Laminated product with surface protective layer

A technology for laminates and protective layers, applied in the field of laminated floor tiles or laminates, can solve the problems of difficult to manufacture highly designable color laminates, difficult to print patterns, etc., to achieve excellent wear resistance and The effect of chemical resistance, resistance to stains, and shortened construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

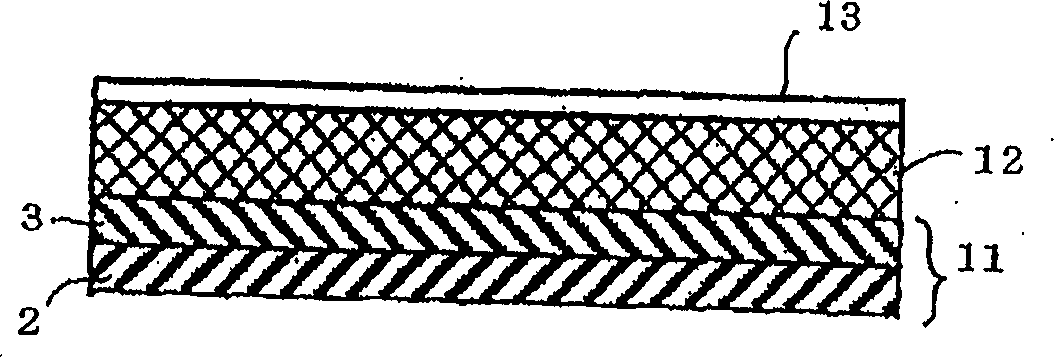

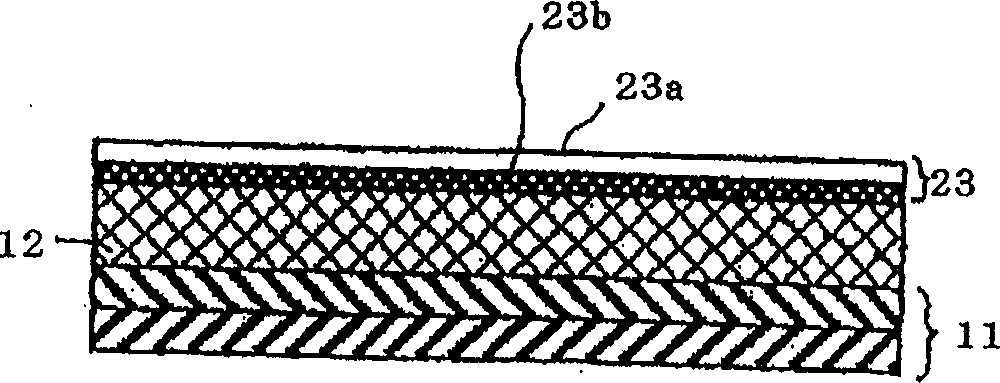

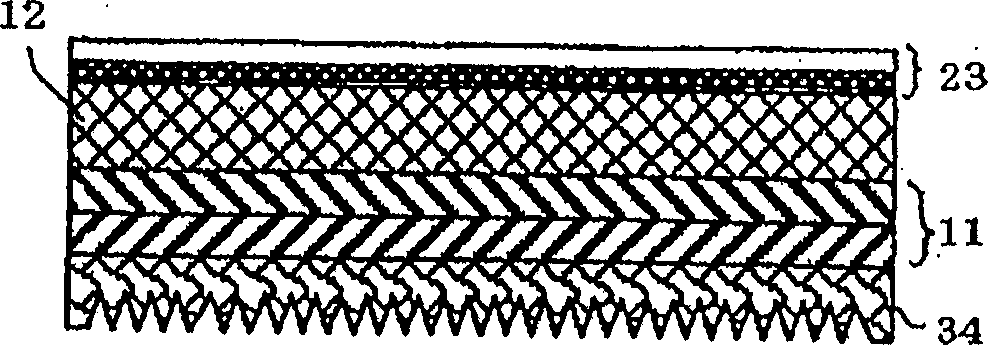

[0074] image 3 is a cross-sectional view of a laminate drawn according to a third embodiment of the present invention. image 3 in, with figure 1 or 2 corresponding parts are marked with the same number.

[0075] The laminated product of the third embodiment is composed of a fiber-reinforced resin layer 11, an elastic layer 12 (laminated on one side of the fiber-reinforced resin), a surface protection layer 23 (laminated on the elastic layer), and a support layer 34 (laminated on the on the other side of the fiber-reinforced resin layer).

[0076] Since the fiber-reinforced resin layer 11 and the elastic layer 12 are similar to those described in the first embodiment, and the surface protection layer 23 is similar to that described in the second embodiment, their descriptions will be omitted below, and the supporting layer 34 will be described in detail.

[0077] The support layer 34 serves to improve the adhesion of the laminate to the substrate. There are several exampl...

no. 4 example

[0079] Figure 4 is a schematic cross-sectional structure diagram of a laminated product according to a fourth embodiment of the present invention. Figure 4 in, with figure 1 or 2 corresponding parts are marked with the same number.

[0080] The laminated product described in the fourth embodiment of the present invention consists of a fiber-reinforced resin layer 11, an elastic layer 12 (laminated on one side of the fiber-reinforced resin layer 11), a surface cover layer 23 (laminated on the elastic layer 12 ) and a second elastic layer 45 (of the same or different type as the elastic layer 12, laminated on the other side of the fiber-reinforced resin layer).

[0081] Since the fiber-reinforced resin layer 11, the elastic layer 12, and the surface protective layer 23 are similar to those described in the third embodiment, these compounds will be omitted in the following description.

[0082] Even without the second elastic layer 45, the required dimensional stability of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coefficient of linear expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com