Connection structure for display module and printed base plate and semiconductor device, display module and electronic member

A technology for printed substrates and display modules, applied in the directions of printed circuit components, structural connection of printed circuits, printed circuits, etc., can solve problems such as unfavorable thin installation, and achieve stable conduction and reliable contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

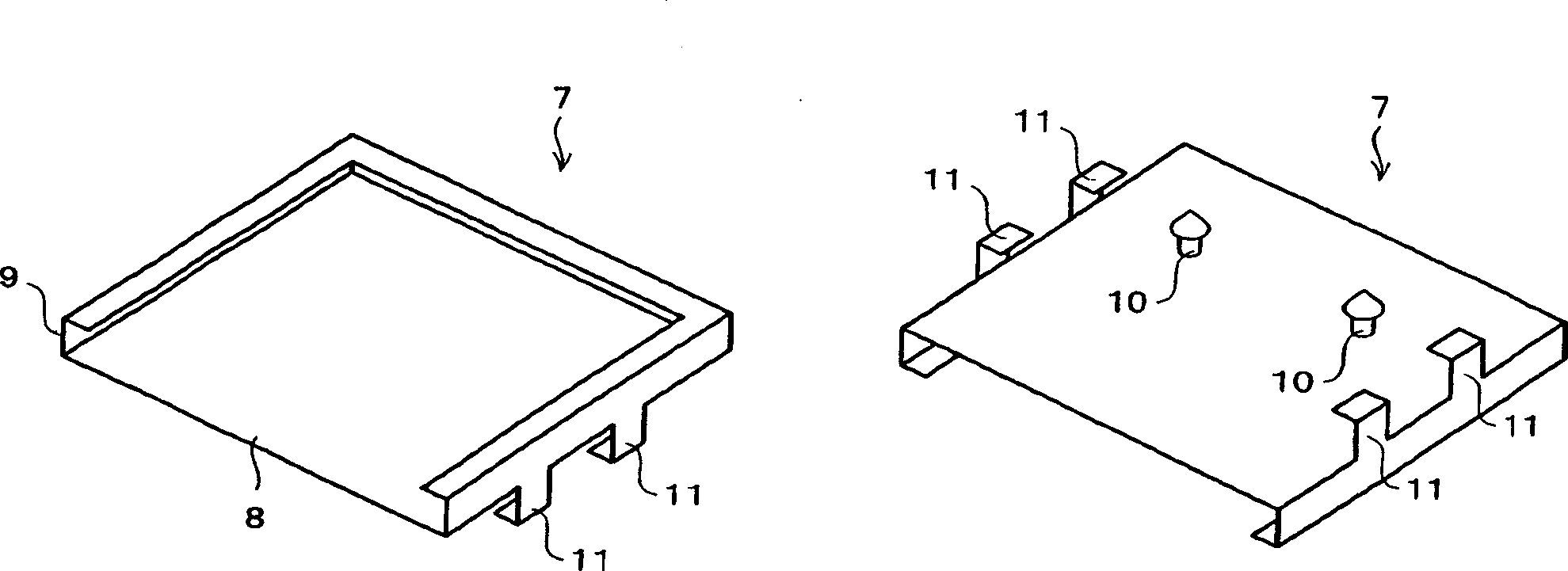

[0053] Hereinafter, an embodiment of a connection structure between a display module and a printed circuit board, a semiconductor device, a display module, and electronic components of the present invention will be described.

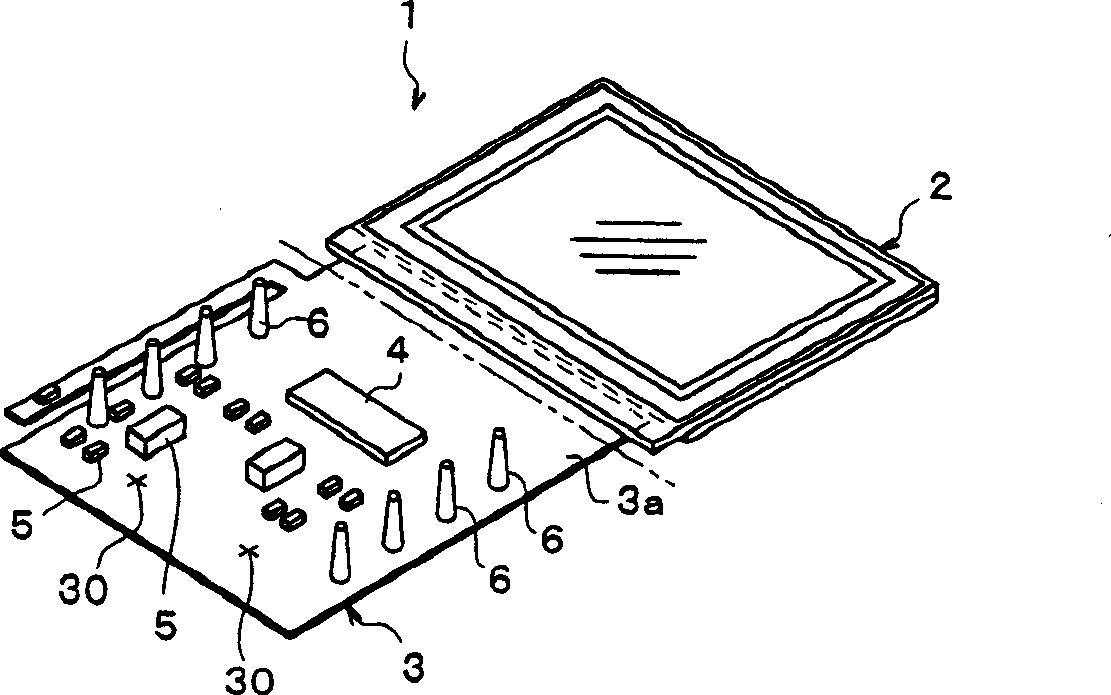

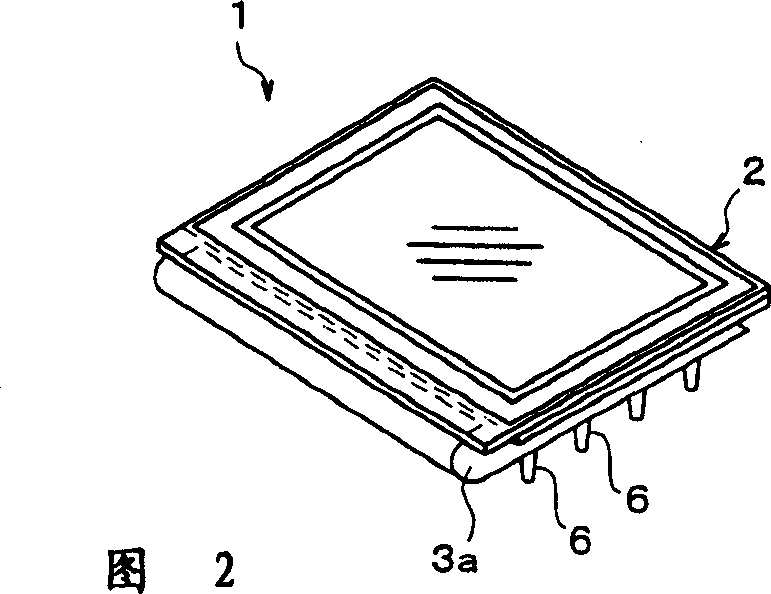

[0054] exist figure 1 2 shows a liquid crystal module (display module) 1 in which a liquid crystal panel (display panel) 2 and a COF 3 serving as a liquid crystal driver (semiconductor device) are connected. A semiconductor element 4 constituting a liquid crystal driver IC and a plurality of mounting components 5 .

[0055] Furthermore, in this COF 3 , conventionally, planar electrodes are formed on the external connection terminals. In addition, the so-called external connection terminals are terminals for connecting the wiring formed on the flexible wiring board 3a and the electrodes of the printed board described later.

[0056] On the other hand, in this embodiment, pin-shaped pin electrodes (protrusion-shaped electrodes) 6 . . . formed of a cond...

Embodiment 2

[0075] Below, use Figure 6 and Figure 7 , illustrating another embodiment of the connection structure between the display module and the printed substrate, the semiconductor device, the display module, and the electronic component of the present invention. In addition, for the convenience of description, the components having the same functions as those shown in the drawings of the first embodiment are given the same reference numerals, and their descriptions are omitted.

[0076] Figure 6 A liquid crystal module (display module) 20 in this embodiment is shown in . The liquid crystal module 20 has COF21 instead of COF3 in the structure of the liquid crystal module 1. In addition, COF21 has bump electrode 22... instead of pin electrode 6... in the structure of COF3.

[0077] That is, the semiconductor element 4 and the plurality of mounting parts 5 constituting the liquid crystal driver IC are mounted on the flexible wiring substrate 3a as the base of the COF 21. In this r...

Embodiment 3

[0083] Below, use Figure 8 , to describe another embodiment of the connection structure between the display module and the printed substrate, the semiconductor device, the display module, and the electronic components of the present invention. In addition, for the convenience of description, the components having the same functions as those shown in the drawings of the first embodiment are given the same reference numerals, and their descriptions are omitted.

[0084] Figure 8 A liquid crystal module (display module) 25 in this embodiment is shown in . The liquid crystal module 25 has COF26 instead of COF3 in the structure of the liquid crystal module 1. Moreover, COF26 has the spring electrode 27 instead of the pin electrode 6... in the structure of COF3.

[0085] That is, the semiconductor element 4 and the plurality of mounting parts 5 constituting the liquid crystal driver IC are mounted on the flexible wiring substrate 3a as the base of the COF 26. In this regard, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com