Roller for continuous measuring stress distribution applied on strip

A technology for stress distribution and measuring rollers, applied in tension measurement, measuring device, electromagnetic measuring device, etc., can solve the problems of long time, complicated operation and expensive removal of guide rollers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

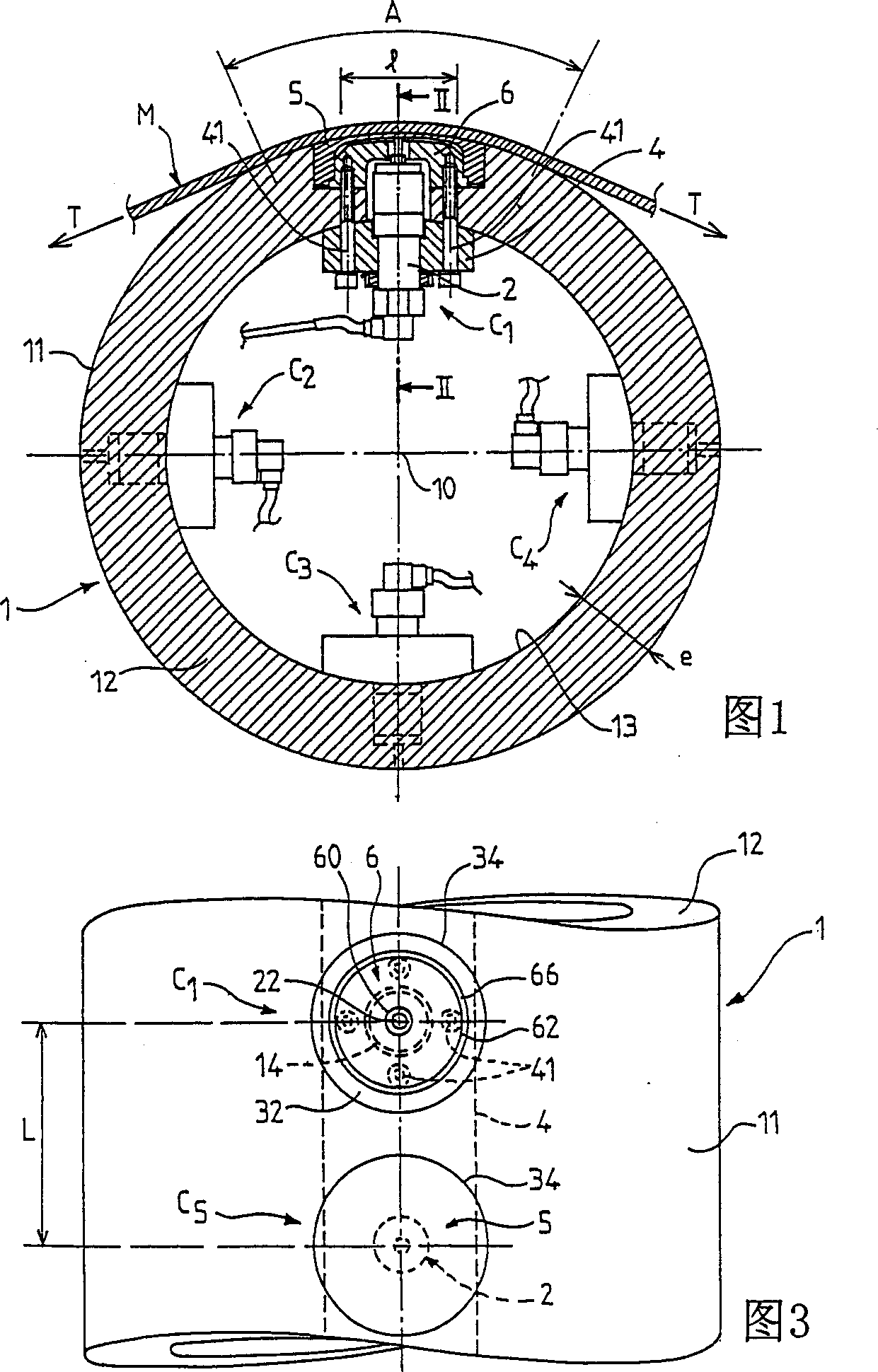

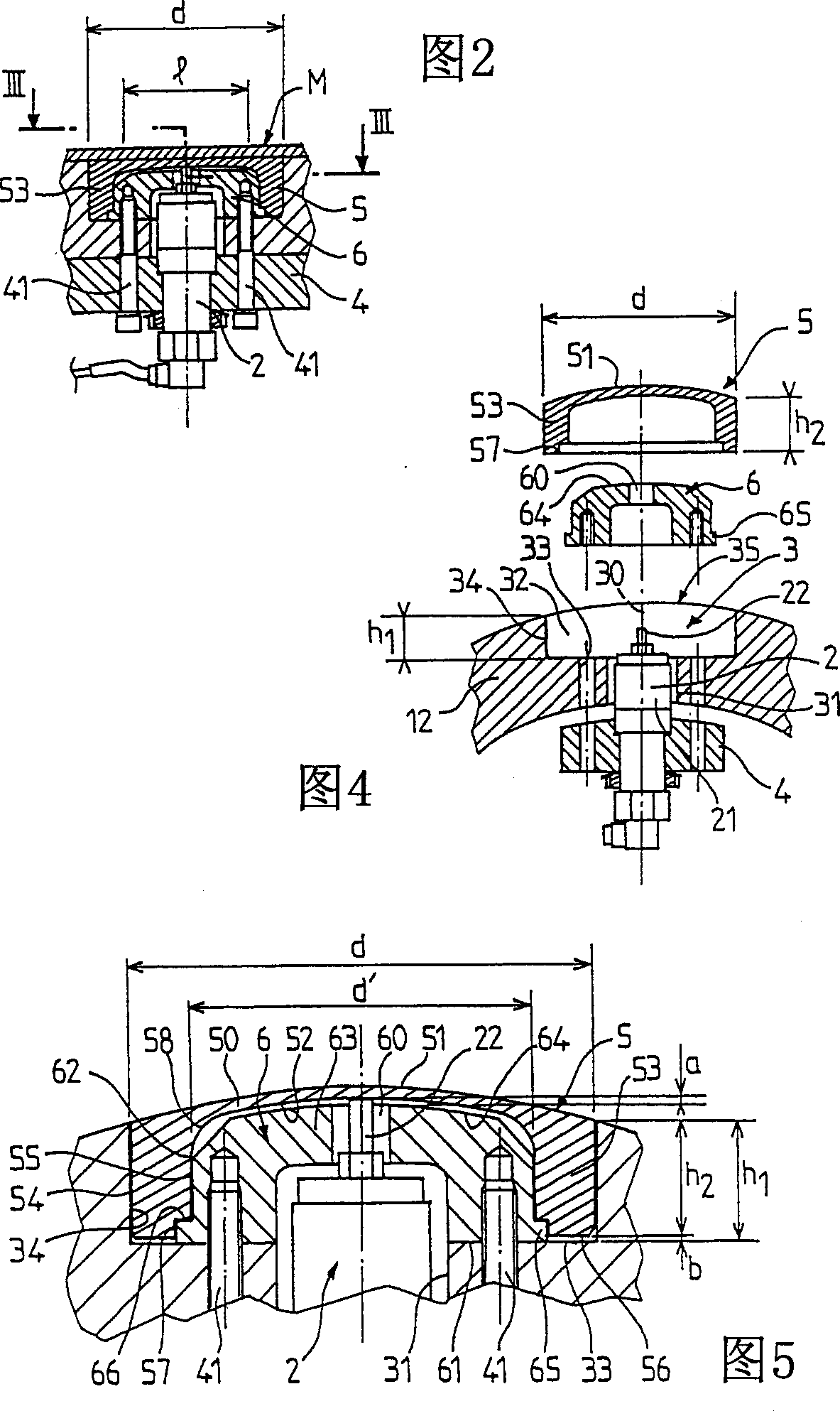

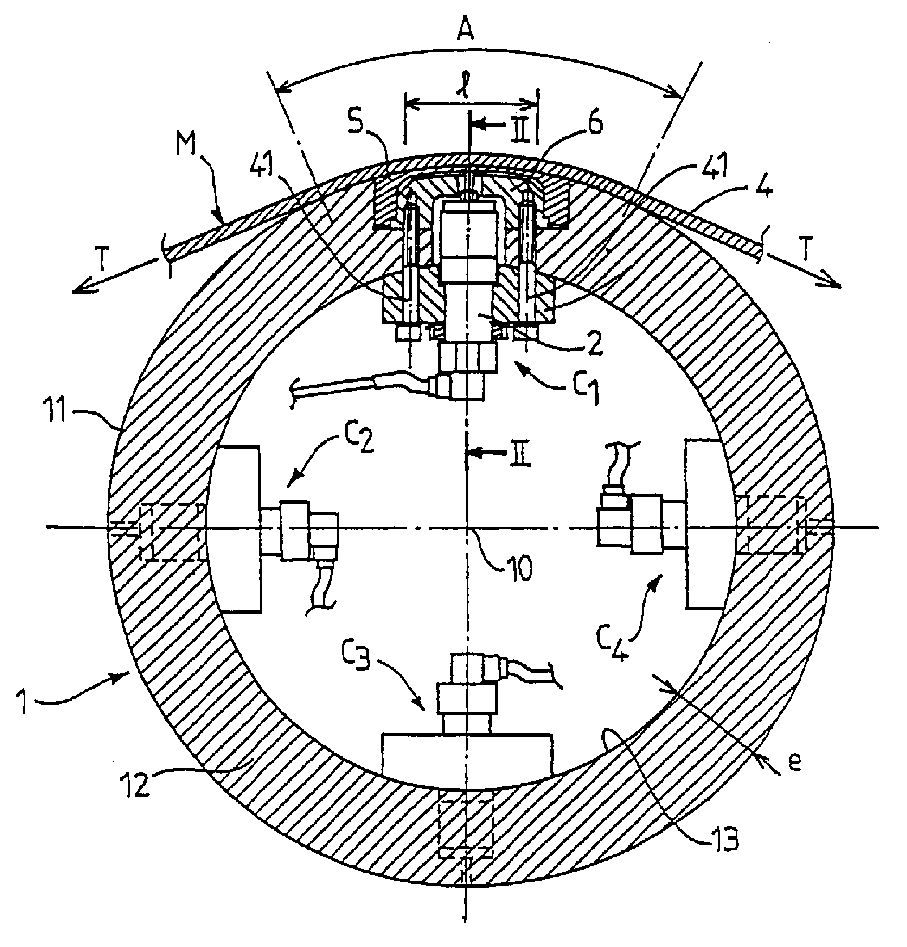

[0041] Figure 1 shows a cross-sectional view of a flatness measuring roll 1, which generally consists of a metal strip (M) running longitudinally perpendicular to the axis of rotation 10 of the roll and wound around the roll The guide rollers on the triangular sector constitute.

[0042] Said strip (M) maintains a tensile stress and therefore acts on the outer surface of the roller 1 under a pressure given by the following formula:

[0043] (2)p=T / R

[0044] where (T) is the tensile stress load per unit bandwidth and (R) is the radius of the outer surface of the roll.

[0045] The guide rollers according to the invention are of the type with displacement sensors as described in the European patent EP-0.028.191 of the same company. It is therefore equipped with several sensors spaced laterally at specific angles from one another. As described in the aforementioned patent EP-0.028.191, the different sensors are advantageously distributed on a helical curve wound on the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com