Heat pipe cold guide device and cold storage body and freezer with said device

A heat pipe and cold storage technology, applied in the field of cold storage, can solve the problems of cold energy loss and low efficiency, and achieve the effects of less cold energy loss, simple structure, and convenient maintenance and control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

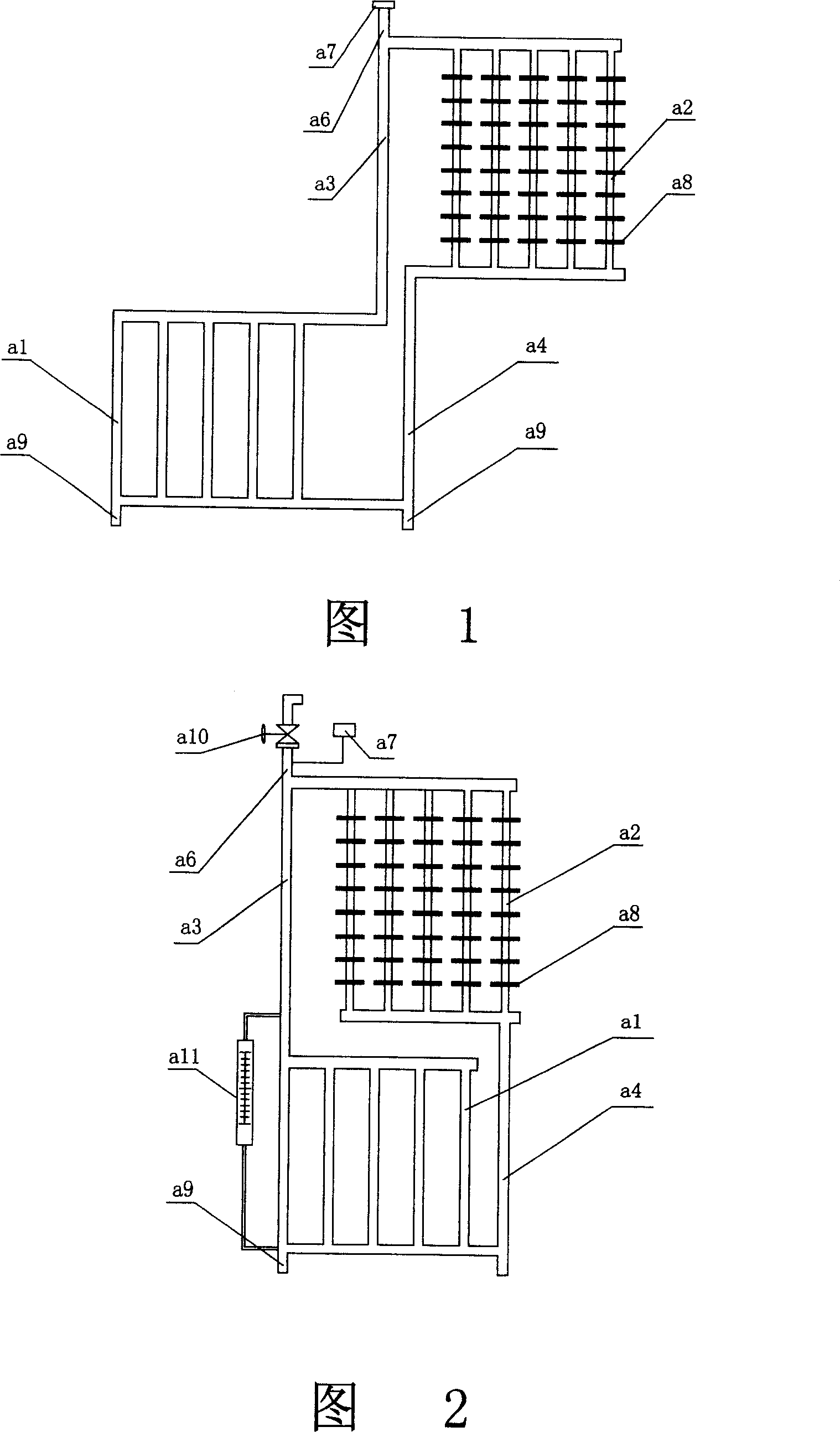

[0035] As shown in Figure 1, it includes the condensing tube group a2 on the upper right and the evaporating tube group a1 on the lower left. The evaporating tube group a1 includes five evaporating tubes, and the condensing tube group a2 includes five condensing tubes. The tubes are respectively connected in parallel through headers, then the upper headers of the evaporating tube group are connected with the upper headers of the condensing tube group through the rising pipe a3, and the lower headers of the evaporating tube group are connected with the lower headers of the condensing tube group through the downcomer a4 , thus forming a gravity heat pipe circulation loop. In order to ensure that the working medium of the condenser tube group a2 flows back smoothly to the evaporation tube group a1, the condenser tube group a2 is higher than the evaporation tube group a1, and the lower header of the condenser tube group a2 is higher than the upper header of the evaporator tube grou...

Embodiment 2

[0040] As shown in Figure 2, compared with Example 1, the condensing tube group a2 is located directly above the evaporating tube group a1, the riser tube a3 is provided with a communication level gauge a11, and the safety valve a7 and switch are provided above the collecting tube a6 valve a10. The on-off valve can be conveniently filled with working fluid, and the on-off valve can be opened to remove impurity gas as required.

Embodiment 3

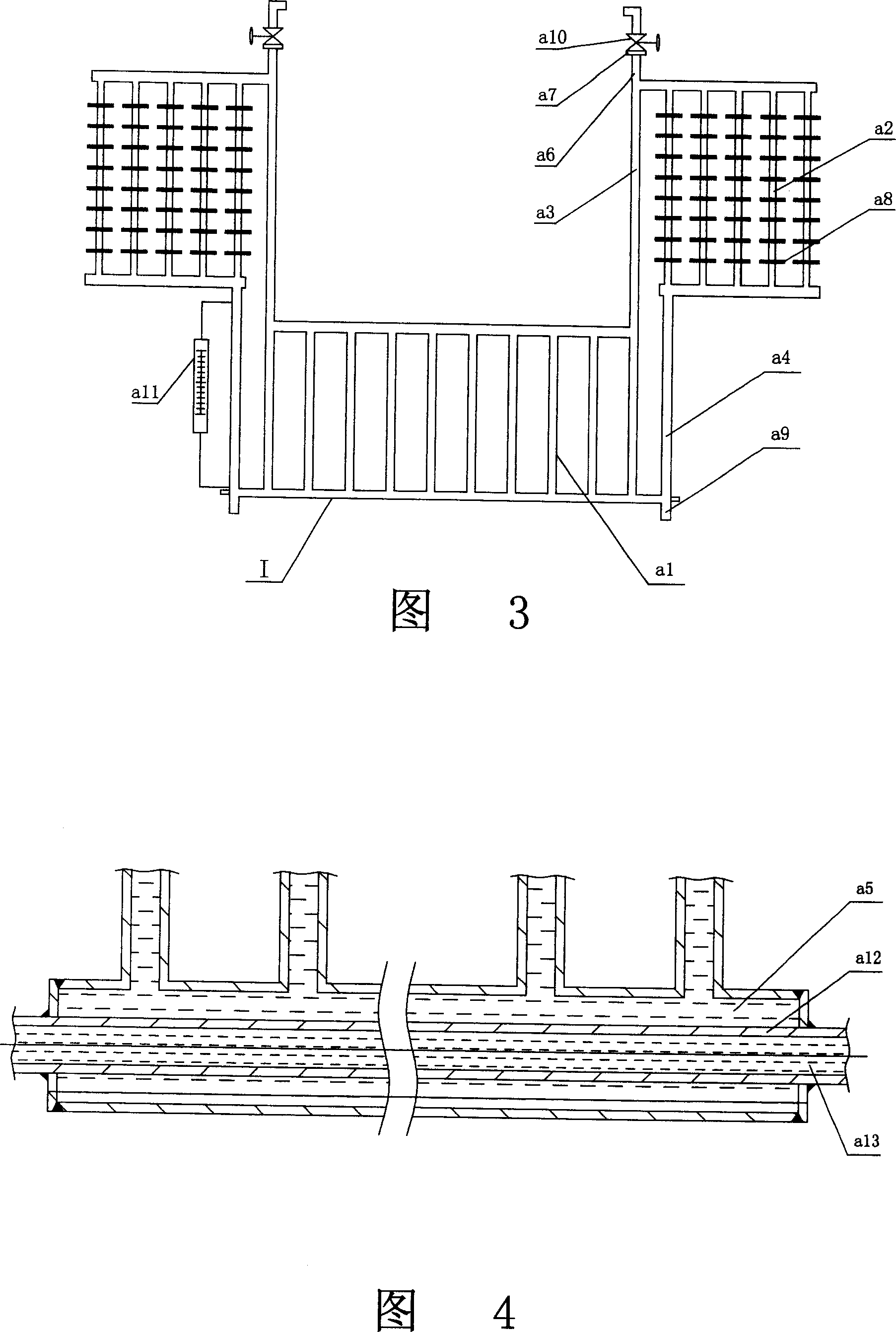

[0042] It is equivalent to the two heat pipes shown in Embodiment 1 being connected and connected symmetrically at the evaporating tube group a1. Moreover, as shown in Figure 4, a cooling circulation pipe a12 is concentrically passed through the lower header of the evaporator group a1, and a circulating working fluid a13 is installed inside. Cooling circulation loop, a pump is set in the cooling circulation loop to take out the cold energy in the cold storage body through circulation, so that the cold energy stored in the cold storage body can be sent to a long-distance space that needs cold energy, and it can also make the cold storage body The circulation pipe is connected in series with the condensation end of the secondary heat pipe to form a heat pipe automatic circulation system, which transports cold energy to the evaporation end of the secondary heat pipe.

[0043] Cold storage body embodiment 1:

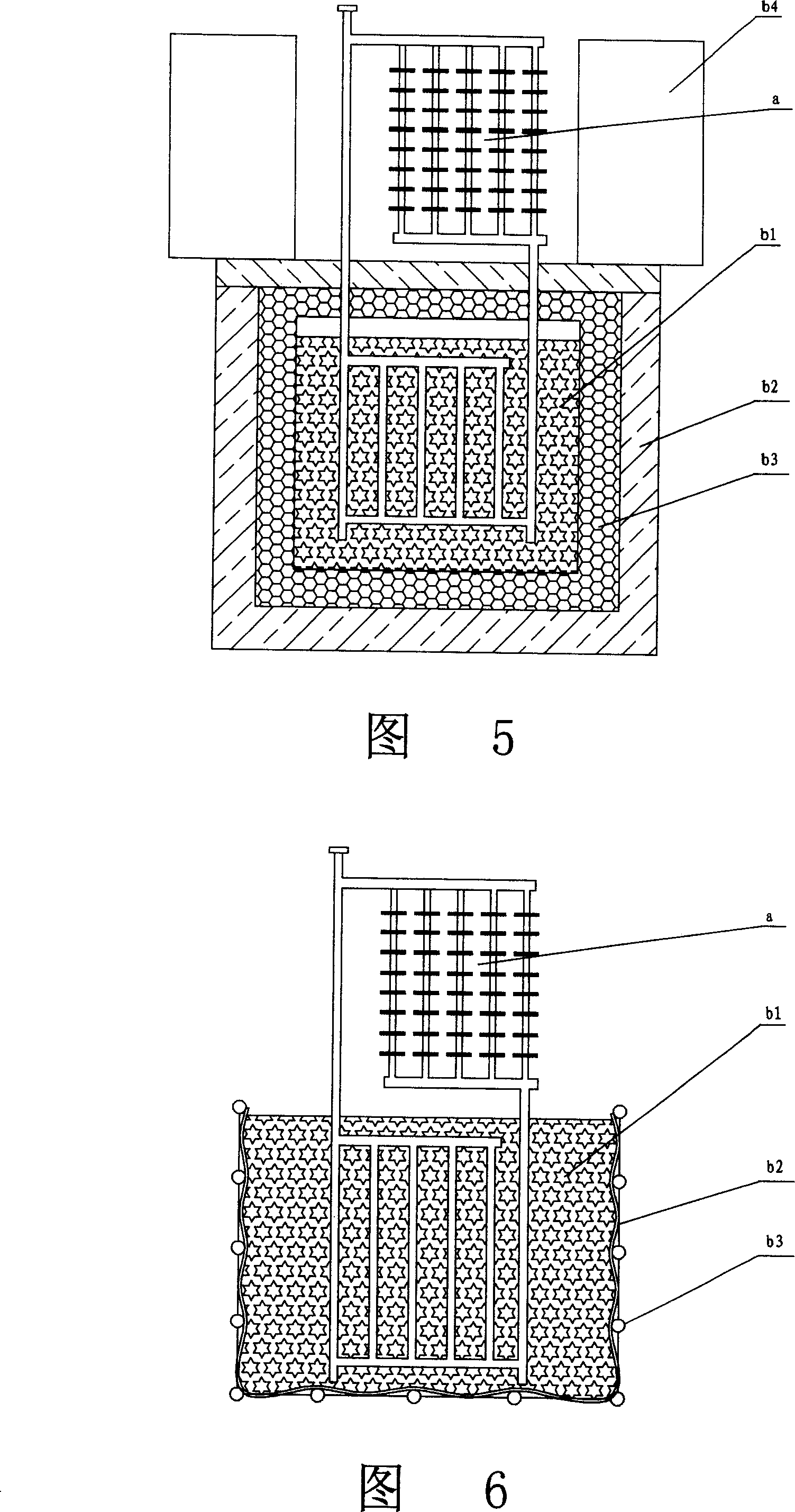

[0044] As shown in Figure 5, it includes a cold storage medium, usuall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com