Method and apparatus for the servicing of a working station in a textile machine

A technology for working position and maintenance device, applied in the directions of transportation and packaging, thin material handling, conveying filamentous materials, etc., which can solve the problems of winding on adjacent bobbins, troublesome processing, and hindering the unwinding of bobbins. , to increase the wrapping length and prevent random steering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

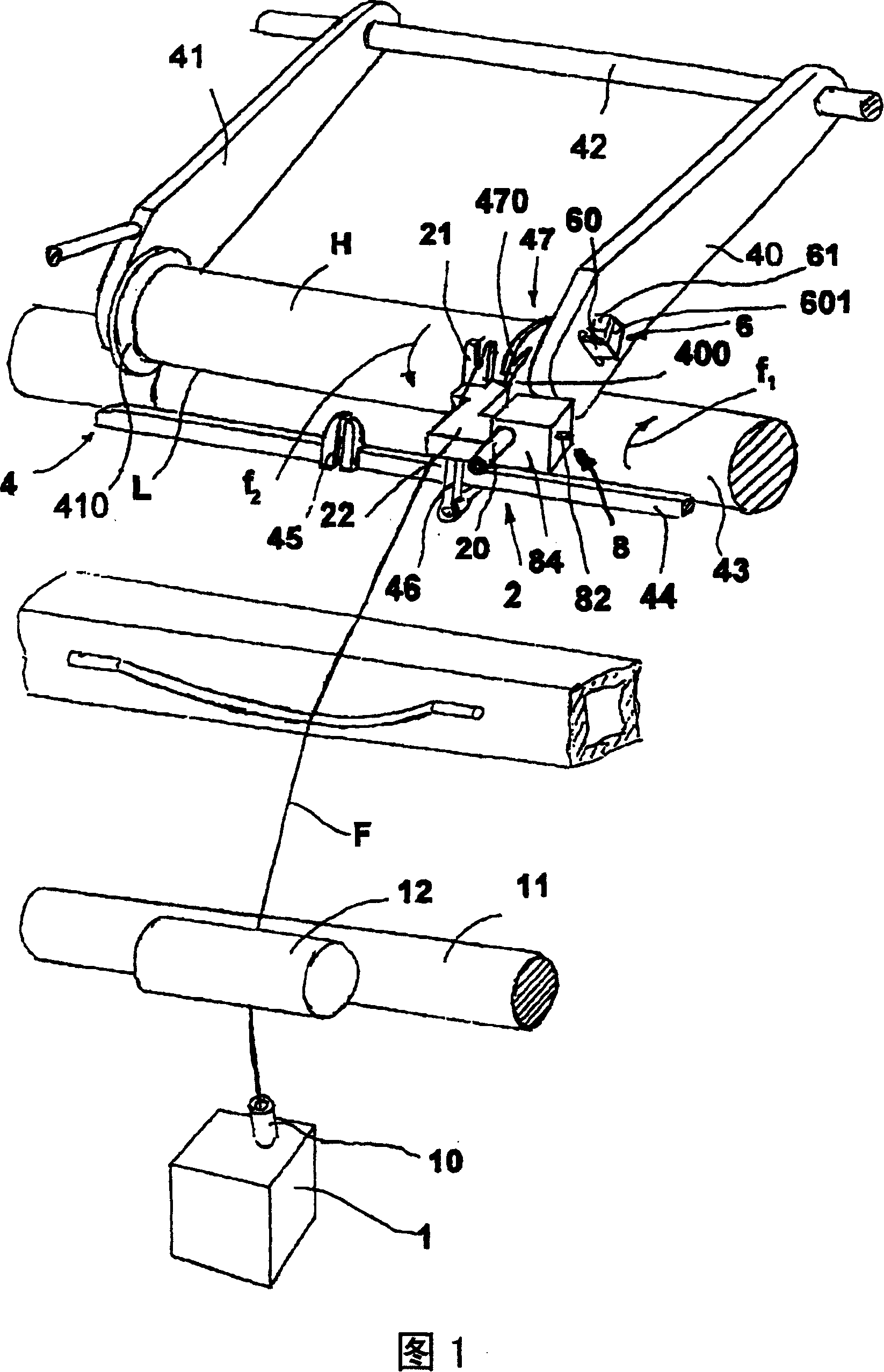

[0032] The invention can be used on different textile machines for winding a running yarn F onto an empty bobbin H ( FIG. 1 ) of eg a winding machine or an open-end spinning machine.

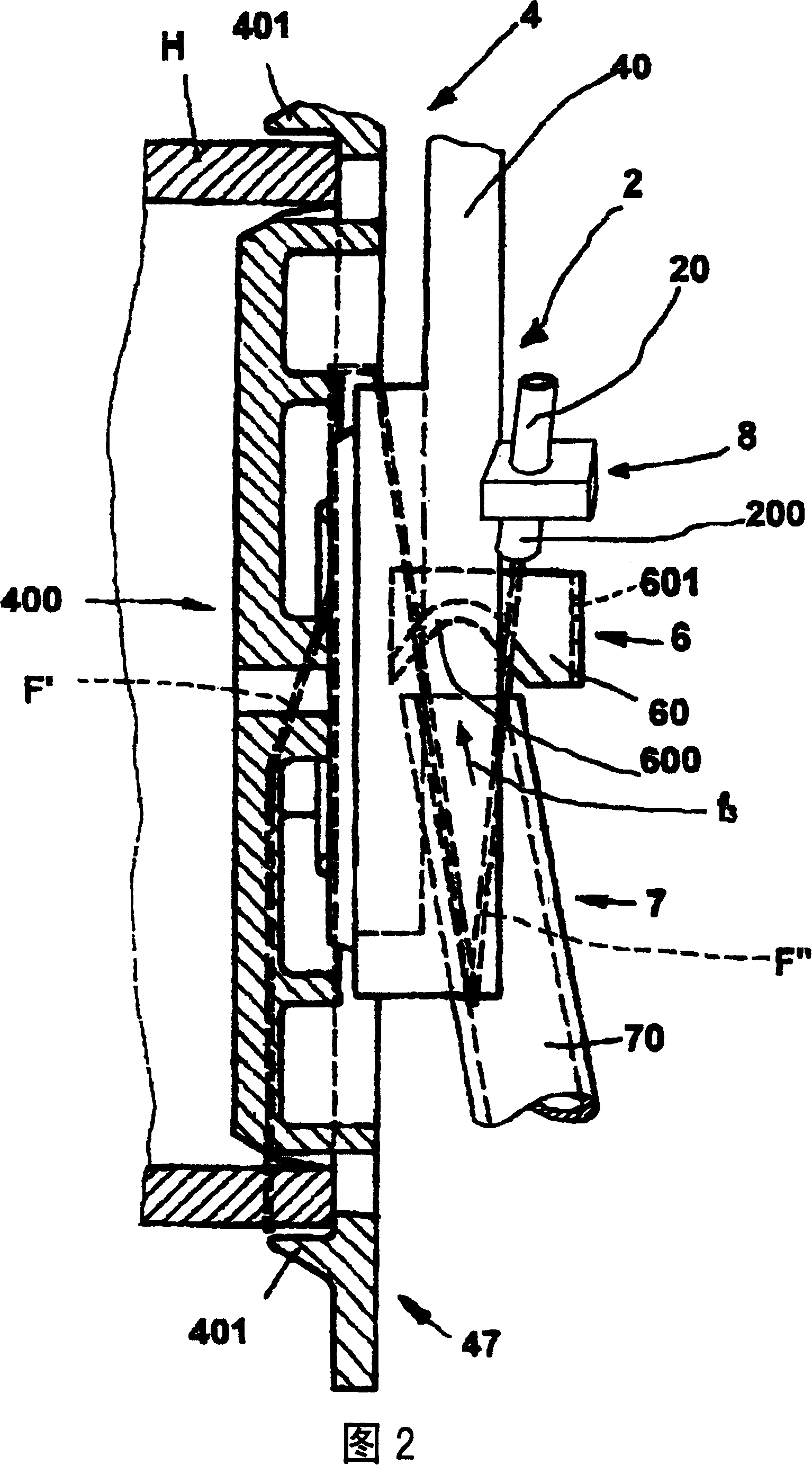

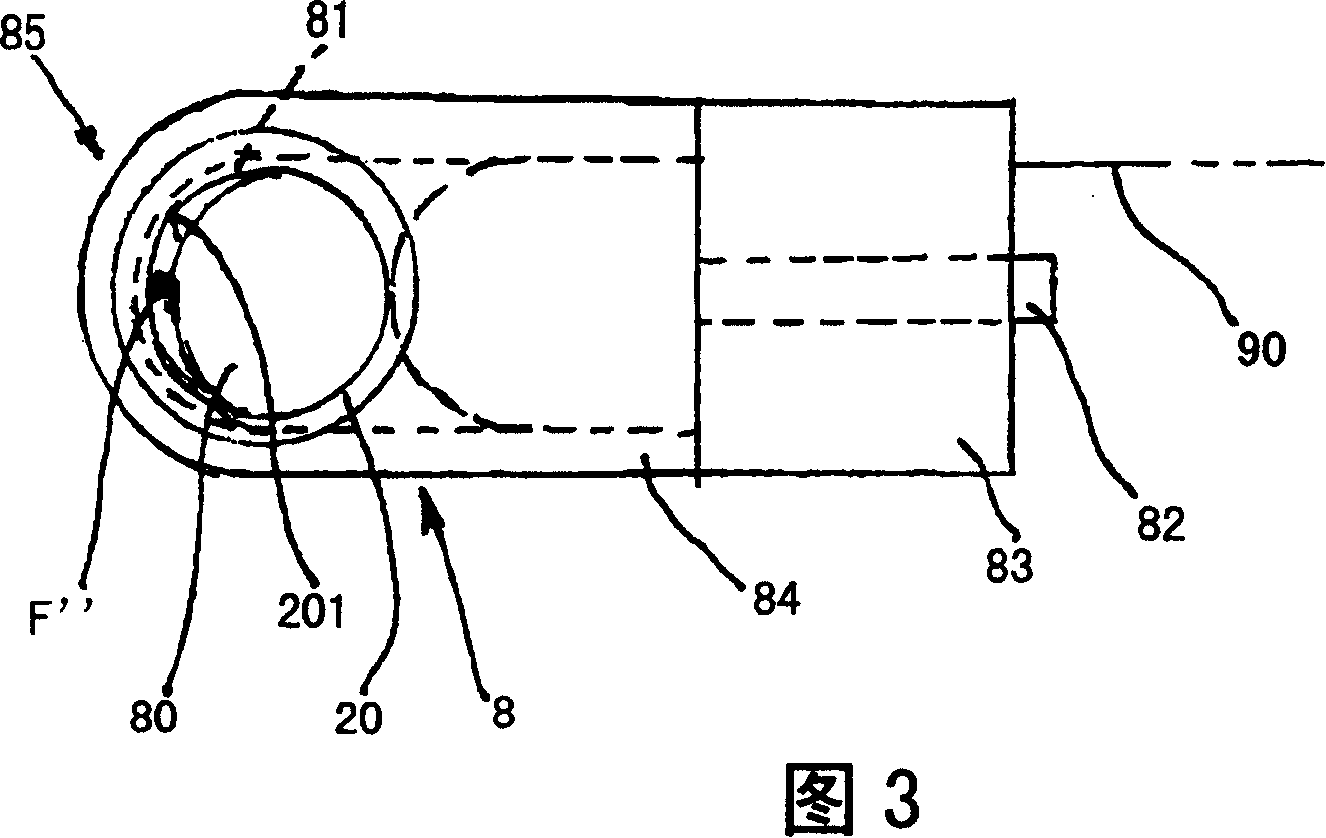

[0033] The following description relates to an air spinning machine comprising a plurality of similarly constructed air spinning devices 1 arranged side by side, each air spinning device 1 having a drawing tube 10 through which the yarn F can be passed Pulling rolls 11 , 12 are drawn out of the air spinning device 1 to be fed to the winding device 4 . The winding device 4 has two bobbin arms 40 and 41 which are pivotally supported on a shaft 42. An empty bobbin H for winding a yarn F is rotatably supported on the bobbin arms 40 and 41 by means of two bobbin discs (Hülsenteller ) 400 and 410 can be mounted between the bobbin arms 40 and 41. One of the bobbin reels is in this exemplary embodiment a bobbin reel 400 designed as a winding device 47 and thus has a plurality of stops 470 .

[0034]In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com