Sterilized antiviral respirator and preparation method

An anti-virus and mask technology, applied in the field of masks, can solve the problems of causing other diseases, losing the physiological function of the nasal cavity, and stuffiness, and achieve the effect of preventing virus infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

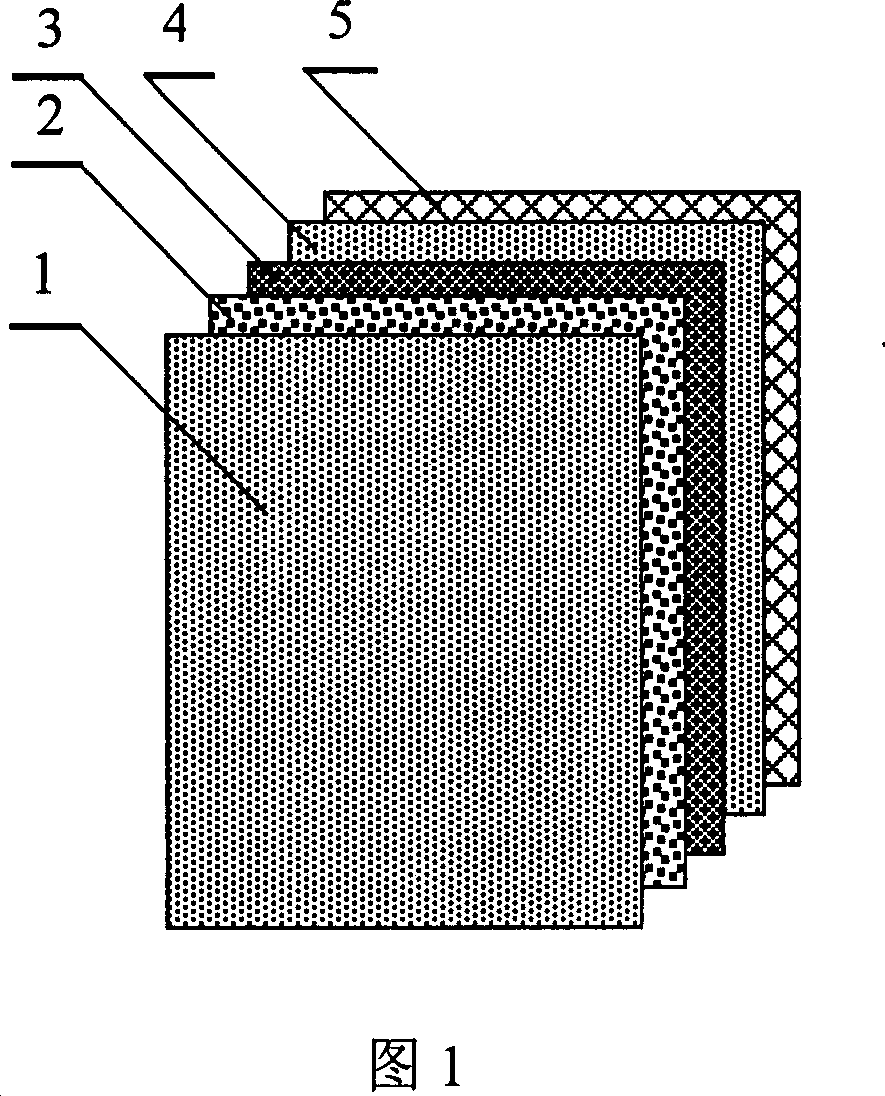

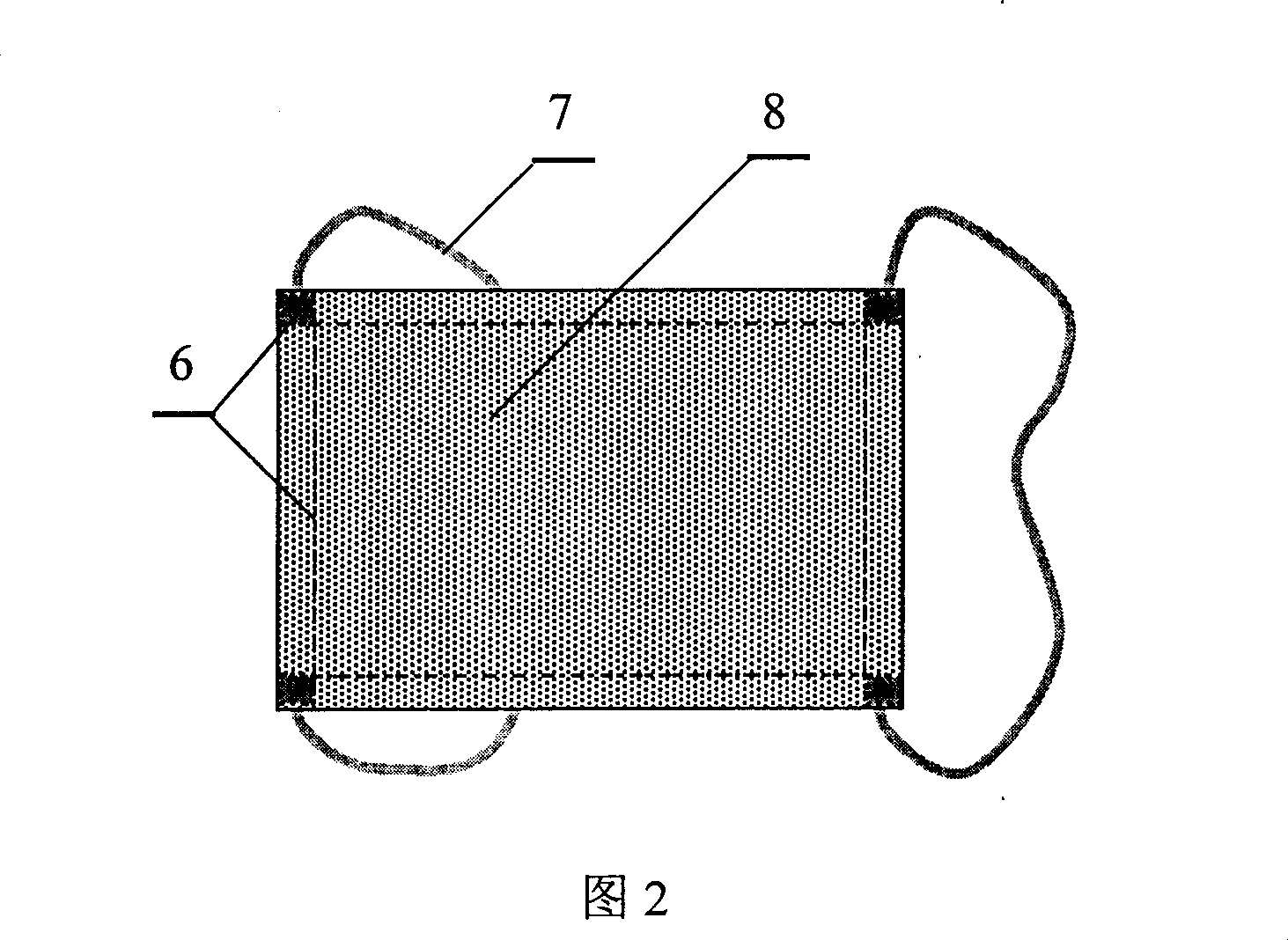

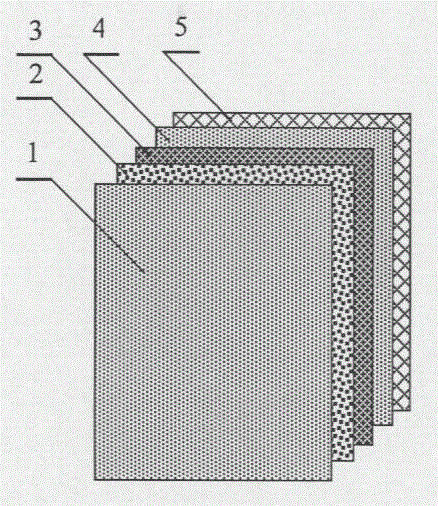

[0046] See Figure 1 and Figure 2. One layer of commercially available superamphiphobic barrier fabric layer 1, one layer of sterilizing and disinfecting fabric layer 2, one layer of absorbent antibacterial fabric layer 3, one layer of commercially available superamphiphobic barrier fabric layer 4 and two layers of commercially available contact protection The fabric layers 5 are stacked successively from the outside to the inside, and the materials are all cotton gauze. Cut into a rectangle of 18cm * 12cm, sew it up with sutures 6 along the inner 0.5cm of the edge, and then sew four corner bands 7 at four corners to obtain the mask 8 of the present invention. The air permeability of the mask made is very good, within the national standard. The antibacterial test adopts the Quinn method. Take one layer of sterilization and disinfection layer 2 and one layer of adsorption antibacterial layer 3, drop the bacterial liquid directly on the two layers of cotton yarn, cover with cul...

Embodiment 2

[0049] See Figure 1 and Figure 2. One layer of commercially available superamphiphobic barrier fabric layer 1, two layers of sterilization and disinfection fabric layers 2, one layer of absorbent antibacterial fabric layer 3, one layer of commercially available superamphiphobic barrier fabric layer 4 and two commercially available contact protection fabric layers 5. The materials are all non-woven fabrics and are stacked together sequentially from the outside to the inside. Cut into a rectangle of 18cm * 12cm, sew it up with sutures 6 along the inner 0.5cm of the edge, and then sew four corner bands 7 at four corners to obtain the mask 8 of the present invention. The air permeability of the mask made is very good, within the national standard. The antibacterial test adopts the Quinn method. Take two layers of sterilization and disinfection layer 2 and one layer of adsorption antibacterial layer 3, drop the bacteria solution directly on the three-layer non-woven fabric, cover...

Embodiment 3

[0052] See Figure 1 and Figure 2. One layer of commercially available superamphiphobic barrier fabric layer 1, one layer of sterilizing and disinfecting fabric layer 2, one layer of absorbent antibacterial fabric layer 3, one layer of commercially available superamphiphobic barrier fabric layer 4 and two commercially available contact protection fabric layers 5 are stacked together from the outside to the inside, the materials used are the 1st, 2nd, 4th functional fabric layers are polyester cloth, the 3rd functional fabric layer is non-woven fabric, and the 5th functional fabric layer is cotton gauze. Cut into a rectangle of 18cm * 12cm, sew it up with sutures 6 along the inner 0.5cm of the edge, and then sew four corner bands 7 at four corners to obtain the mask 8 of the present invention. The air permeability of the mask made is very good, within the national standard. The antibacterial test adopts the Quinn method. Take one layer of sterilization and disinfection layer 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com