Screen printing equipment and method

A technology of screen printing and cover plate, applied in screen printing, screen printing machine, printing and other directions, can solve problems such as hardening printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

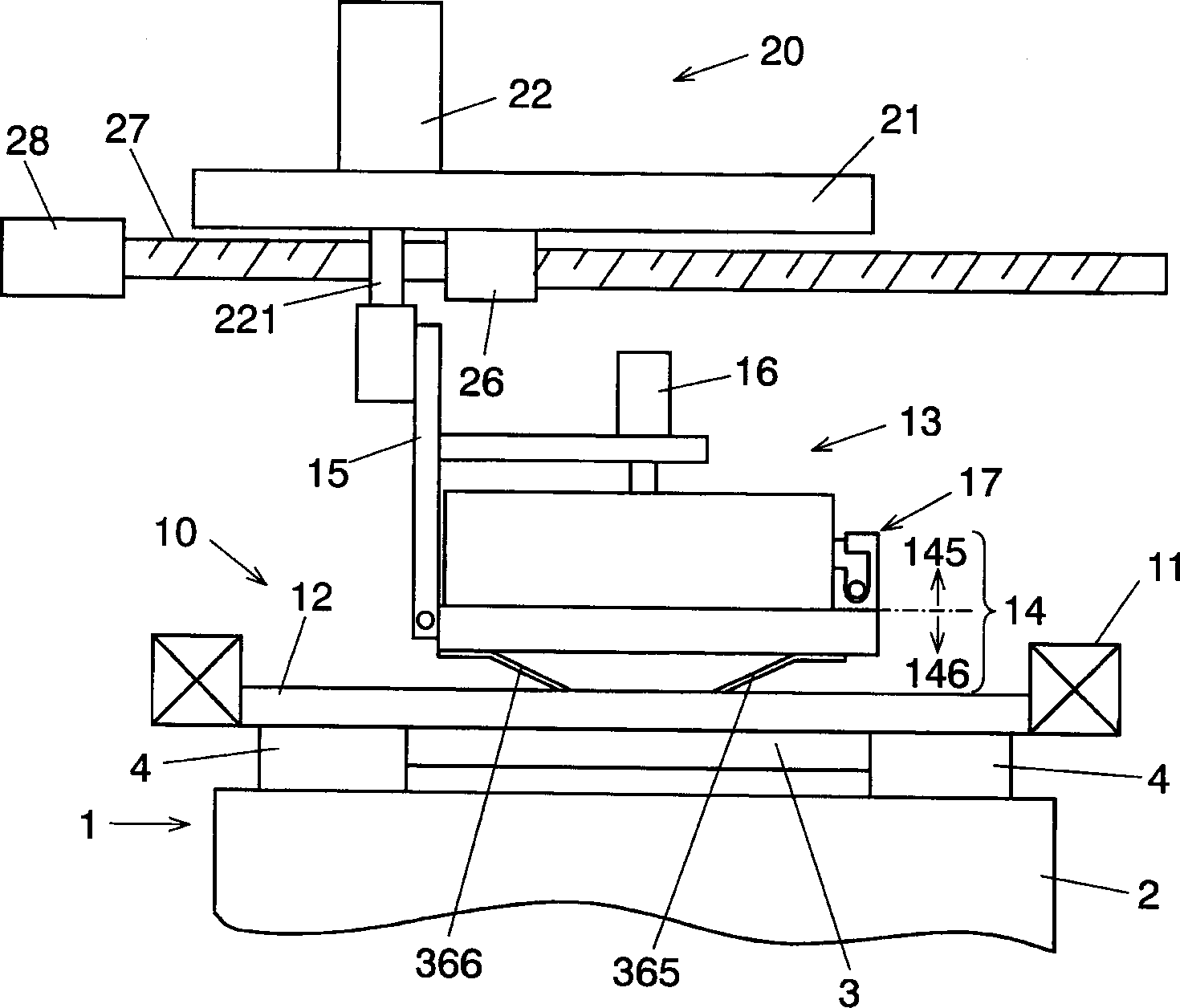

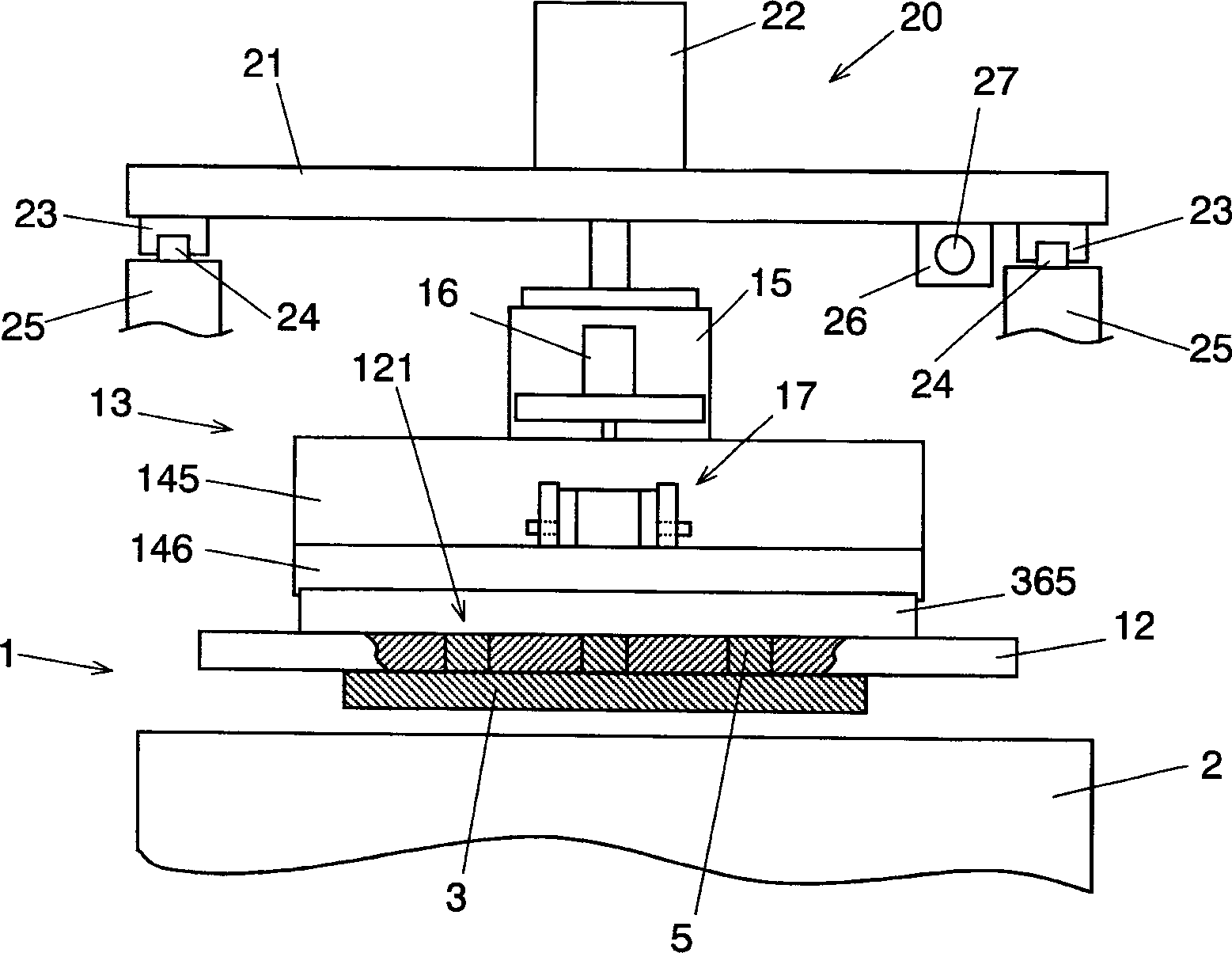

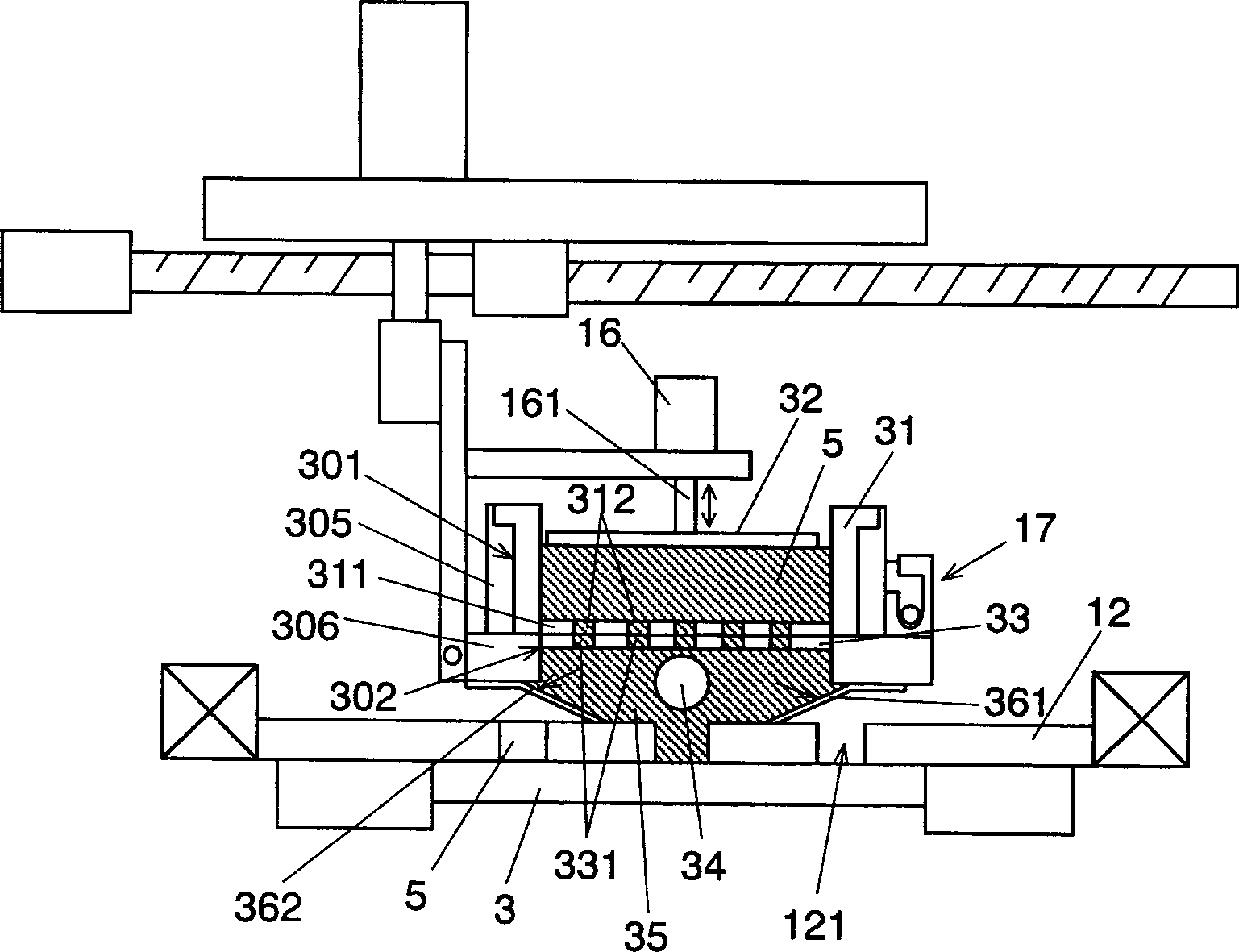

[0028] figure 1 is a front view of the screen printing device in Embodiment 1 of the present invention, figure 2 is a side view of the device, image 3 is a partial cross-sectional view of the device, Figure 4 , Figure 5A and Figure 5B yes figure 1 Partial cutaway view of the squeegee head in the screen printing setup shown. in Figure 5A It is a figure which assumes that there is no rectification part for explanation. Figure 6A and Figure 6B It is a partial sectional view of another squeegee head.

[0029] First, refer to figure 1 , figure 2 and image 3 The configuration of the screen printing device will be described. exist figure 1 and figure 2 Among them, the substrate positioning unit 1 is provided with a substrate support unit 2 on a moving table (not shown). The substrate 3 to be printed is held by the clamper 4 of the support part 2, and the position of the substrate 3 in the horizontal and vertical directions is determined by driving the moving...

Embodiment 2

[0054] Figure 7A It is a partial sectional view of the squeegee head of the screen printing device in Embodiment 2 of the present invention. Figure 7B is a partial perspective view of the squeegee head. This second embodiment is a screen printing apparatus in which the squeegee head 13 having the same structure as that shown in the above-mentioned embodiment 1 is provided with components different from those of the first embodiment in the flux storage portion 35 .

[0055] exist Figure 7A In the accommodating part 35, the spacer member 44 is arranged. Figure 7B The spacer member 44 shown in is a member that combines a plurality of partition plates 441 in the vertical direction into a lattice shape viewed from a plan view. When the solder paste 5 moves downward in the housing portion 35 , the solder paste 5 moves in the space between the partitions 441 . At this time, a considerable amount of solder in all solder paste volumes moves downward along the vicinity of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com