Air-flow spinner

An air spinning machine and yarn technology, which is applied to spinning machines, open-end spinning machines, continuous winding spinning machines, etc., can solve the problems of complex and expensive design and structure of auxiliary devices, and achieve simple structure, The effect of low cost and low twist coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

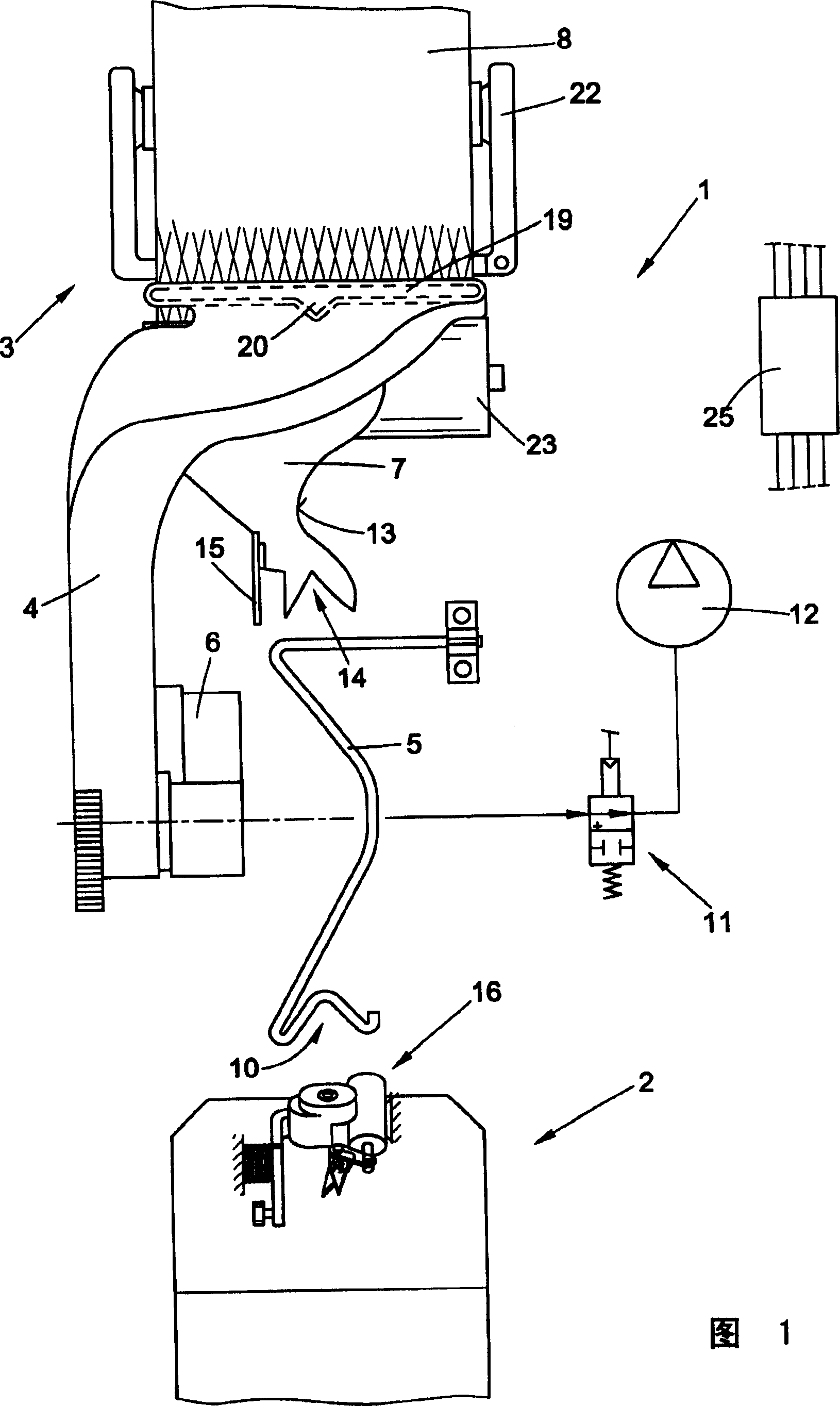

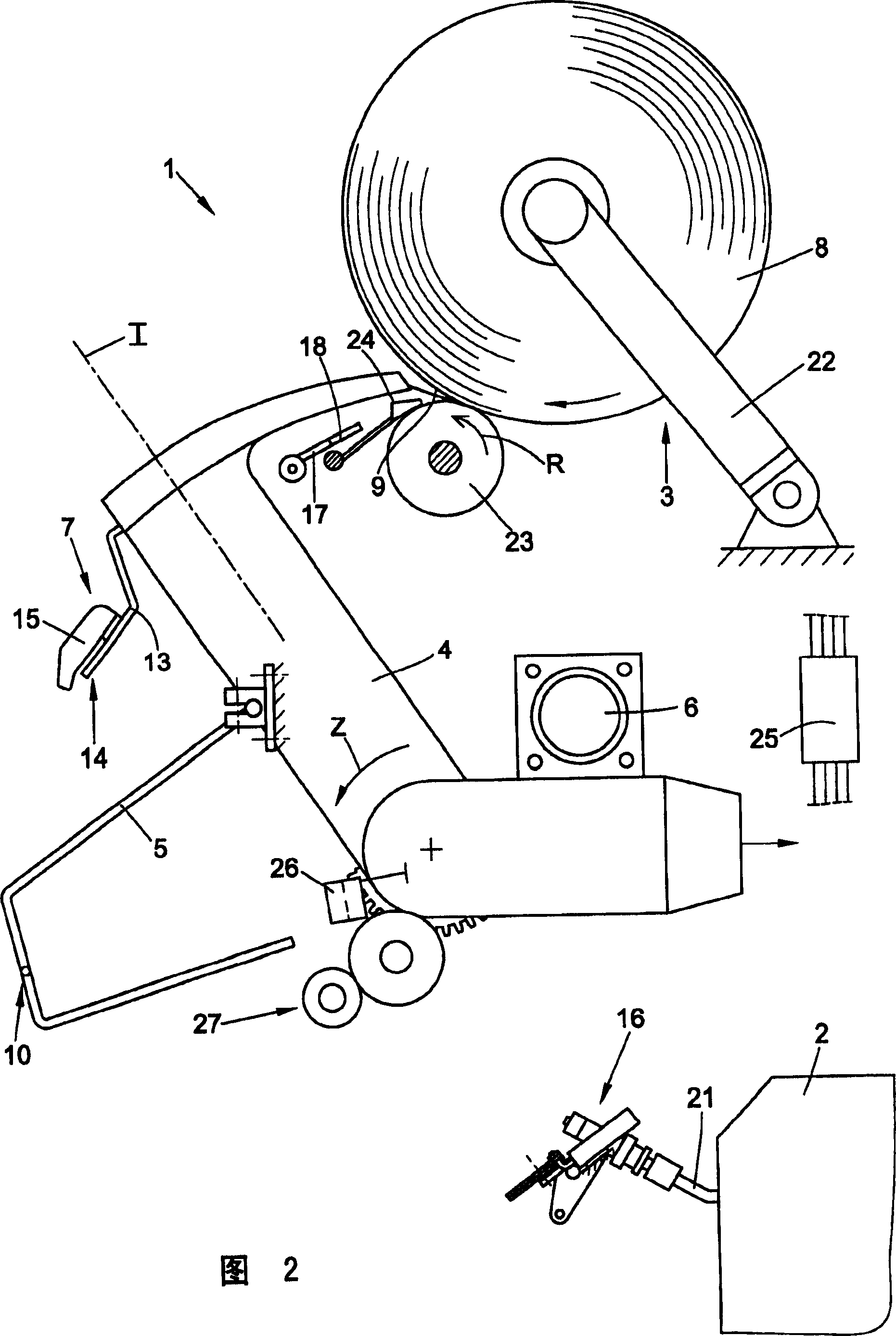

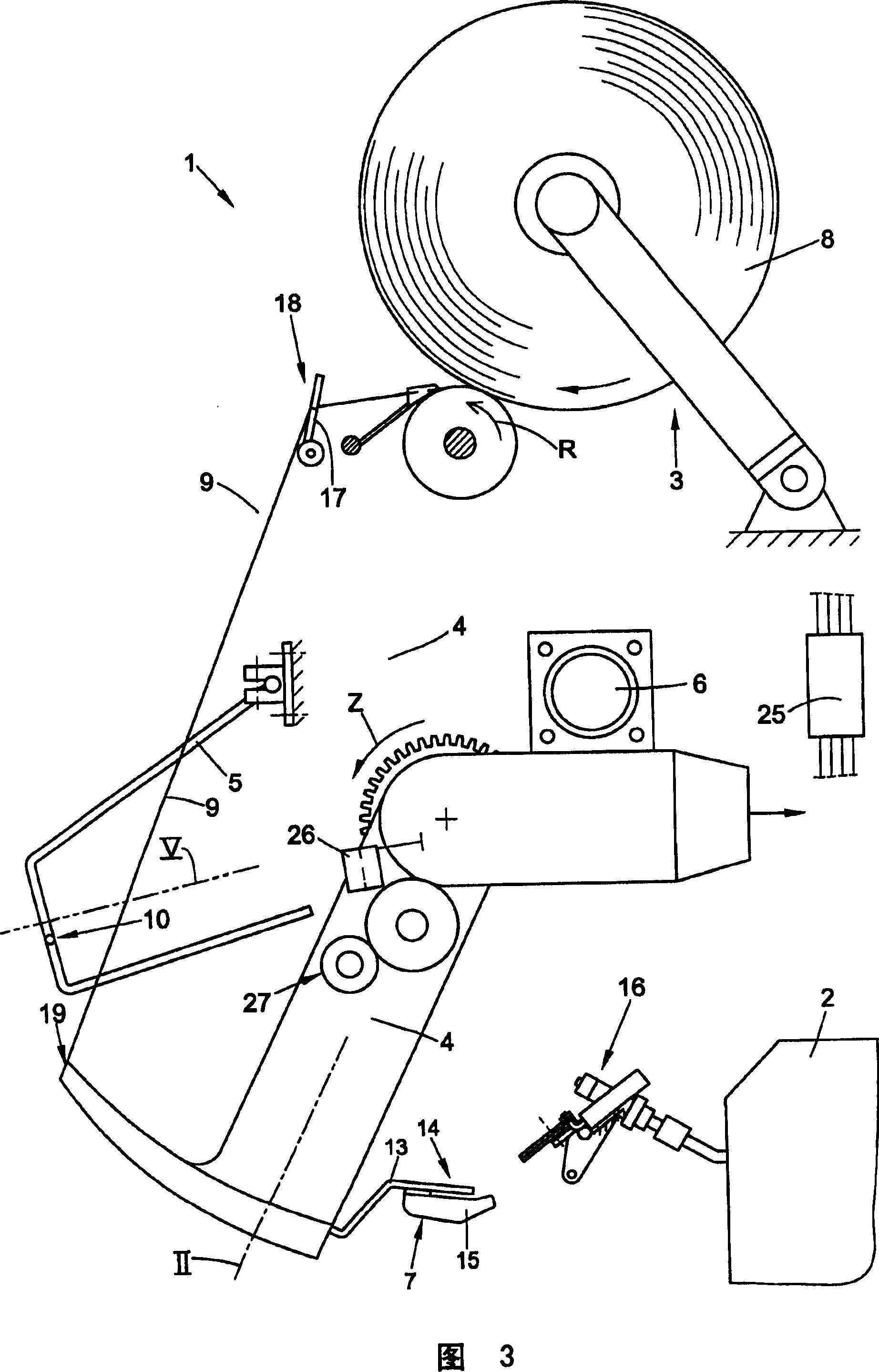

[0032] The working positions of the air spinning machine shown in the front view in FIG. 1 are generally indicated by reference numeral 1 . As shown in the figure, the working positions 1 each have an air spinning device 2 and a winding device 3 which are known per se and are therefore only shown schematically. Furthermore, at each working position 1 there is a piecing mechanism 16 , a yarn breakage detector 26 and a yarn unwinding device 27 . The rotatably mounted piecing mechanism 16 arranged just before the yarn unwinding tube 21 of the air spinning device 2 pre-treats the yarn 9 sucked back by the suction nozzle 4 from the cross-winding bobbin 8, for example after a yarn break, in order to re- connector. Then, the yarn unwinding device 27 returns the prepared yarn 9 to the air spinning device 2 through the yarn unwinding tube 21, where, as known, the yarn is connected to a surrounding fiber loop.

[0033] As usual, the winding device 3 comprises a creel 22 holding a cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com