Abrading type oil and water separator for crude oil

A technology of oil-water separator and grinder, which is applied in liquid separation, separation method, immiscible liquid separation, etc., can solve problems such as unsatisfactory dehydration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

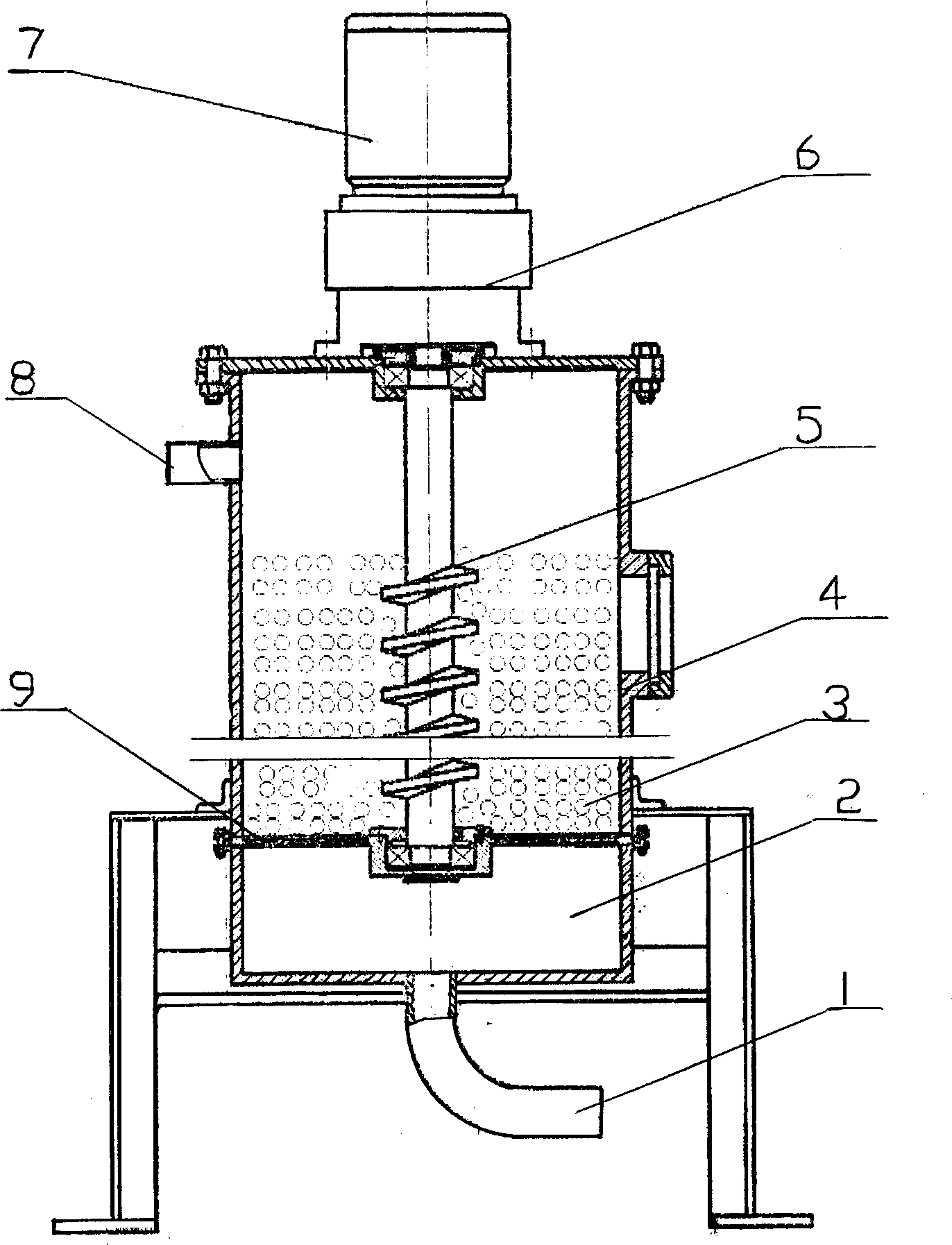

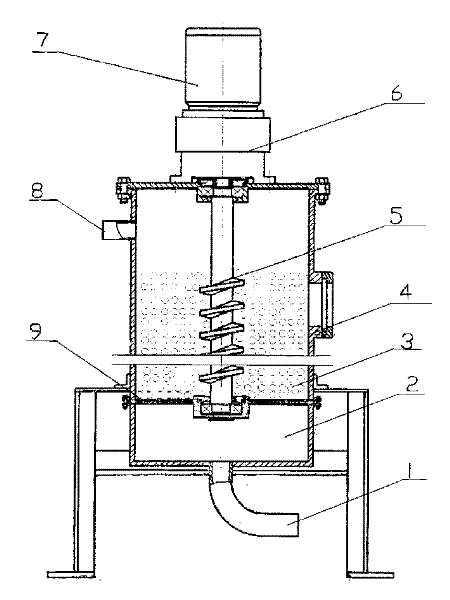

[0012] see figure 1 , the present invention includes a mixed liquid inlet 1, which is welded together with the lower box body 2, and the lower box body 2 is connected with the grinder body 4 with bolts, and between the lower box body 2 and the grinder body 4 is a bolt The compressed porous plate 9 is also equipped with a vertical screw shaft 5 and stacked grinding balls 3 in the grinder body 4. The lower end of the screw shaft 5 is mounted on the bearing seat of the porous plate 9, and the upper end is mounted on the grinder body. On the upper cover bearing seat of 4, the upper end side of the body grinder is also welded with an oil-water liquid outlet 8, and the motor 7 on the top is connected with the upper end of the screw shaft 5 through the speed changer 6.

[0013] Working principle of the present invention is: as attached figure 1 As shown, after the mixed liquid extracted from the oil well enters the grinder body 4 through the mixed liquid inlet 1 and the porous plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com