Casting tube, clamping device for a casting tube and casting machine

A technology for casting equipment and pouring nozzles, which is applied in the direction of casting equipment, metal processing equipment, casting molten material containers, etc., can solve problems such as unsatisfactory, expensive solutions, etc., to reduce the occurrence and/or expansion of cracks, The effect of enhancing the ability to resist cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

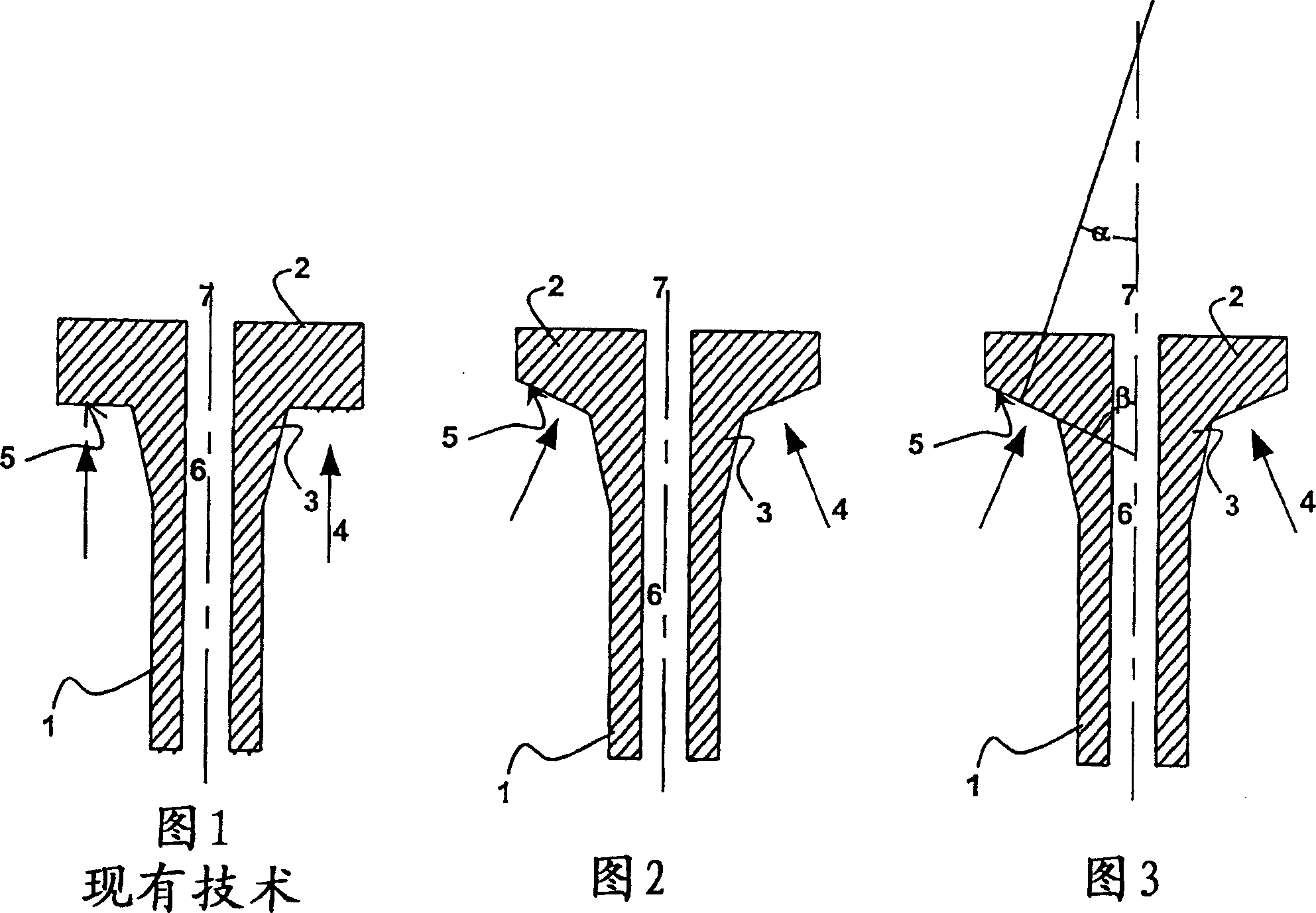

[0042] Figure 1 shows a pouring nozzle (1) according to the prior art, said nozzle comprising a plate (2) and a tubular part (3). The angle β formed between the planar bearing surface (5) and the runner axis (7) is 90°. The thrust (4) is vertical, parallel to the axis of the sprue (7). In the prior art, stresses generated in the pouring nozzle are responsible for the formation of cracks at the tip of the tubular portion (3).

[0043] Accompanying drawing 2 and accompanying drawing 3 show pouring nozzle (1) of the present invention. The plate (2) of the nozzle (1) is beveled in a specific manner. The angle β formed by the planar support surface (5) ranges from 20° to 80°, so that there is no need to increase the amount of material of the plate (2).

[0044] Figure 3 shows the angles α and β. The angle α formed between the resultant thrust force and the runner axis is 21°. The angle β formed between the planar bearing surface and the axis of the runner is 69°.

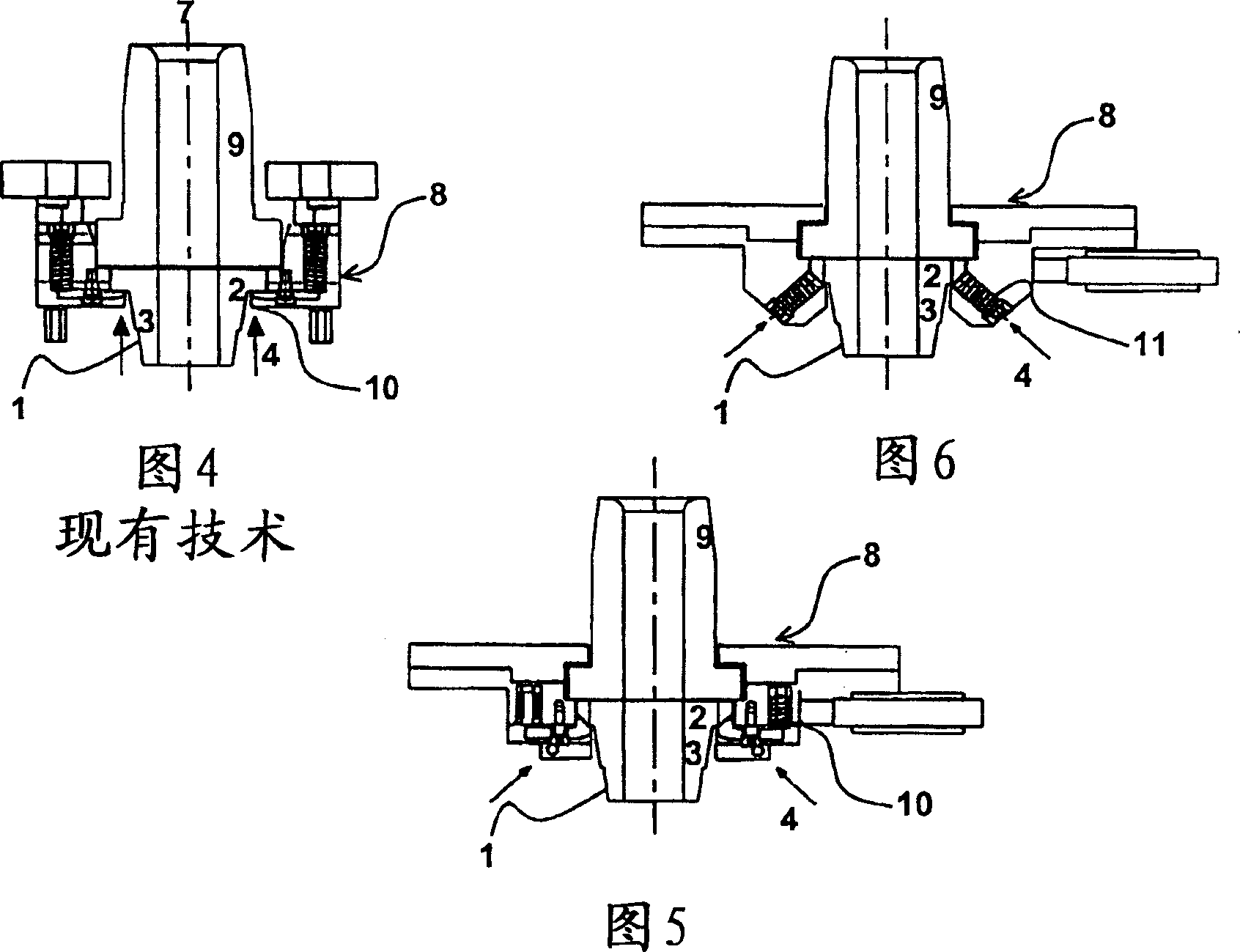

[0045] Acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com