Automatic sampler and probe using same

An automatic sampling and probe technology, applied in the field of liquid chromatography analysis, can solve problems such as cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

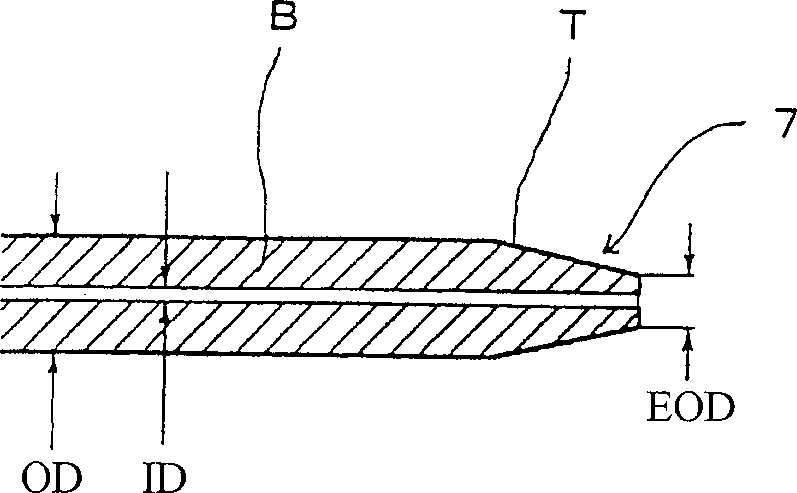

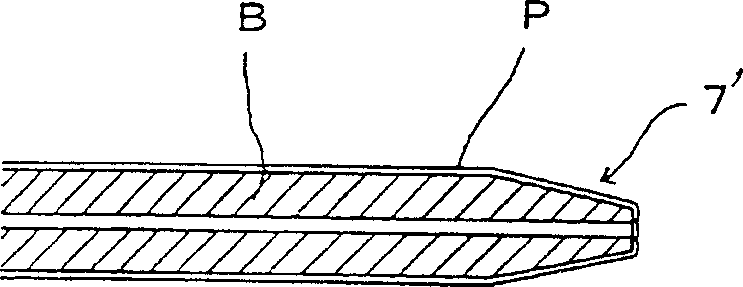

[0021] Figure 1A and 1B Probes according to the first and second embodiments of the present invention are shown, respectively.

[0022] Figure 1A The probe 7 shown is a blunt probe with an outer diameter OD of 1.2 mm and an inner diameter ID of 0.5 mm, the outer diameter EOD of the blunt end being 0.65 mm. The base metal B is stainless steel, and the surface of the base metal B is coated with a platinum plating layer T with a thickness of several micrometers (μm). The surface of the probe is covered with a platinum coating T whose adsorption activity is much lower than that of stainless steel. Therefore, when probe 7 is used for Figure 4 With the autosampler shown, chemisorption on the probe 7 surface is constrained, which in turn reduces cross-contamination.

[0023] exist Figure 1B In the probe 7' shown, the base metal B is coated with a synthetic resin coating P (approximately 300 [mu]m thick) instead of metal plating as used in the first embodiment. The synthetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com