Low-temp nuclear reactor with dead fuel for nuclear power station

A nuclear reactor and spent fuel technology, applied in the direction of reactor fuel materials, nuclear power generation, reduction of greenhouse gases, etc., can solve the problems of economy and safety that are not widely accepted, and achieve increased backup reactivity, reduced investment and operating costs, The effect of improving the utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

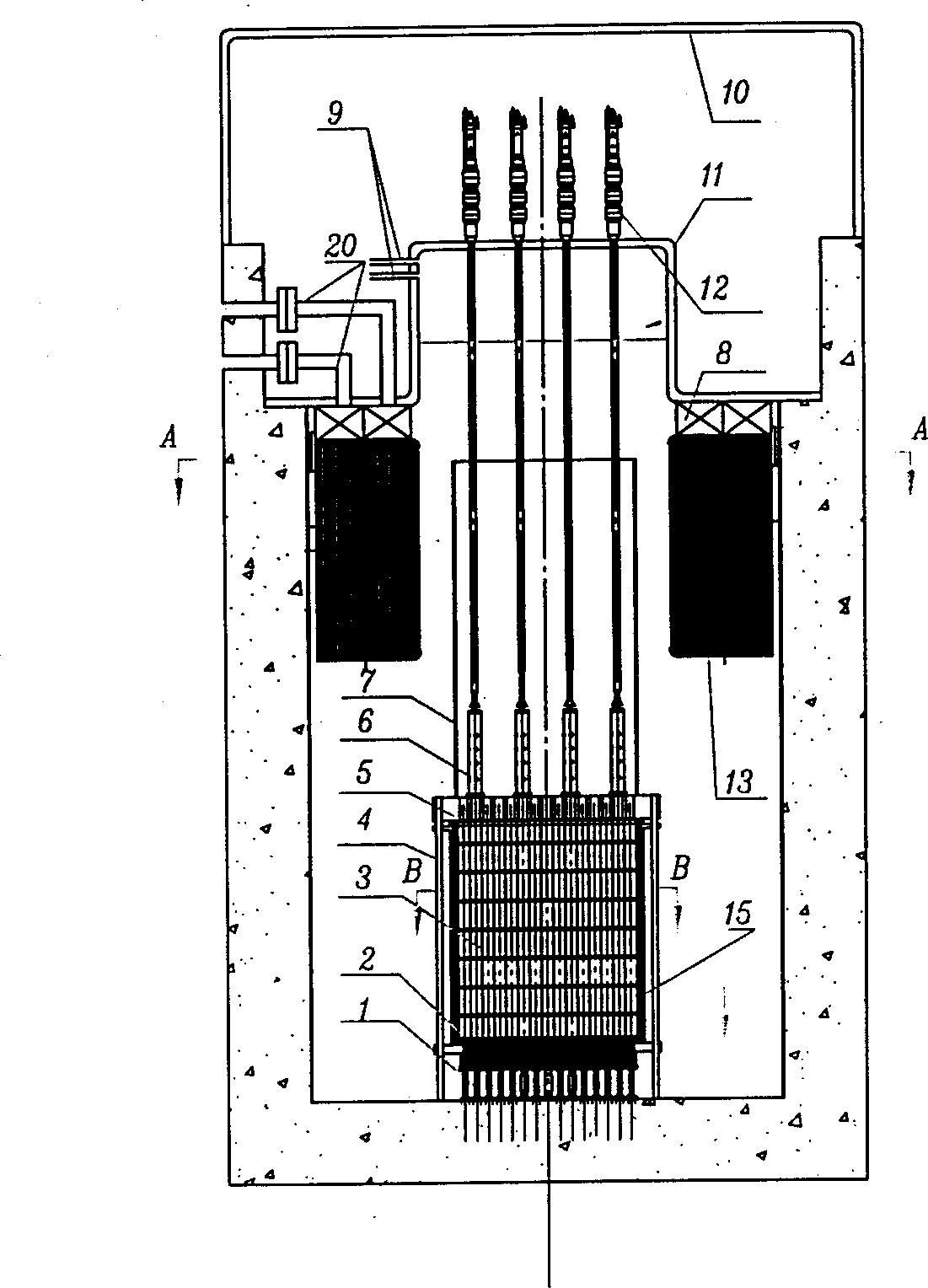

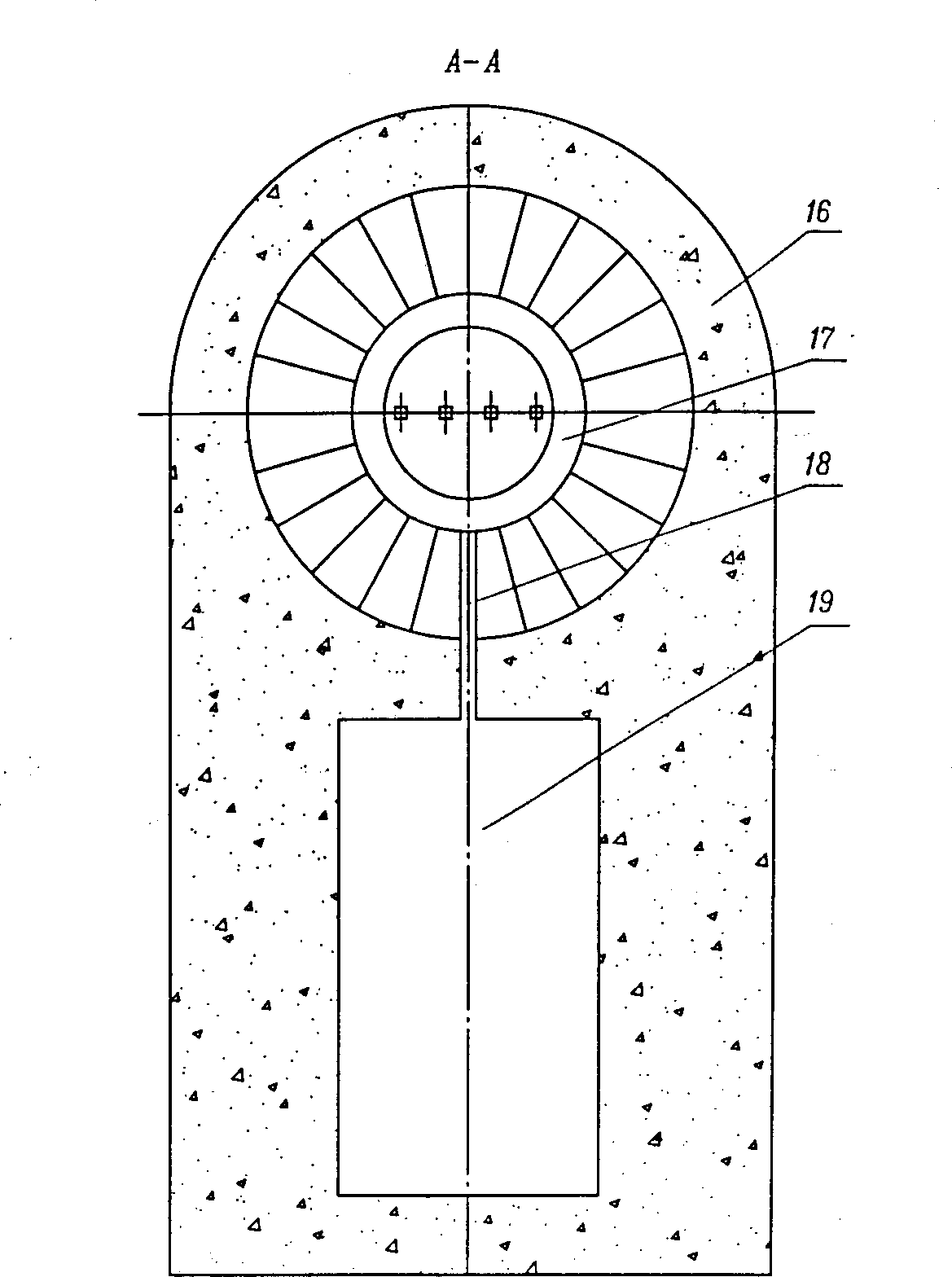

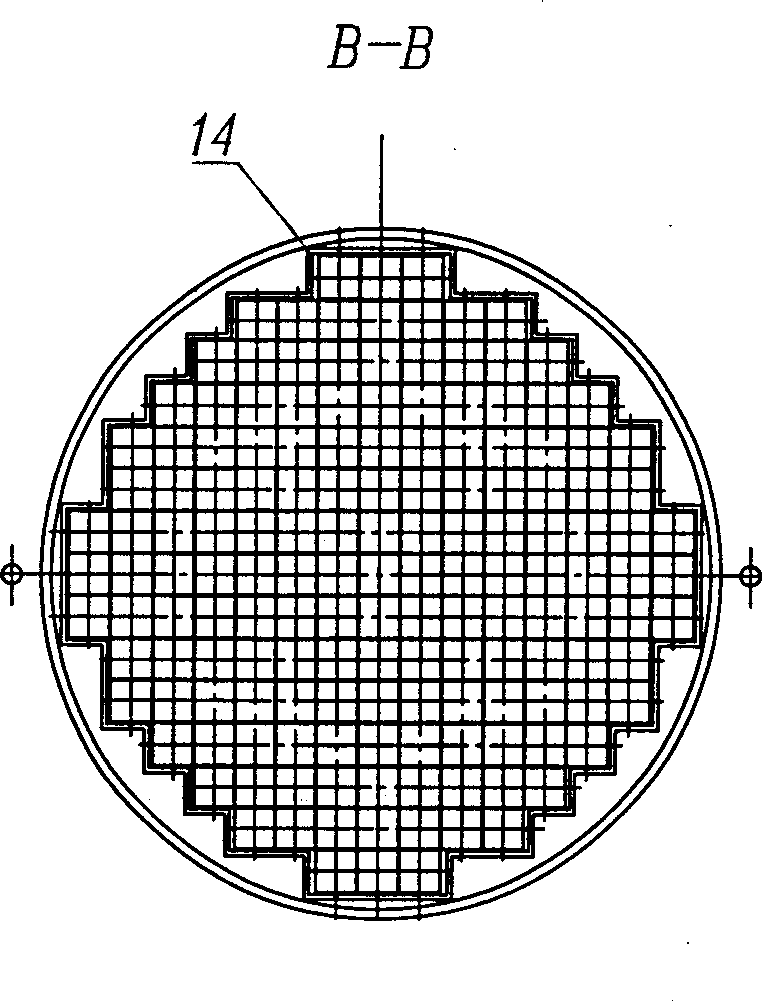

[0023] The present invention takes a heat supply pile with a thermal power of 200 megawatts as an example, and its structure is as follows: figure 1 , figure 2 , image 3 shown. A core pool 17 and a spent fuel storage pool 19 surrounded by a concrete biological shielding layer 16, the diameter of the core pool 17 is 7 meters, the water depth is 14 meters, and the thickness of the shielding layer is 1.5 meters; the width × length of the spent fuel storage pool 19 is About 5 meters x 9 meters, the water depth is 13 meters. A water channel 18 is provided on the side of the stack pool 17 to communicate with the spent fuel storage pool 19, and the spent fuel storage pool 19 can place spent fuel transport containers and spent fuel assembly storage racks. The concrete biological shielding layer 16 and the shielding layer of the spent fuel storage pool 19 are covered with stainless steel to ensure that the water pool 17 is watertight. The core of the reactor is composed of a lowe...

Embodiment 2

[0025] The difference from embodiment 1 is that the fuel assembly of the reactor core is unirradiated "fresh" fuel assembly as the reactor fuel, and one or two gas sealing shields are used on the upper part of the water pool. Since the upper part of the core water pool adopts double sealing and shielding, the first sealing and shielding can ensure that when the fuel element is damaged, the radioactive material is contained in the sealing and shielding. If it is charged with a certain pressure of gas, the subcooling degree of the coolant can also be improved so that the depth of the pool can be less than 15 meters. Therefore, this reactor has the main characteristics of both pool and shell reactors, and its water supply temperature is high while avoiding the release of radioactive gases to the environment. This makes the reactor a safe reactor type with "no radioactive environmental consequences". The seawater desalination plant is built along the coast, and the pool should no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com