Double-frequency vertical-ring pulsed high-gradient magnetic dressing machine

A high gradient magnetic separator and double pulse technology, applied in the field of magnetic separators, can solve the problems of increased investment and operating costs, large metal losses, and difficulty in ensuring the quality of concentrates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

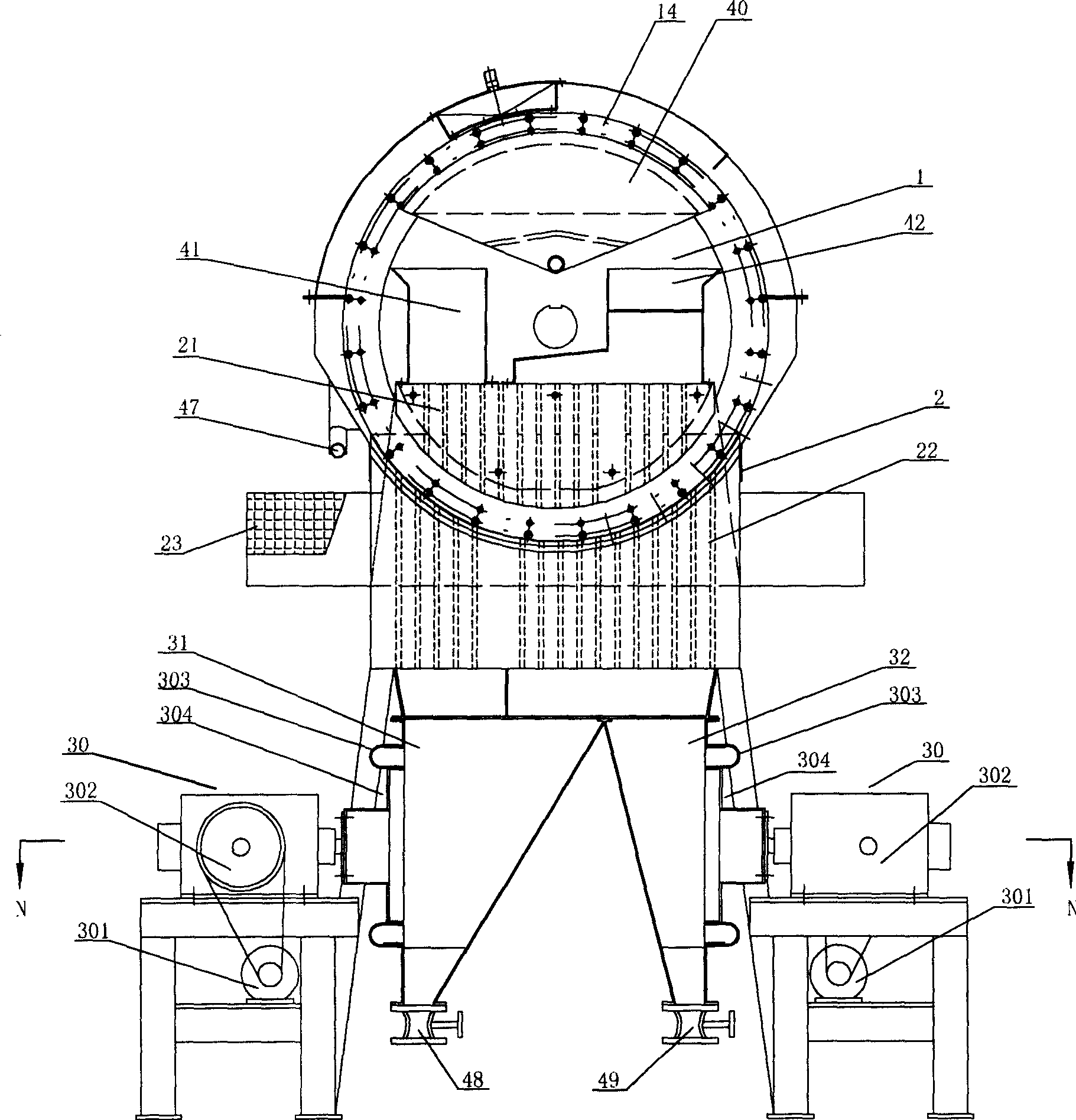

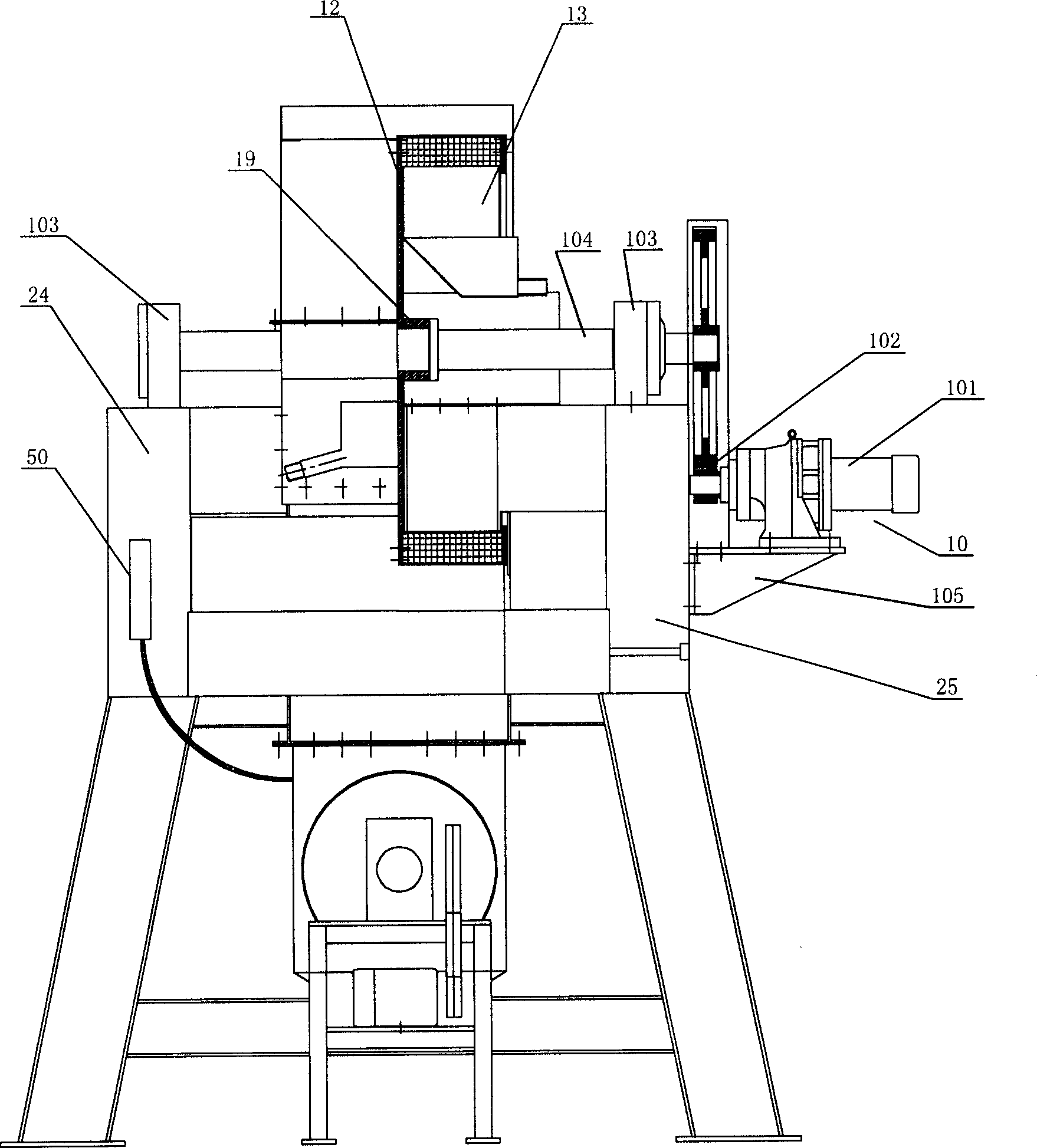

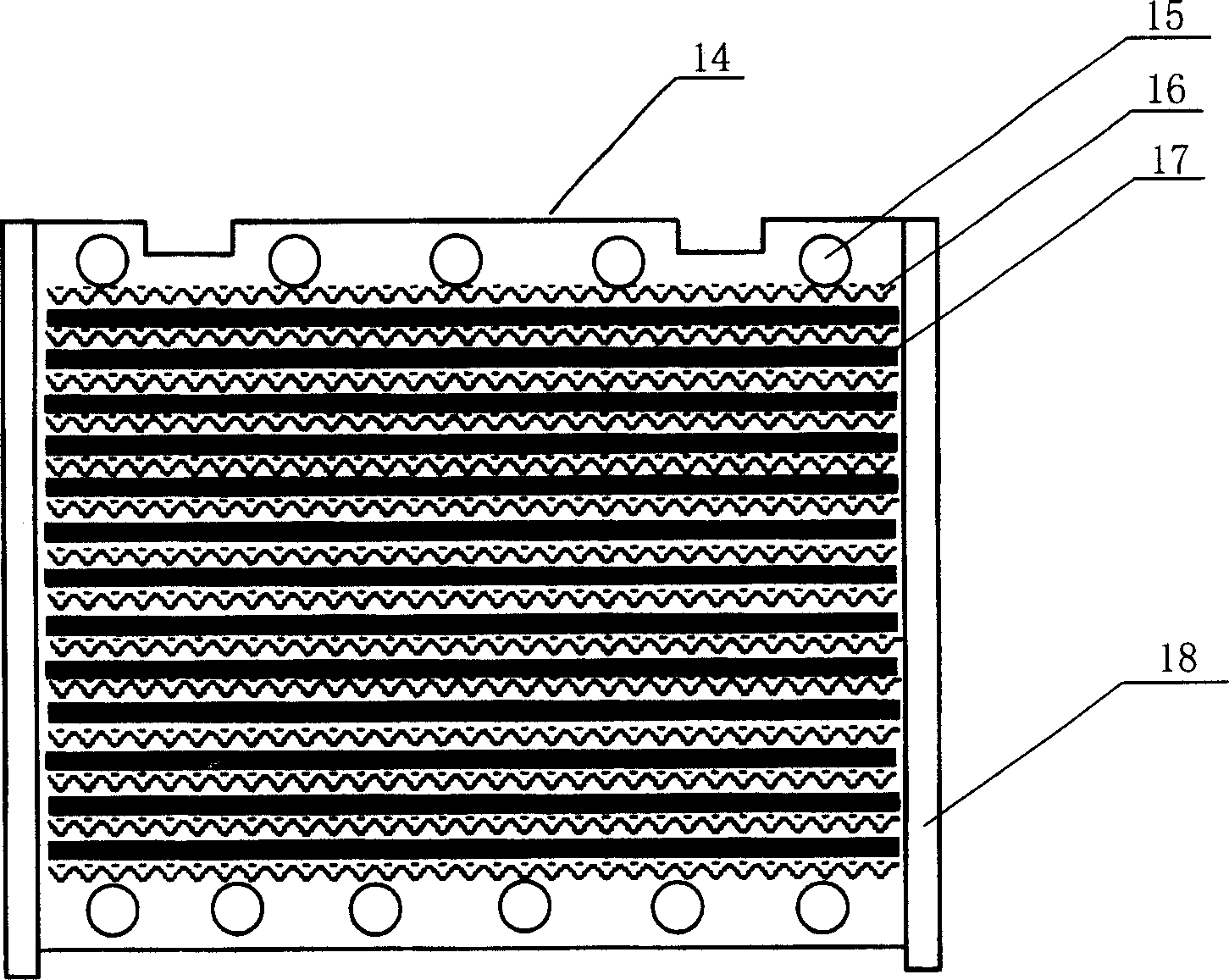

[0017] Such as figure 1 , figure 2 , Figure 4 As shown, the present invention includes a sorting ring 1, a magnetic pole 2, and a double-pulse device 3. The sorting ring 1 is composed of a thick-walled ring, a thin-walled ring, a magnetic medium, and bolts, wherein the ring body 13 is a vertical double-ring structure, and the ring body 13 is a vertical double-ring structure. There is a turntable 12 that connects the double rings as a whole, and a shaft sleeve 19 with a bearing is arranged in the turntable 12. Arc grooves are arranged around the ring body 13, and magnetic medium stacks 14 are respectively arranged in the arc grooves. The above magnetic medium stacks 14 are as follows: image 3 As shown, it includes a medium bead 15, a magnetic gathering medium 16, a medium spacer 17, and a medium box 18, wherein the magnetic gathering medium 16 and the medium spacer 17 are set as interlayers, and are fixed by the medium bead 15 and loaded with a matching medium box of 18. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com