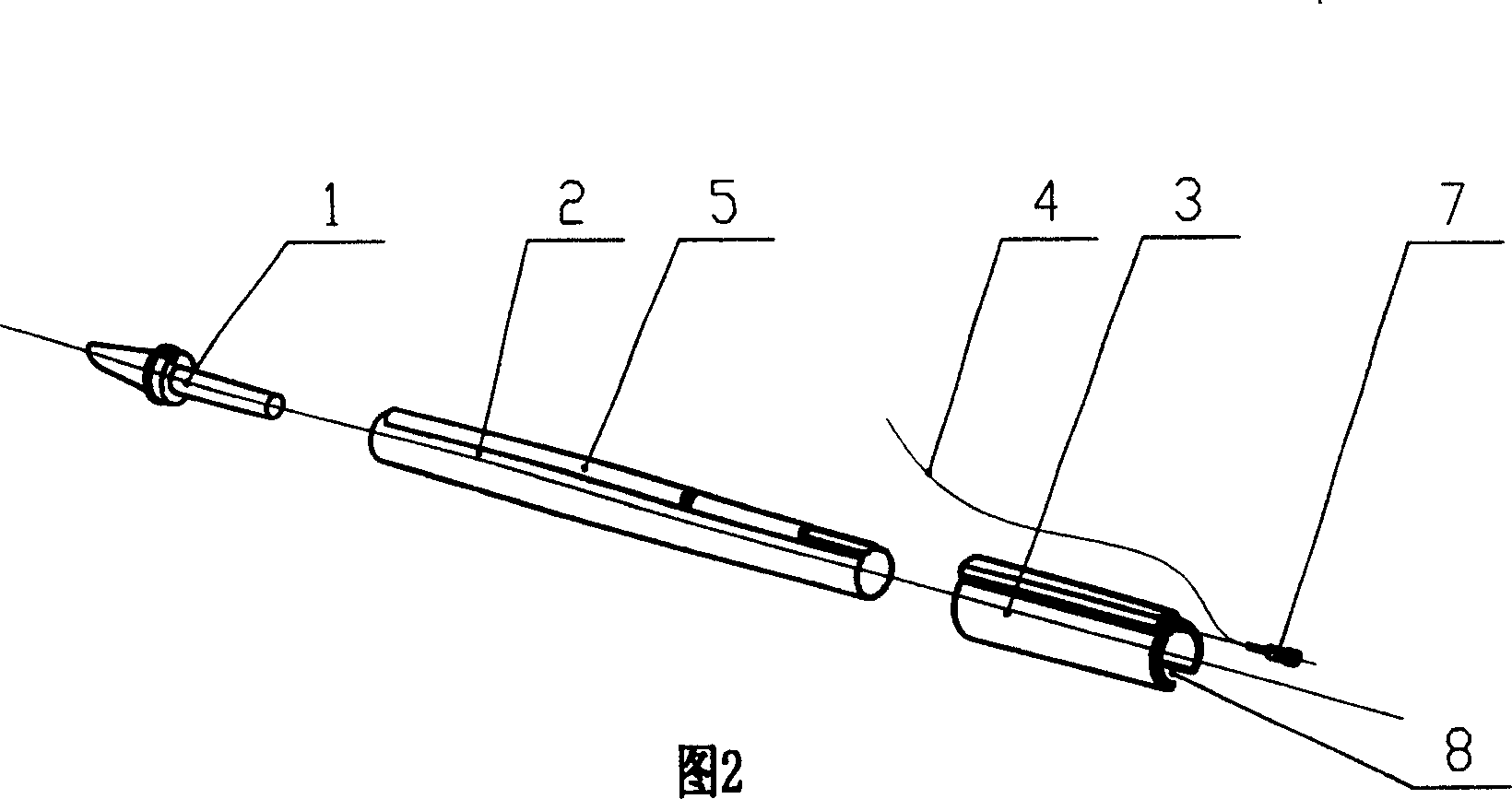

[0013] A welding head with a sensor of the present invention has a welding head 1, a steel pipe for the welding head 2, a steel pipe plastic part 3 for the welding head, and a sensing wire 4. The welding head 1 is installed on one end of the steel pipe 2 for the welding head, and the steel pipe plastic part for the welding head 3 is installed on the other end of the welding head steel pipe 2. In order to effectively protect the sensing wire, a long strip-shaped protrusion is arranged axially on the outer wall of the welding head steel pipe 2. The inside of the protrusion is hollow to form a sensing wire cavity 5. The sensing wire 4 passes through the sensing wire chamber 5 , and the sensing wire is effectively protected by the sensing wire chamber 5 . In order to cooperate with the installation of the steel pipe of the welding head, a protrusion is also arranged on the plastic part 3 of the steel pipe of the welding head, and a slot 6 matching with the sensing wire cavity 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com