Microcomputer controlled semi-automatic optical fibre circling machine

A microcomputer-controlled, winding machine technology, applied in the directions of light guides, optics, optical components, etc., can solve problems such as the inability to guarantee winding quality, and achieve the effects of human-computer interaction, low cost, and simple mechanical structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below with reference to the accompanying drawings.

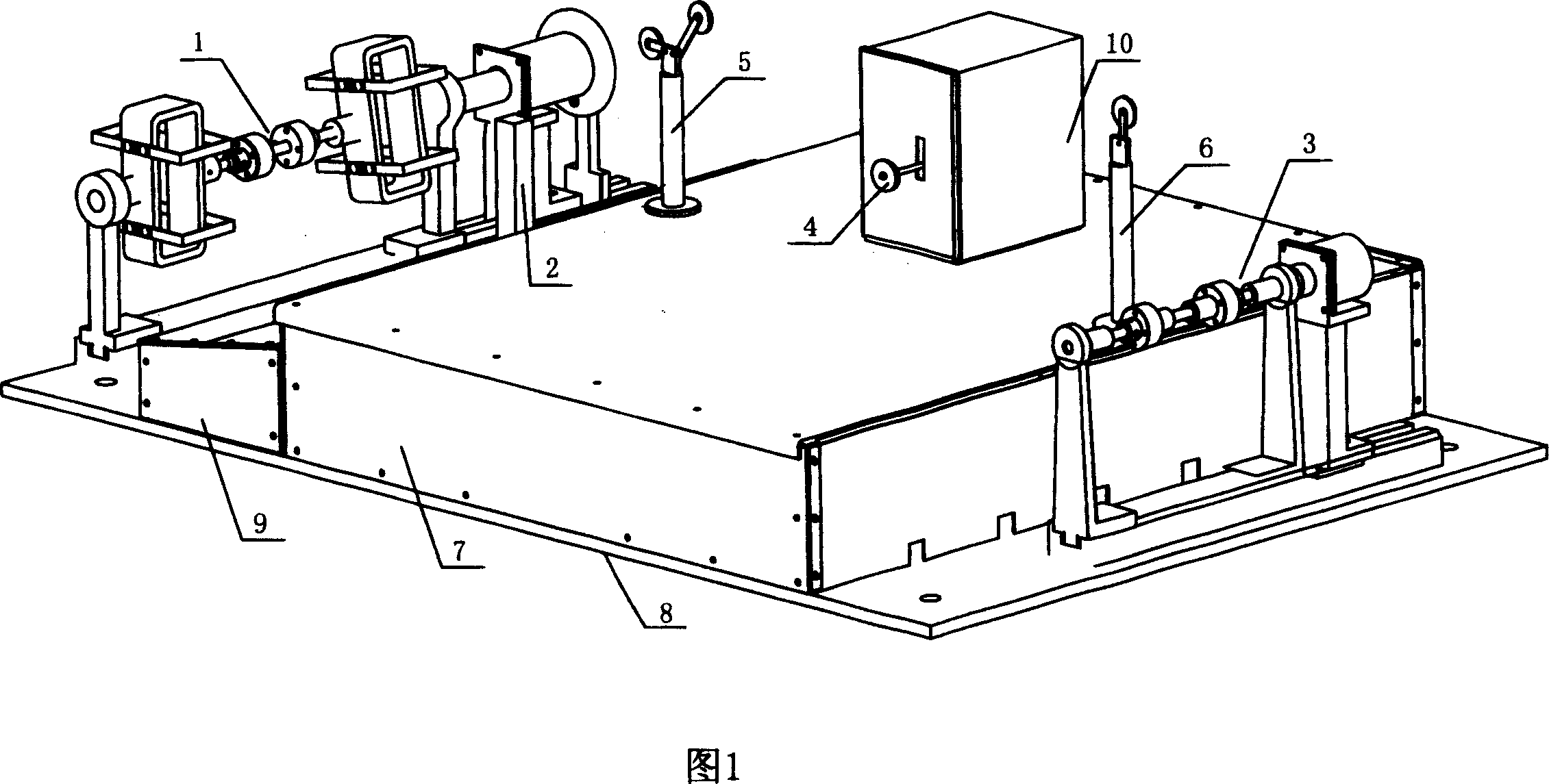

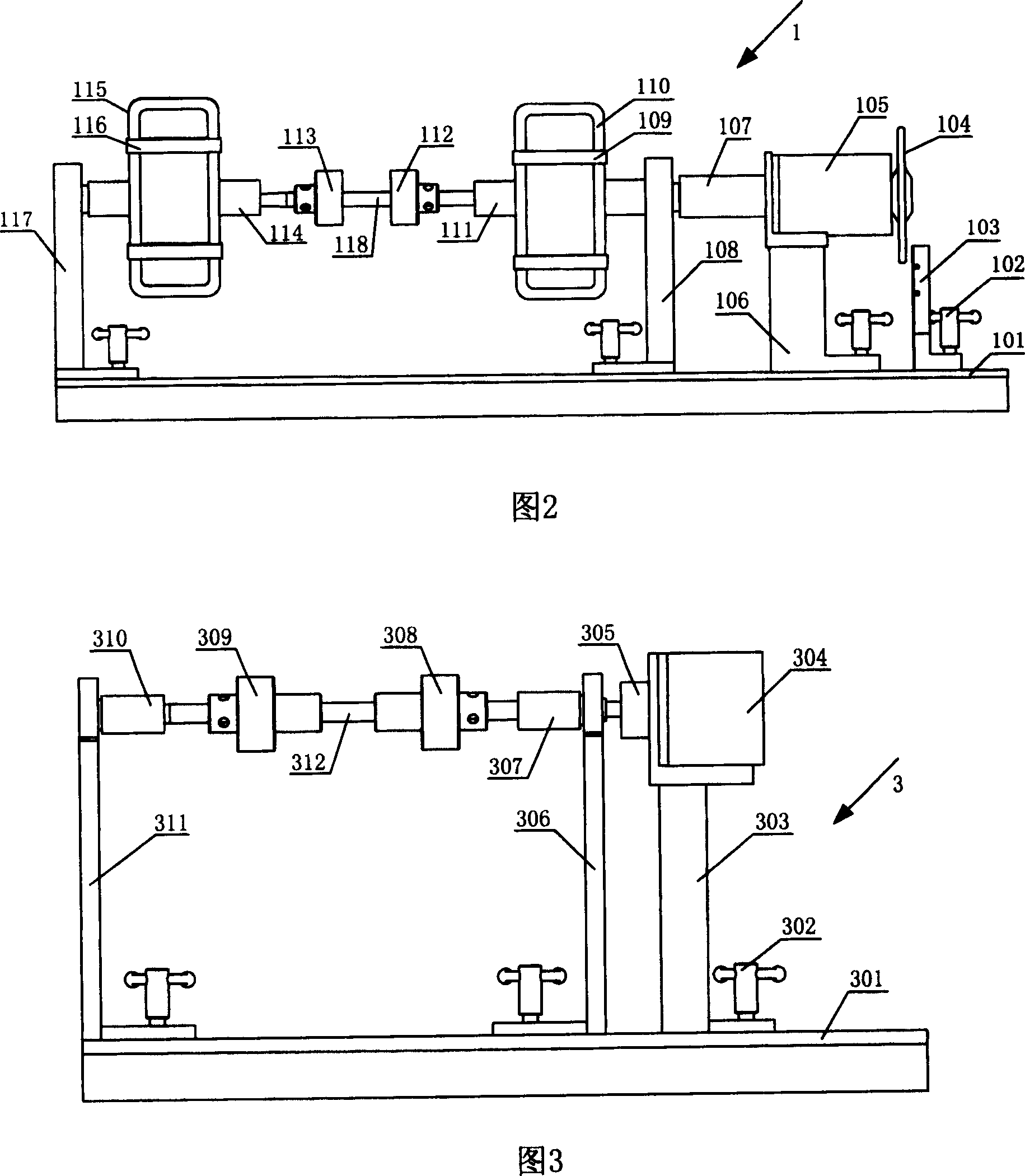

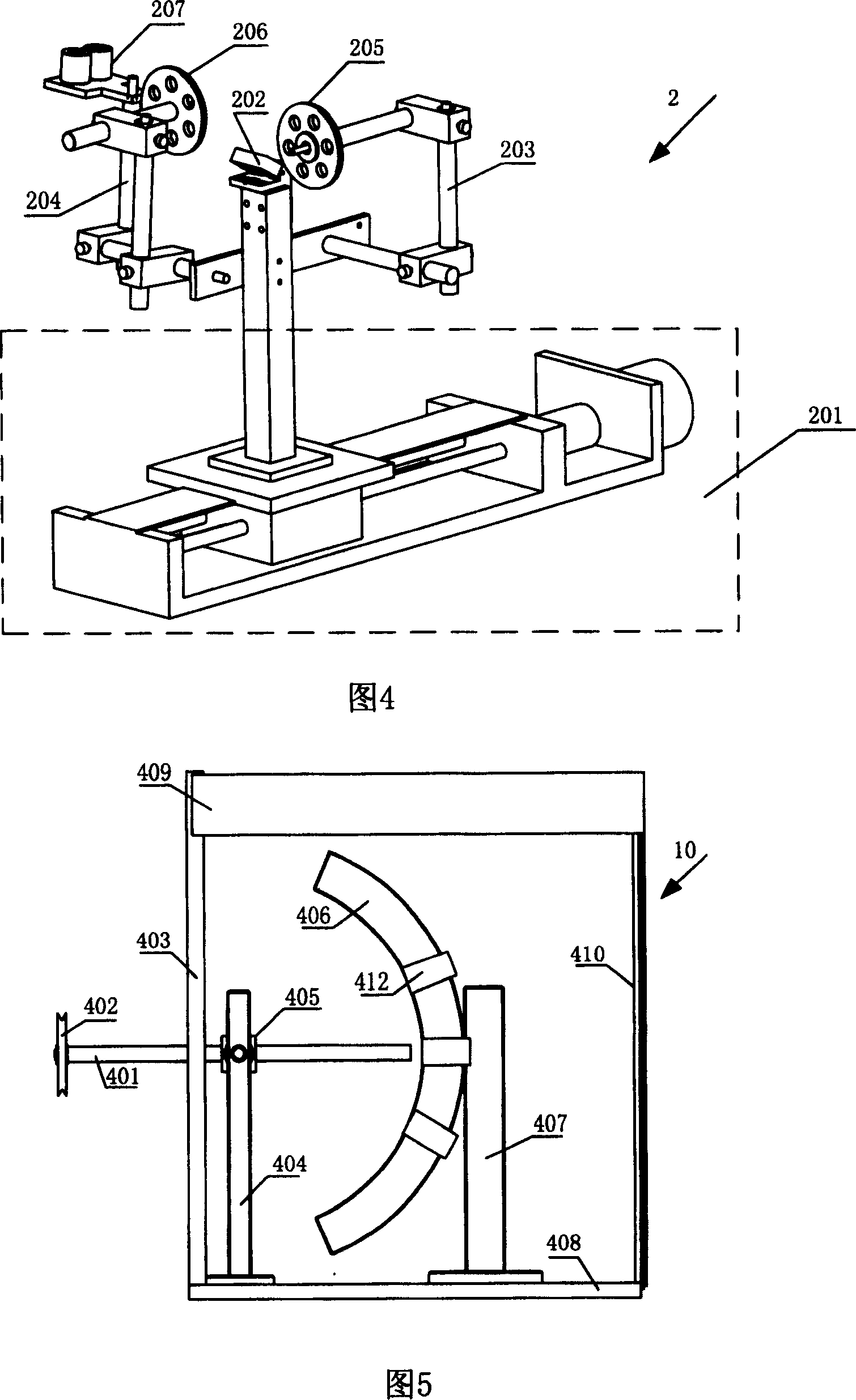

[0032] Please refer to Figures 1 to 5. The present invention is a microcomputer-controlled semi-automatic looping machine, including a PC, a program stored in the PC, and a looping machine. The looping machine is composed of a fiber supply mechanism 3, Fiber arranging mechanism 2, fiber collecting mechanism 1, tension control mechanism 4, chassis 8, box body 7 and winding electrical control system. In order to facilitate smooth fiber winding, a magnetic bracket can also be fixed on box body 7. The position is on the same axis as the tension control dancer 402 of the tension control mechanism 4 . The fiber supply mechanism 3, the fiber discharge mechanism 2, and the fiber collection mechanism 1 are installed on the chassis 8, and the tension control mechanism 4 is installed in the tension control box 10. The tension control box 10 is fixed on the box body 7 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com