Device for opening and distributing a bundle of filaments when producing a nonwoven textile web

A non-woven fiber web and production process technology, applied in the field of filament devices and non-woven fiber webs, can solve the problems of slowing down, the solution is not completely satisfactory, and the effect is limited.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

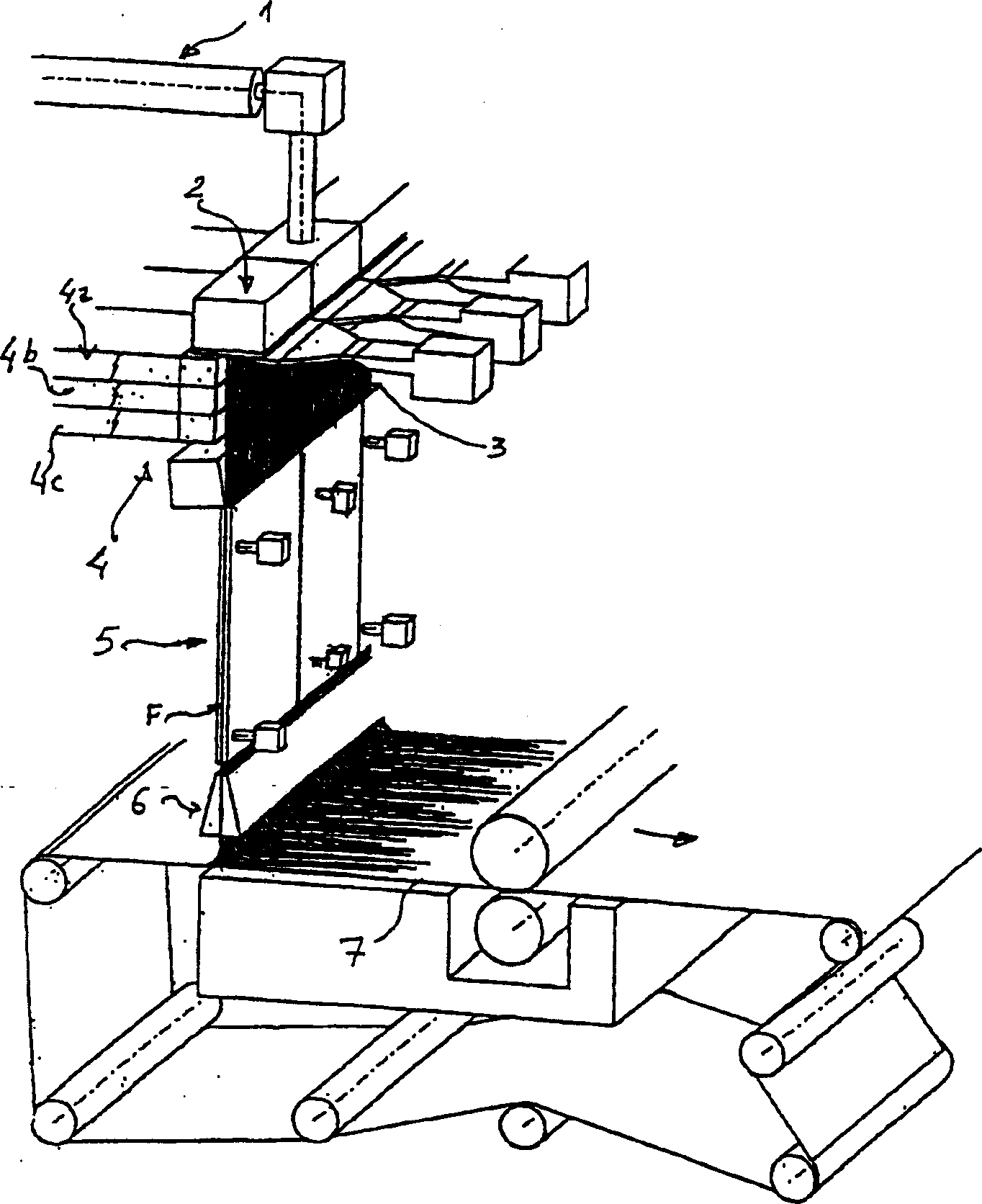

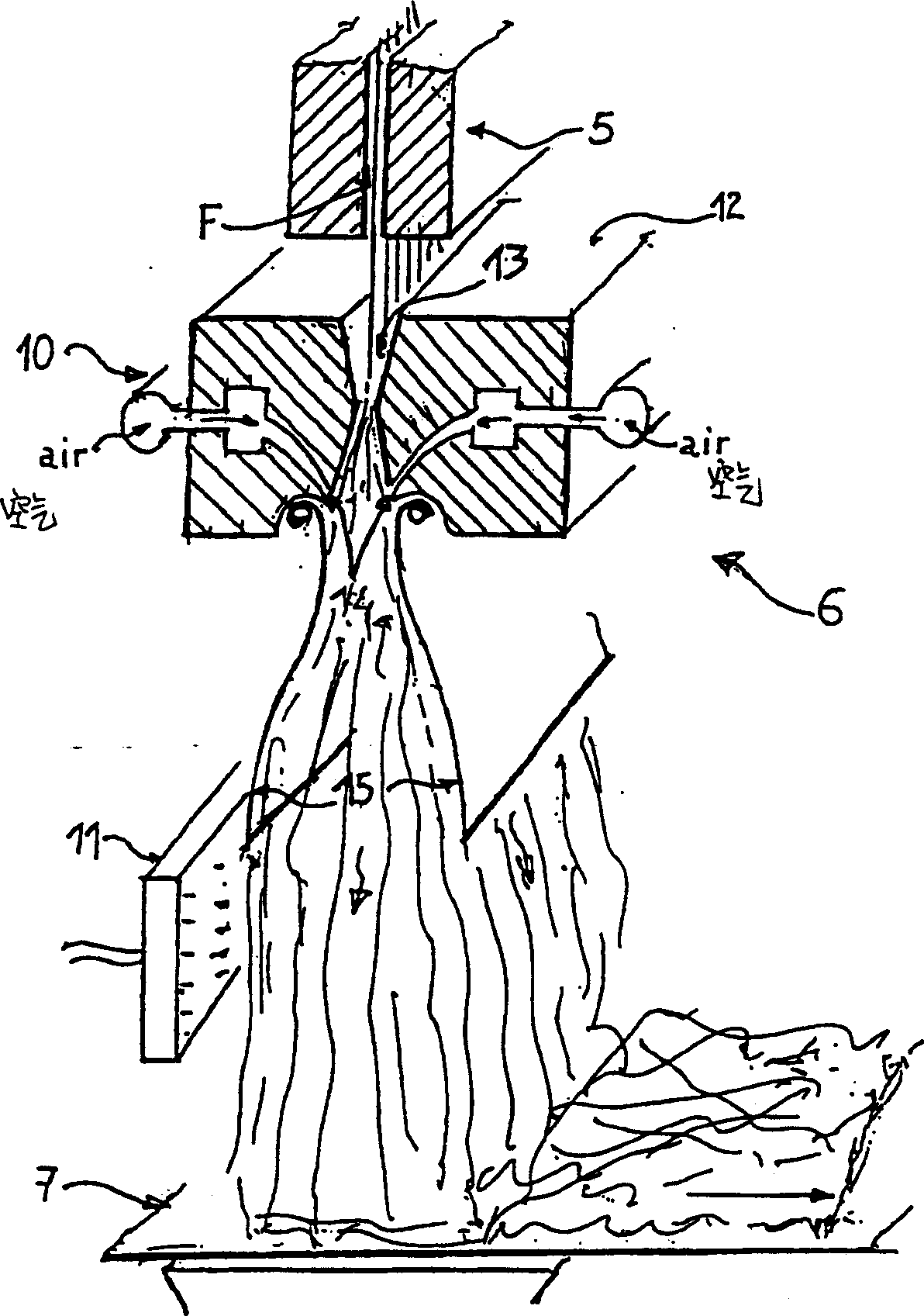

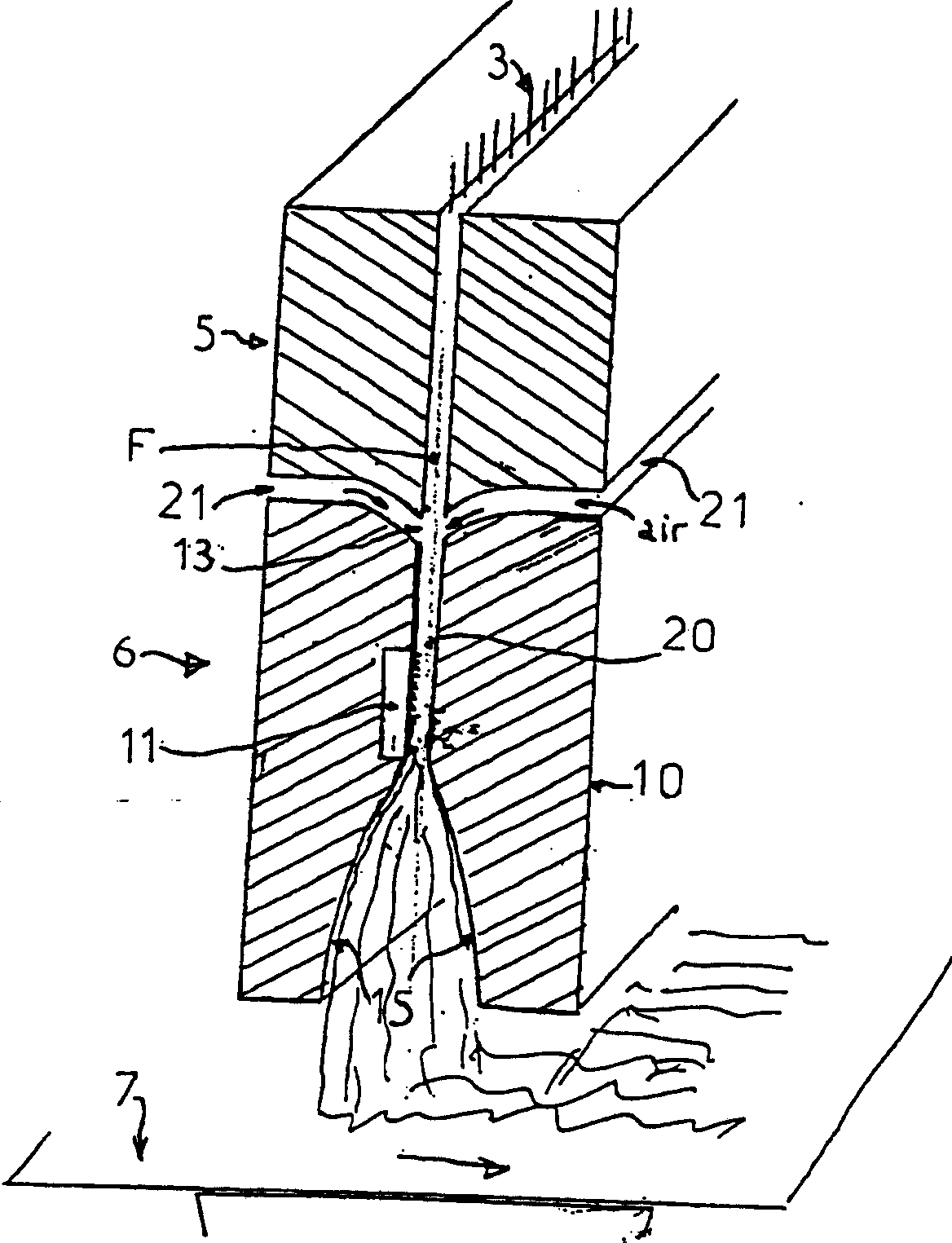

[0044] With reference to the accompanying drawings, the device of the invention is intended for use on a production line for the production of nonwoven webs composed of continuous synthetic filaments.

[0045] Generally speaking, from figure 1 It is seen that such a mechanical structure includes at least one extruder indicated by reference numeral 1, which is used to send synthetic polymers, such as polyamide, polyethylene, polyester, etc., to a machine for forming a row of long filaments 3 Spinneret 2.

[0046] As a guide, from a specific point of view, the spinneret consists of a flat plate containing many holes, for example 5000 per meter width, and the diameter of the holes depends on the extruded filament, for example 0.5 mm, these holes Distributed in several parallel rows, for example 18 rows and over a spinneret outlet with a width of 140 mm.

[0047] At the outlet of this spinneret there is arranged a cooling assembly 4 for adjusting the temperature of the filaments...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com