Plant uproot device

A plant-integrated technology, applied in the fields of botanical equipment and methods, cutting tools, cutting equipment, etc., can solve the problems of increasing the diameter and wall thickness of the drive shaft, the drive shaft cannot achieve durability, and the complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

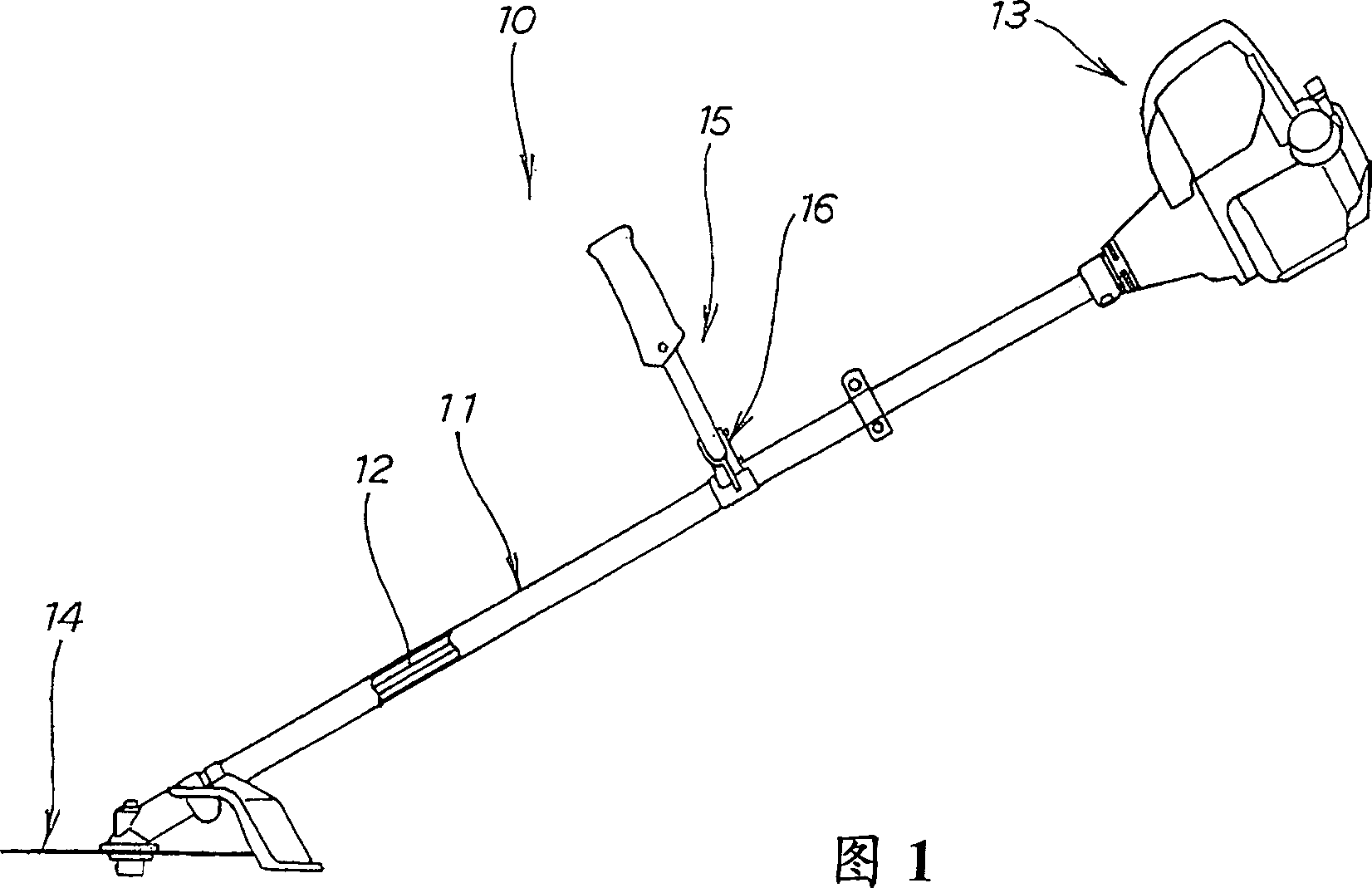

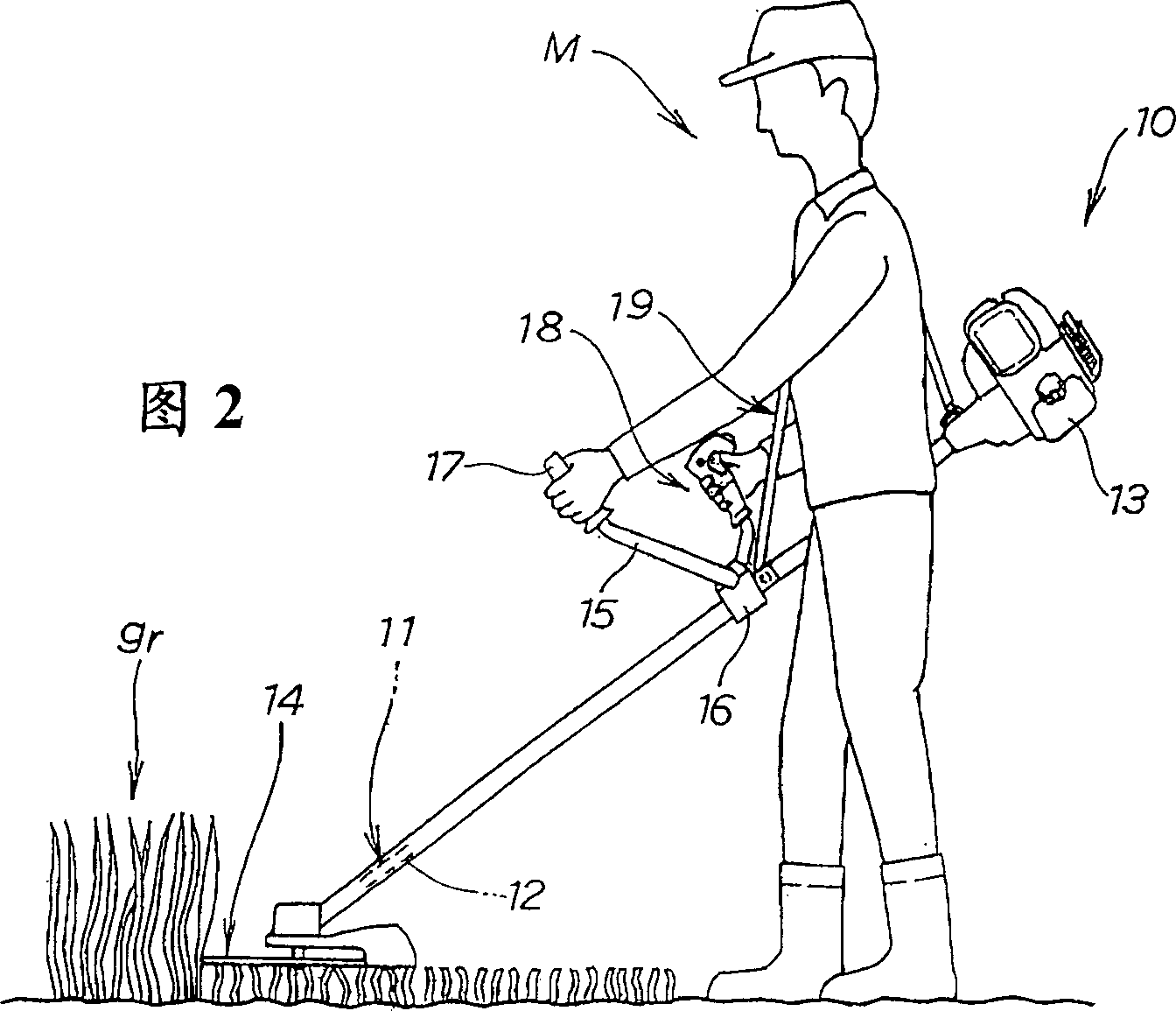

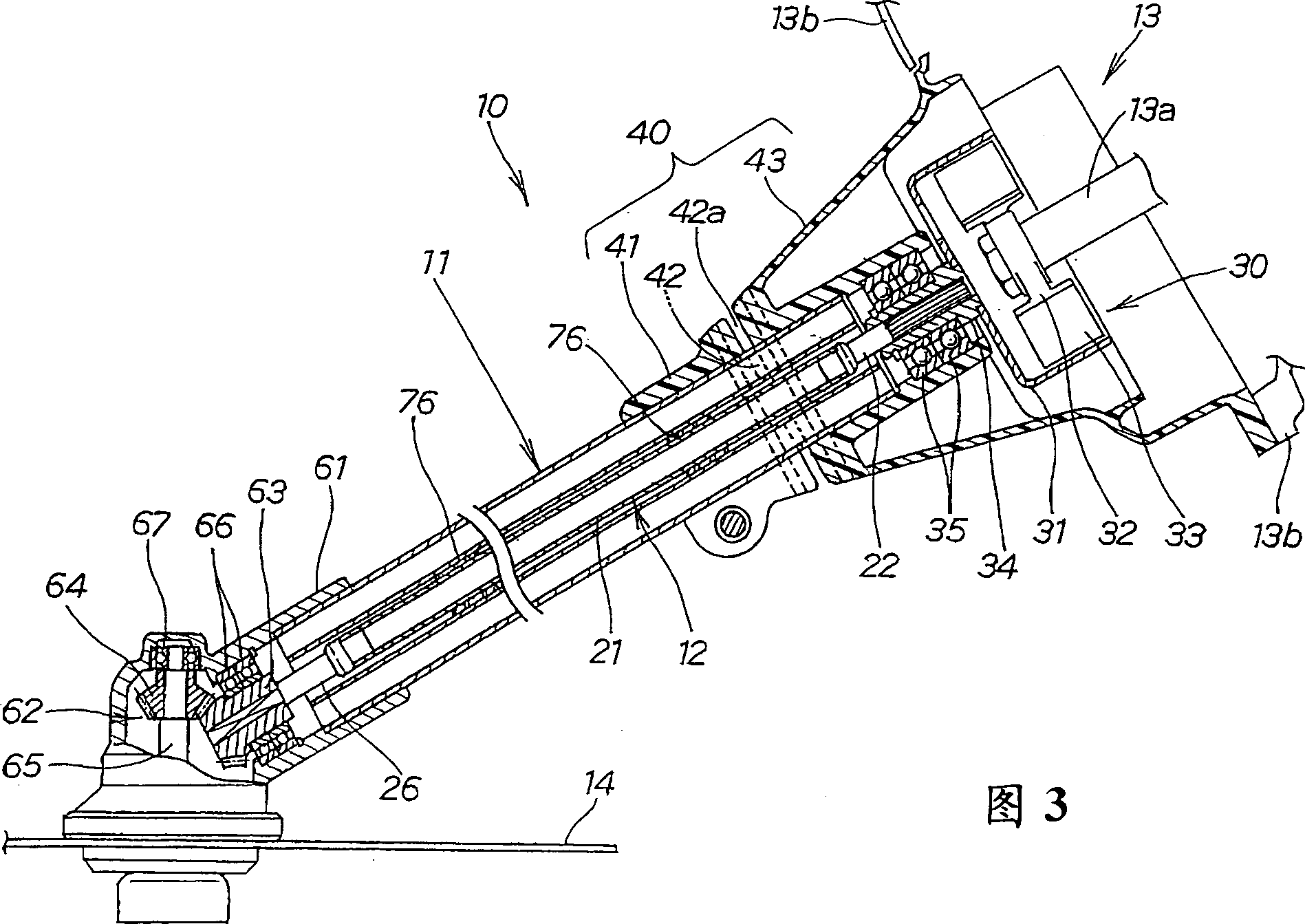

[0020] Figures 1 and 2 show a vegetation removal device 10 according to the invention which can be used to remove unwanted vegetation such as shrubs, weeds or grasses. The plant removal device 10 comprises: a tubular operating rod 11, a driving force transmission shaft or a drive shaft 12 passing through the operating rod 11, a prime mover or a driving source device 13 installed at one end of the operating rod 11, such as a motor or an electric motor, And the cutting blade 14 installed on the other end of the operating rod 11. The drive shaft 12 can be rotated by actuating the drive source device 13 , and therefore, the cutting blade 14 can be rotated by the drive source device 13 through the drive shaft 12 . The plant removal device 10 also includes a U-shaped handle 15 fixed at a substantially middle position in the longitudinal direction of the operating rod 11 . Specifically, the handle 15 is fixed to the operating rod 11 via a handle frame 16 and has left and right handl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com