Air cooled steam exhaustor with built-in oxygen remover

A built-in, steam exhaust technology, applied in the direction of engine components, machines/engines, chemical instruments and methods, etc., can solve the problems of poor oxygen removal effect and occupation of workshop space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

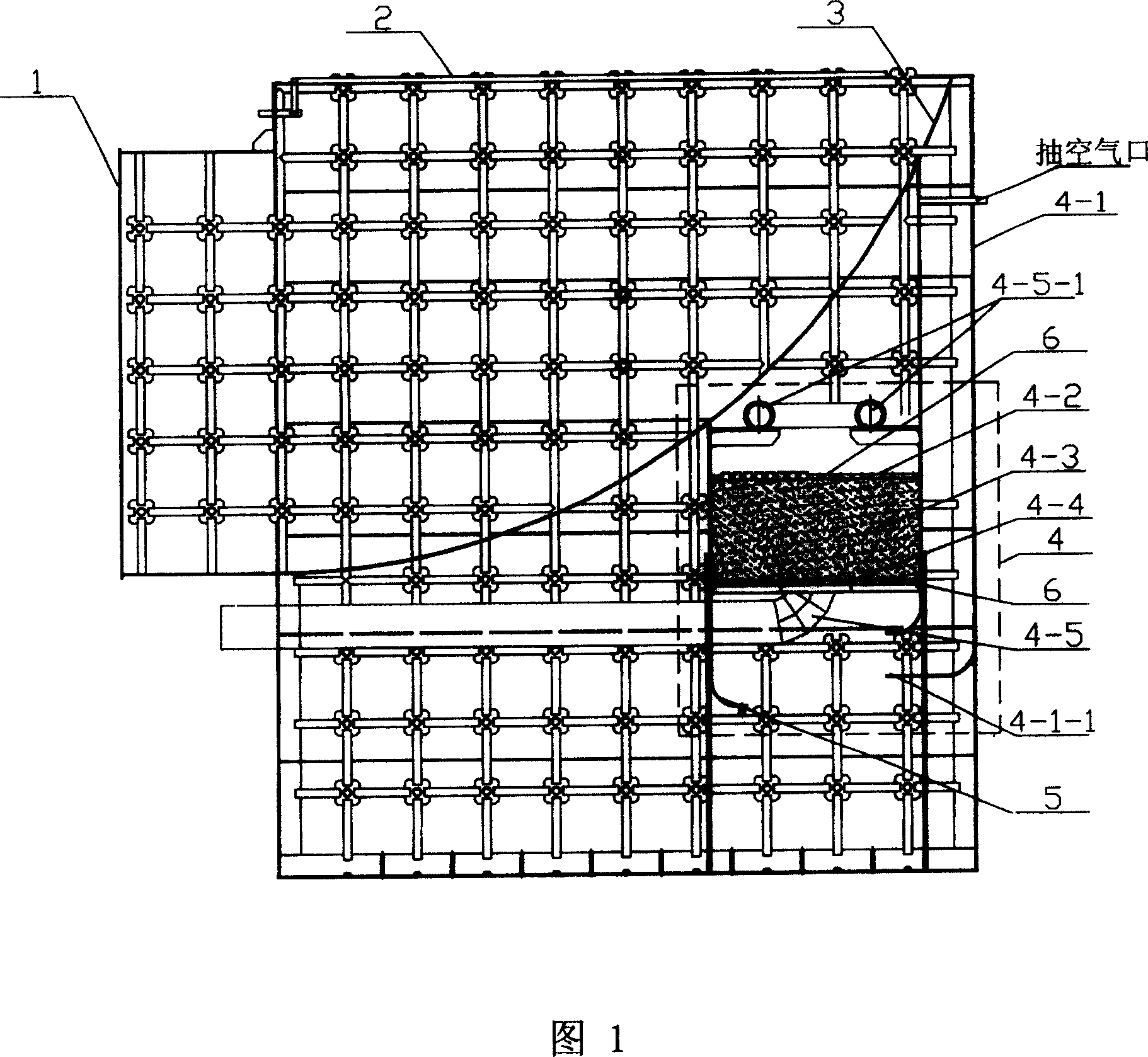

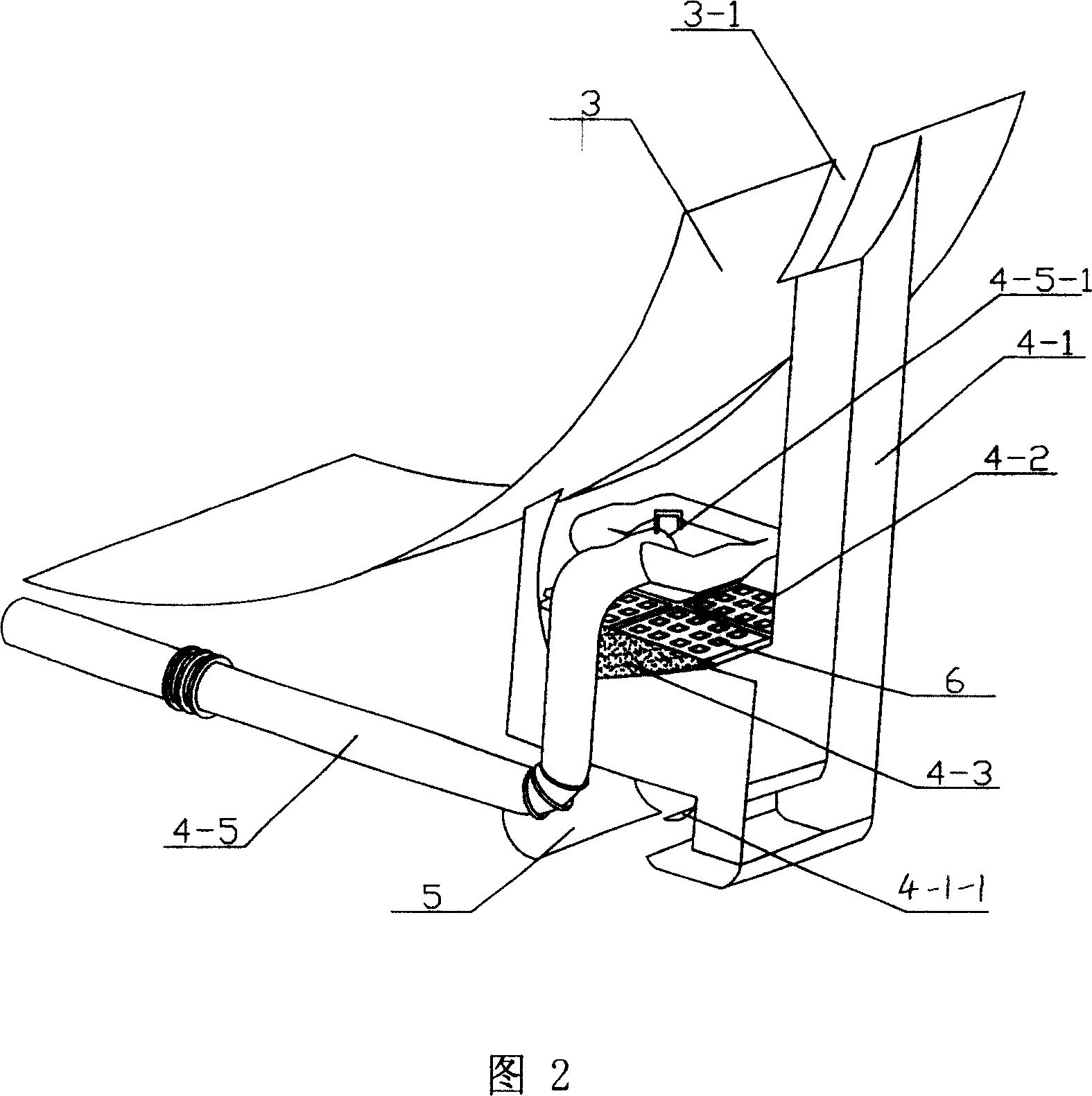

[0005] Specific embodiment 1: Referring to Fig. 1 and Fig. 2, this embodiment is an air-cooled steam exhaust device with a built-in deaeration device, which includes a steam exhaust device 1, and a condensate water replenishment spray is arranged in the steam exhaust device 1 The water pipeline 2 and the deflector 3 are also provided with a deoxygenation device 4 in the steam exhaust device 1, and the deoxygenation device 4 includes a heating steam channel 4-1, an upper shower net 4-2, and a packing layer 4-3 , the lower shower net 4-4 and the condensed water pipe 4-5, the upper shower net 4-2 and the lower shower net 4-4 are provided with holes 6 for water supply and gas passing through, and the packing layer 4-3 Set between the upper shower net 4-2 and the lower shower net 4-4, the water spray port 4-5-1 of the condensate pipe 4-5 is set above the upper shower net 4-2, and the steam channel is heated The air jet port 4-1-1 of 4-1 is arranged below the lower shower net 4-4. ...

specific Embodiment approach 2

[0007] Specific embodiment two: with reference to Fig. 2, be provided with opening 3-1 at the upper end of deflector 3, the upper end of described heating steam channel 4-1 is arranged below opening 3-1, the opening on the deflector 3 can be A sufficient amount of steam enters the heating steam passage 4-1; a steam baffle 5 is provided on the front and lower side of the air jet 4-1-1 of the heating steam passage 4-1, and the steam baffle can ensure that the heating steam passage 4-1 The steam that comes out is better sprayed into packing layer 4-3 by lower shower net 4-4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com