Fast repair technique and apparatus for damaged composite material in aircraft structure

A technology of structural damage and composite materials, which is applied in the fields of microwave rapid repair of aircraft structural damage composite materials, aircraft structural damage repair and war damage repair, which can solve the problem of increased peripheral equipment, increased investment, and inability to adapt to online products and metal structures. Repair needs and other issues, to achieve the effect of strong penetrating power, small thermal inertia, and excellent repair quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

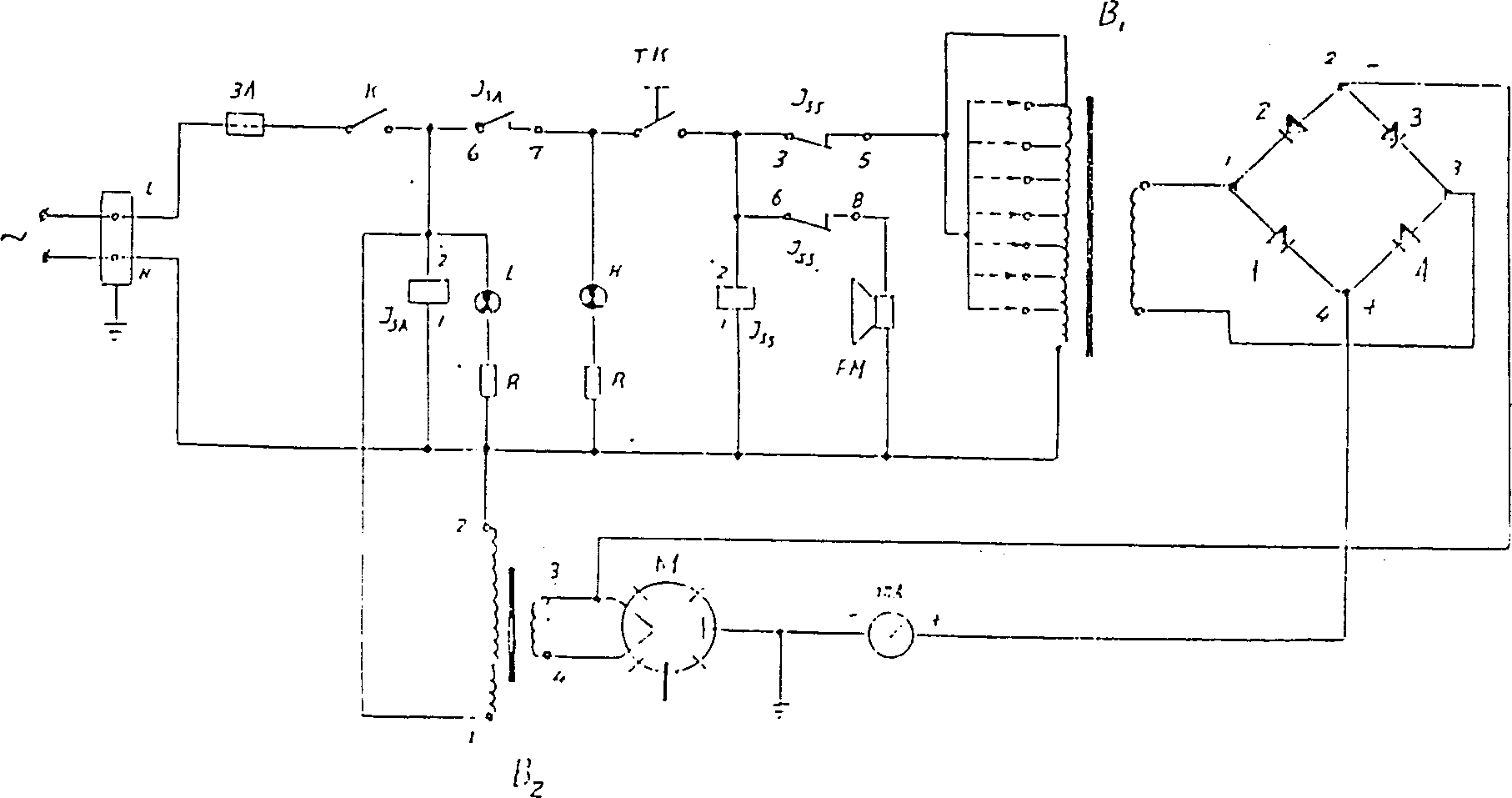

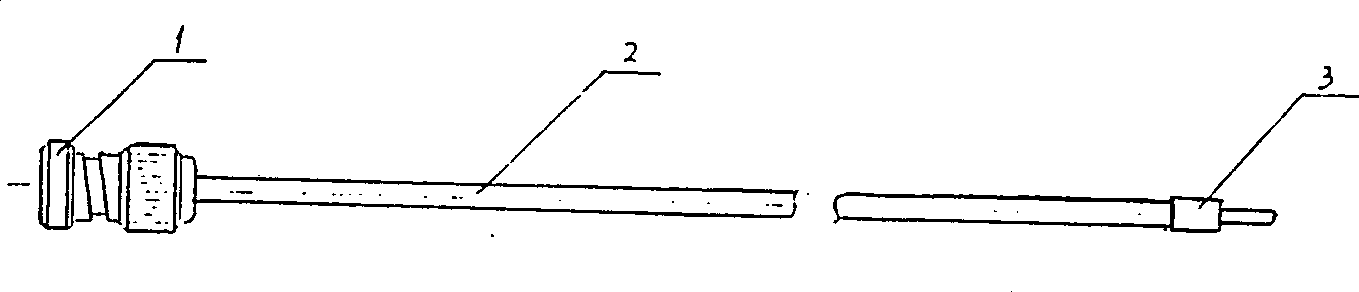

[0019] figure 1 It is a dedicated microwave power source of the present invention. The controllable autotransformer B1 provides the anode voltage of the magnetron M after bridge rectification, and the transformer B2 provides the filament voltage of the magnetron M. The control circuit consists of a time relay J SA 、J SS , composed of button switch K and foot switch TK. It has an automatic protection function: that is, J SA Provide magnetron M high-voltage time-delay protection; and J SS Provide magnetron M adjustable time-delay circuit breaker protection, which controls the working time of magnetron M, and is prompted by buzzer FM with sound signal. The magnetron M is the core component, and the frequency of microwave radiation is determined by it. In order to facilitate field repair, a continuous microwave oscillator with a transmission power of 200W and an operating frequency of 2450MHZ is used. Or 915MHZ, when it is less than 200W, the coaxial cable output is used, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com