Workpiece handling robot

A technology for robots and workpieces, applied in the field of robotics, can solve the problems of impossible to change or scale the overall size of the robot, limitations, expensive manufacturing, etc., to achieve the effect of easy construction and maintenance, simple structure, strong maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

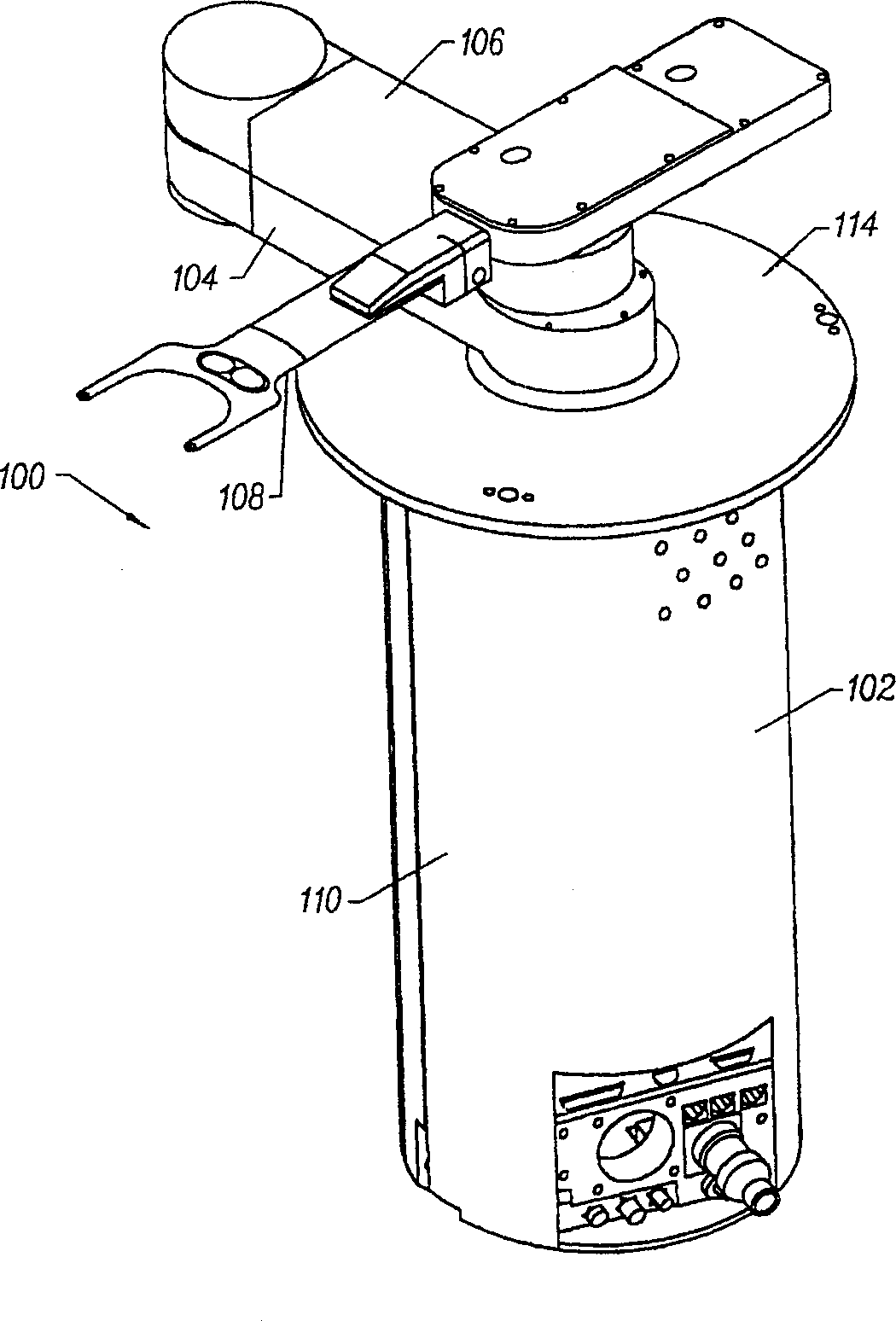

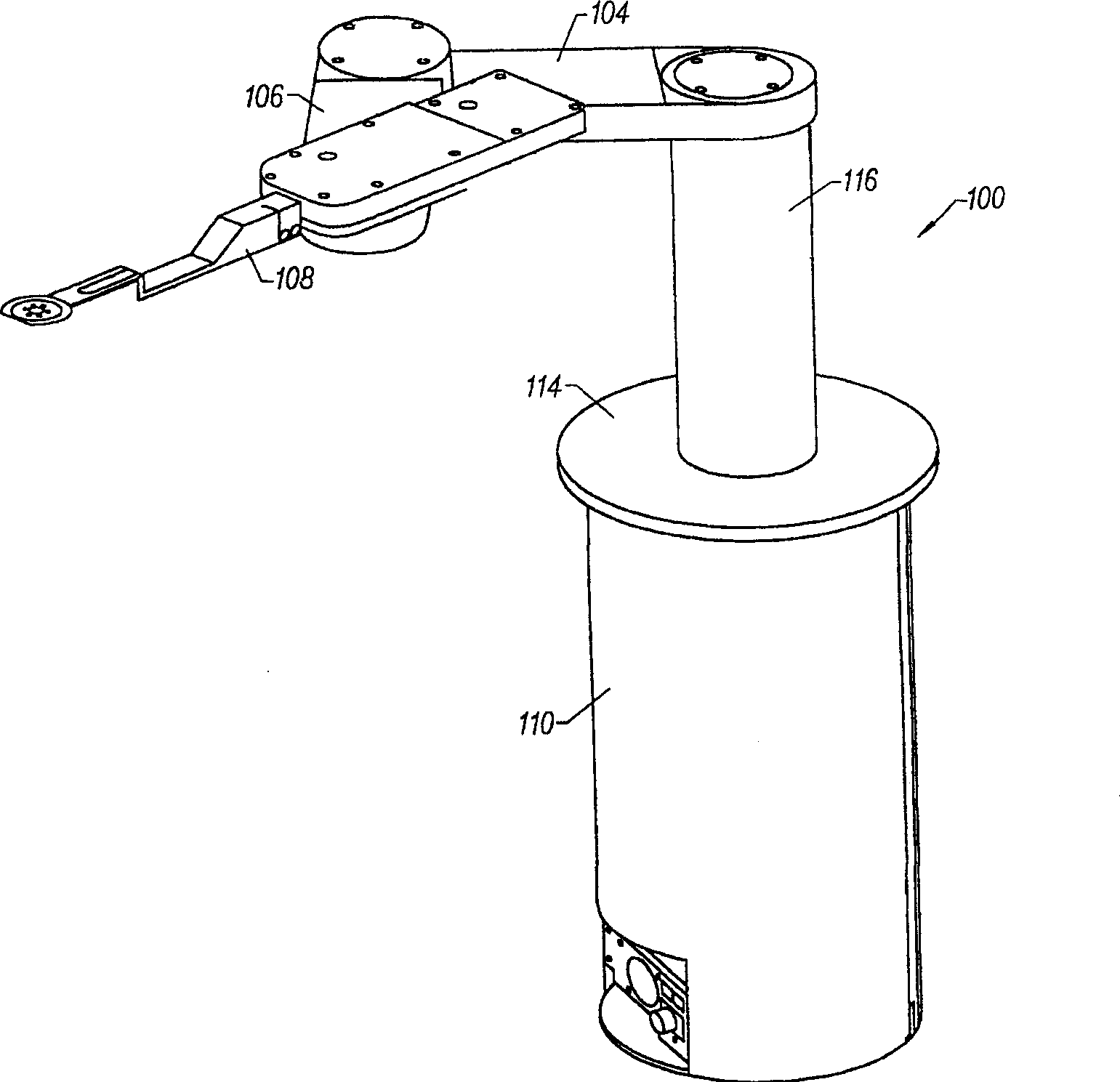

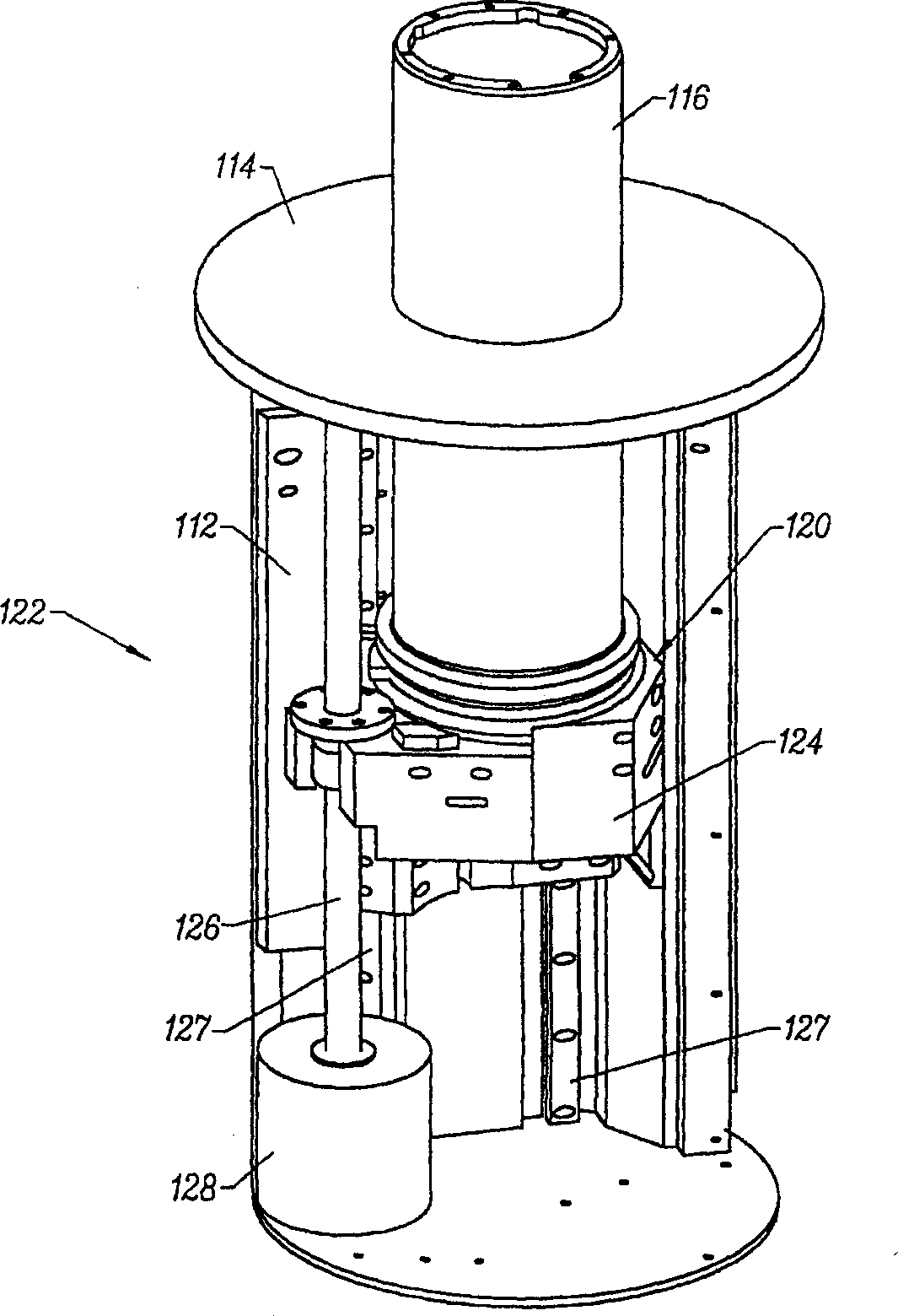

[0036] Now, referring to the attached Picture 1-1 5 describes the present invention, which generally relates to a workpiece handling robot for transferring workpieces between a plurality of processing tools or a processing tool and a workpiece storage location. It should be understood that the workpiece to be conveyed by the present invention may consist of a variety of flat, planar objects including semiconductor wafers, differentiation plates, or flat panel displays. Alternatively, the workpiece to be transported may include a container for storing and transporting one or more wafers, differentiation plates, or flat panel displays. Robots according to the present invention may operate at various locations within a wafer fab, such as within a process tool front end microenvironment, or as part of an assembly for transferring workpieces to or between multiple process tools. part. Furthermore, as will be described in detail below, the present invention is adapted to function...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com