Liquid crystal display device

A liquid crystal display and device technology, applied in the field of so-called partially transmissive active matrix liquid crystal display devices, can solve problems such as insufficient efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

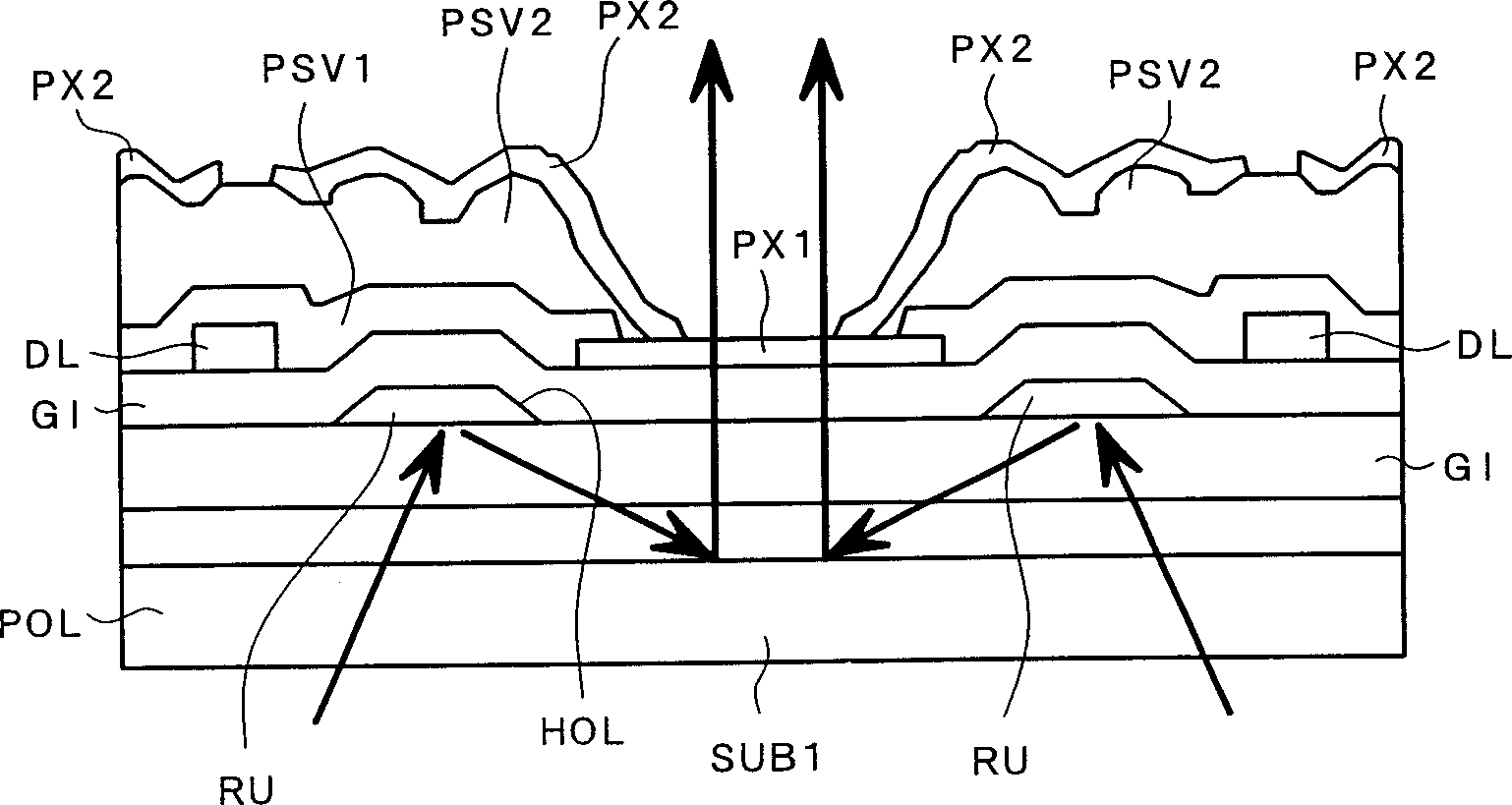

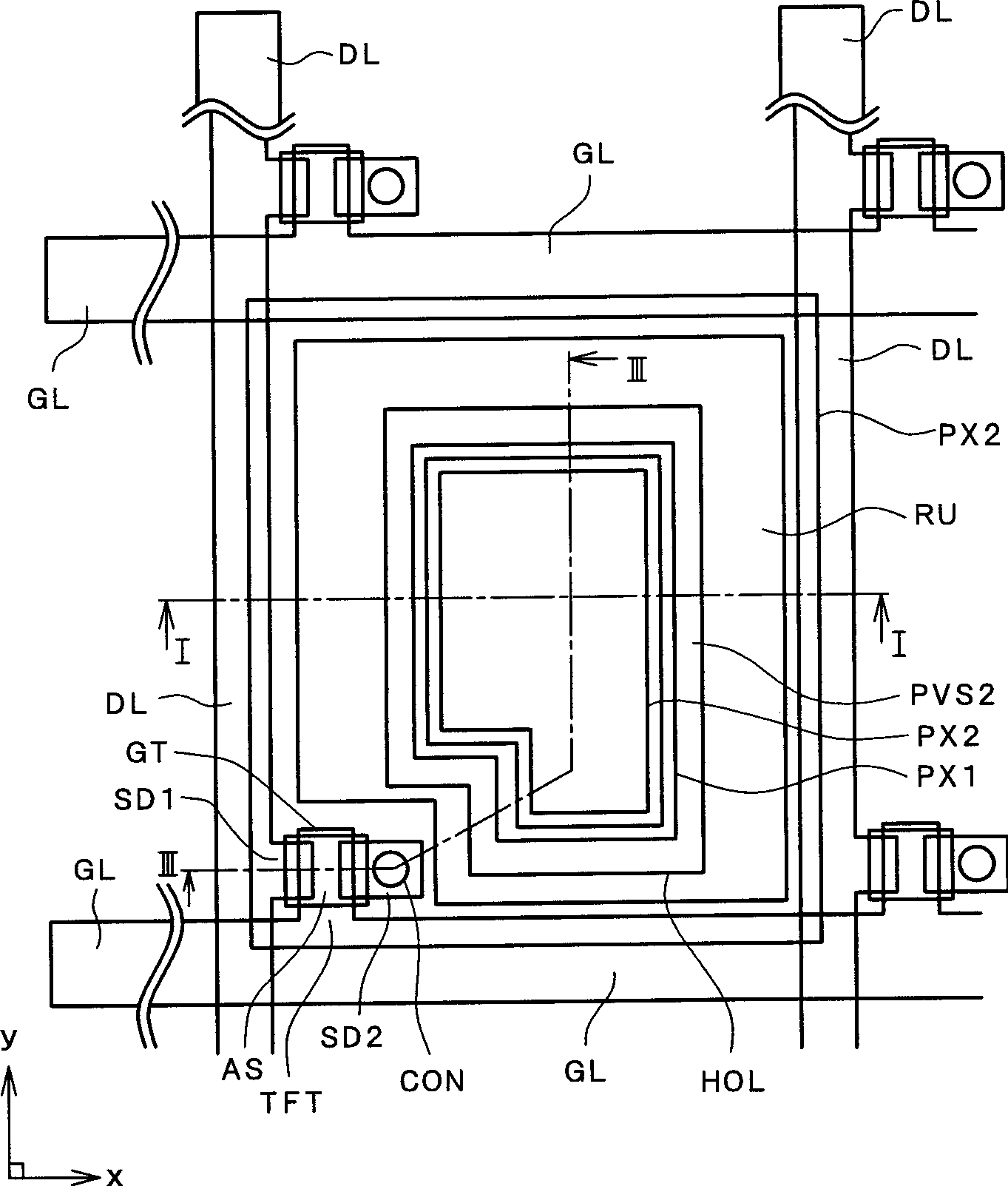

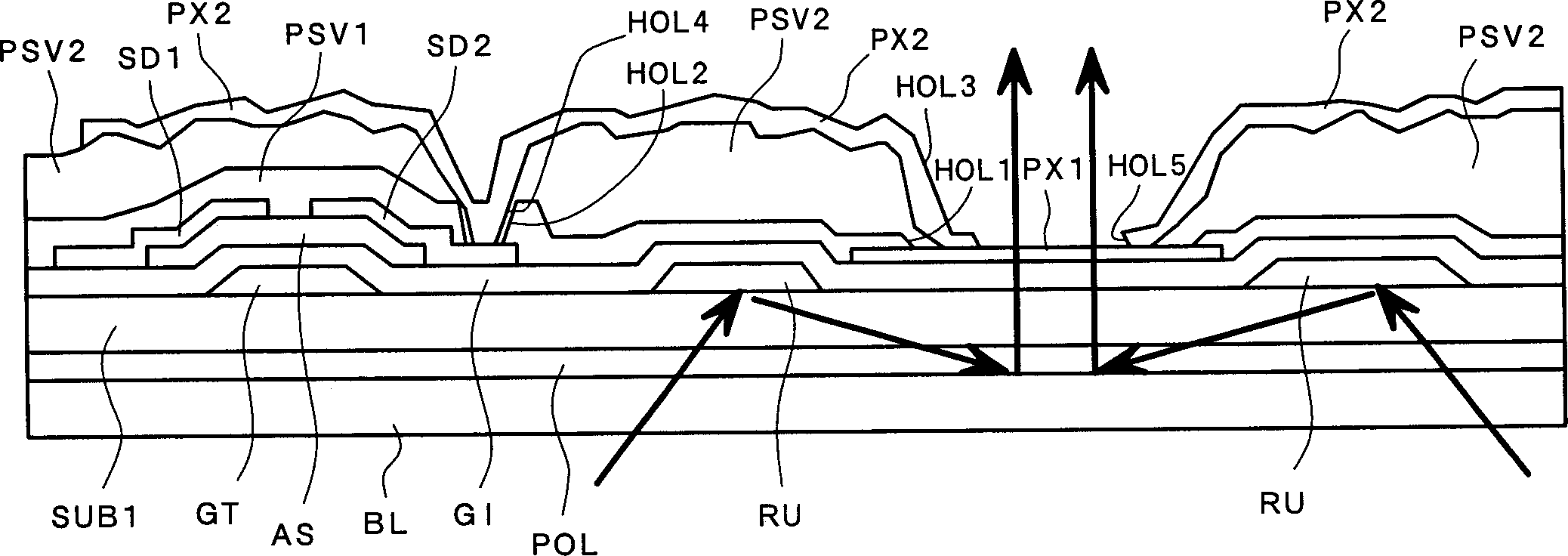

[0034] figure 2 It is a plan view of a pixel structure of a liquid crystal display device according to an embodiment of the present invention. also, figure 1 shows along the figure 2 Pixel cross-sectional view of midline I-I; image 3 shows along the figure 2 Pixel cross-sectional view of midline III-III.

[0035] figure 2 shows a plan view of a single pixel among the pixels arranged in a matrix, and the other pixels located around or above and below the pixel are similar in structure to the pixel shown.

[0036] exist figure 2 In this method, gate signal lines GL are first arranged on the surface of a transparent substrate SUB1 so that these lines extend along the "x" direction in the figure and are parallel to each other in the "y" direction.

[0037] As will be explained later, a region surrounded by these gate signal lines and drain signal lines extending along the “y” direction in the figure and parallel to each other in the “x” direction is defined as a pixel...

Embodiment 2

[0070] Figure 4 is a plan view of a pixel structure of a liquid crystal display device according to another embodiment of the present invention, corresponding to figure 2 . also, Figure 5 for along Figure 4 The midline V-V looks at the cross-sectional view of the pixel, while Figure 6 for along Figure 4 Cross-sectional view of midline VI-VI.

[0071] and figure 2 The difference in the structure shown in is that the light reuse film RU is integrated with the light reuse film RU in the adjacent pixel area along the x direction in the figure (ie along the extension direction of the gate signal line GL).

[0072] More specifically, the light reuse film RU extends to the bottom portion of the drain signal line DL.

[0073] As mentioned above, the drain signal line DL is made of the same material as the drain SD1 and source SD2 of the thin-film transistor TFT, and they are all made of continuously pressed or "multi-layered" high-melting-point metals (Mo, Ti, Ta, Cr) a...

Embodiment 3

[0083] Figure 7 It is a plan view of a pixel structure of a liquid crystal display device according to yet another embodiment of the present invention, corresponding to Figure 5 . in addition, Figure 8 for along Figure 7 Cross-sectional view of midline VIII-VIII.

[0084] Figure 7 The embodiment shown in the structure of embodiment 2 has been further improved. The main difference from Embodiment 2 is that the light reuse film RU is physically divided into fragments, and these fragments form many mutually separated light reuse films RU1 on the same layer (the upper surface of the electrically insulating film GI).

[0085]The reason for adopting such a split structure of the light reuse film RU is as follows: When one drain signal line DL is electrically short-circuited with the light reuse film RU below it for some reason, The capacitive coupling between the RU and the pixel electrode PX causes a potential change or deviation on the pixel electrode PX, and an operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com