Method for paying-off by utilizing overhead line and equipment for implementing said method

An overhead line and traction device technology, which is applied in the directions of overhead line/cable equipment, cable installation, cable installation device, etc., can solve the problems of difficult construction, difficult to control, and difficult to meet the needs of overhead line payout construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

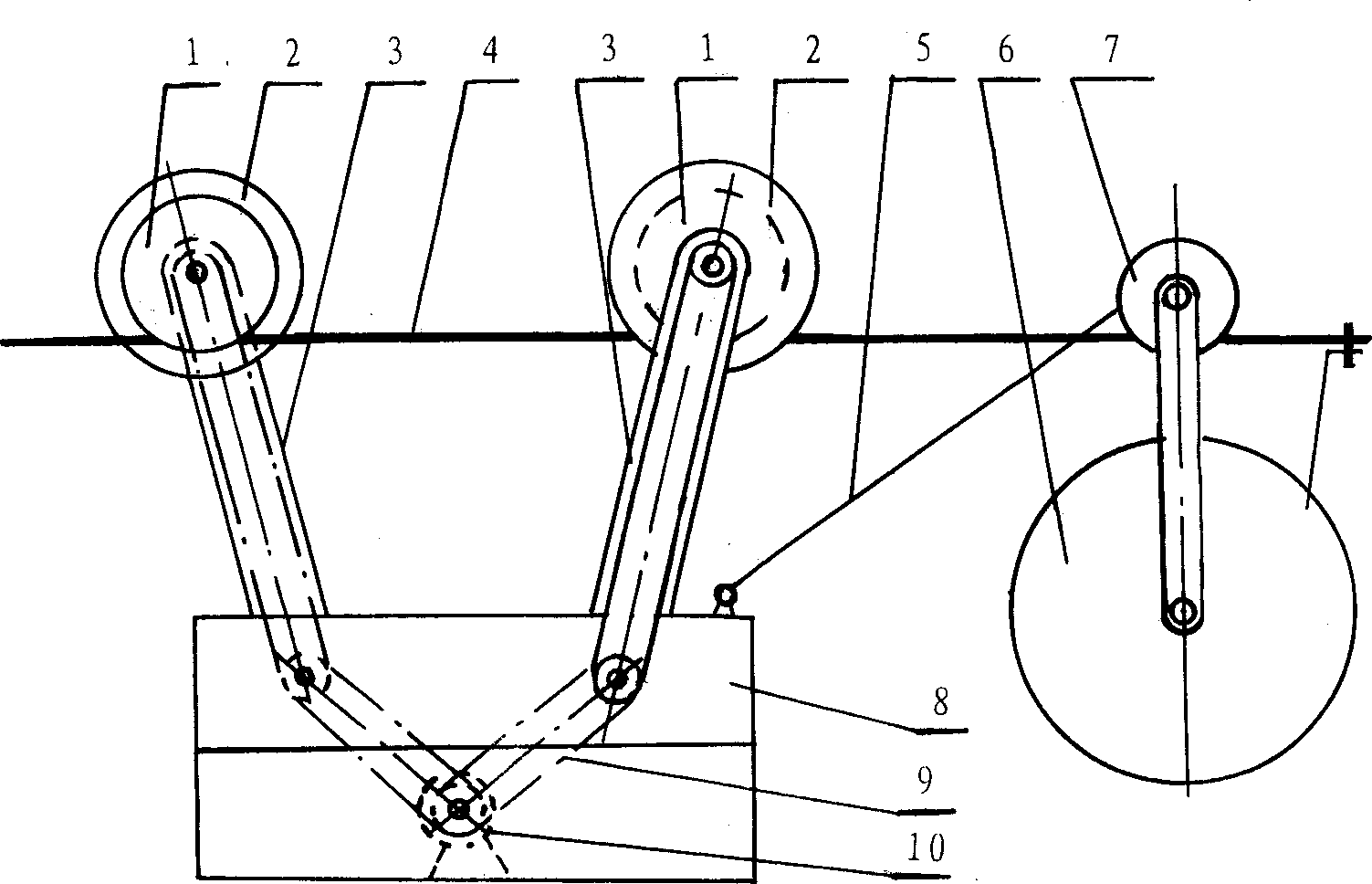

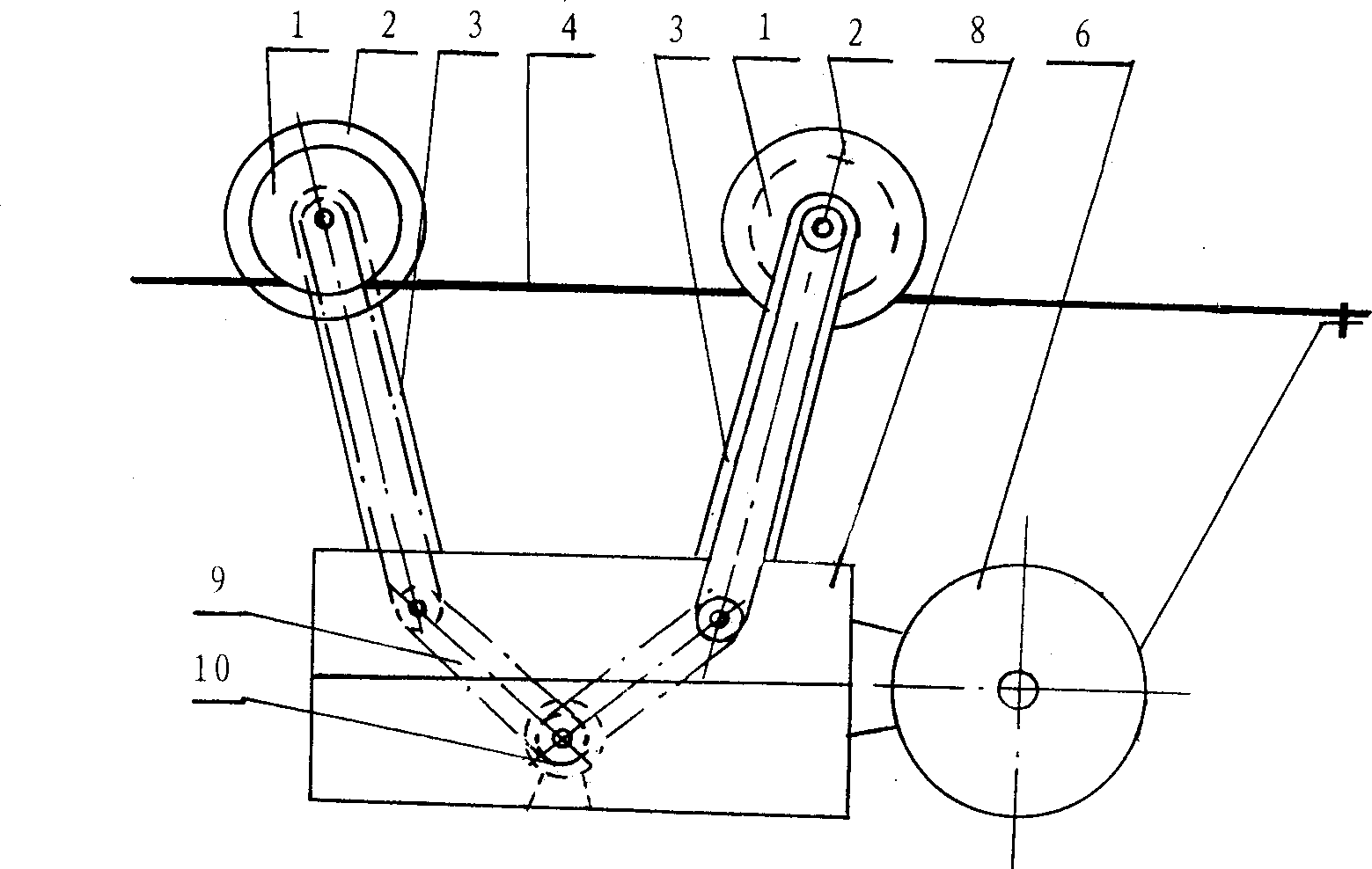

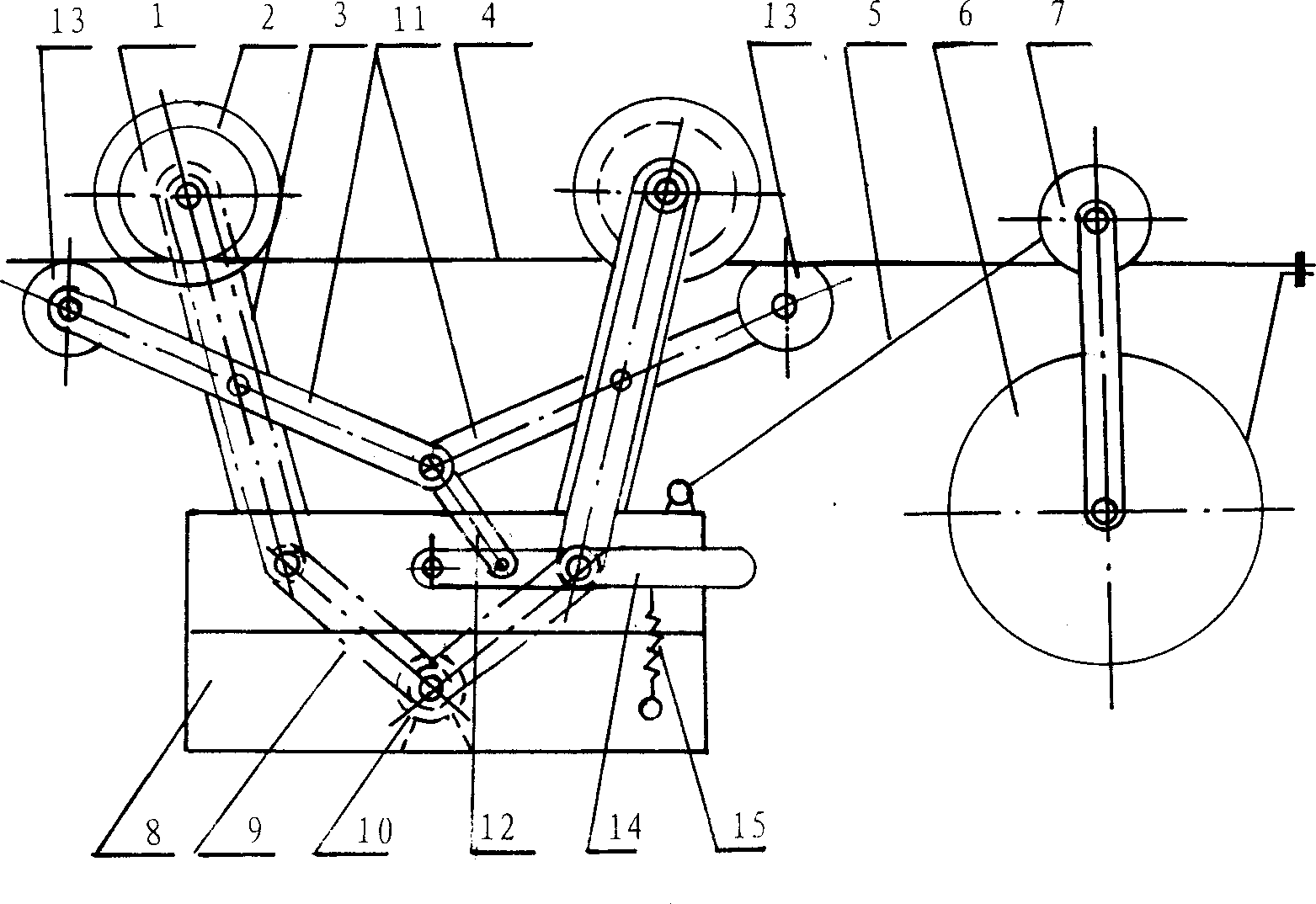

[0019] The invention provides a method of using the wires on the existing overhead line, which is to hoist the traction device with power on the overhead line through tools, the traction device and the overhead wire 4 roll and rub against each other, and one end of the traction device is directly connected to the overhead line. Cable connection, by manipulating the wireless remote control, the traction device with the corresponding remote control actuator built in can roll along the overhead line with its own wire, cable or directly drag the wire and cable to complete the start-up required for the release of the wire. , Stop, forward, reverse, accelerate, decelerate and other required actions, arrive at the designated destination, and complete the laying-out construction operation. Such as figure 1 As shown, the traction device is used in conjunction with the wire reel 6, the wire reel 6 is suspended on the overhead wire 4 through a driven wheel 7, and the wire reel 6 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com