Method for production of electric energy and MHD generator therefor

A technology of magnetohydrodynamics and generators, applied in the field of power engineering, can solve problems such as not meeting ecological safety requirements, complex stability, and low device efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

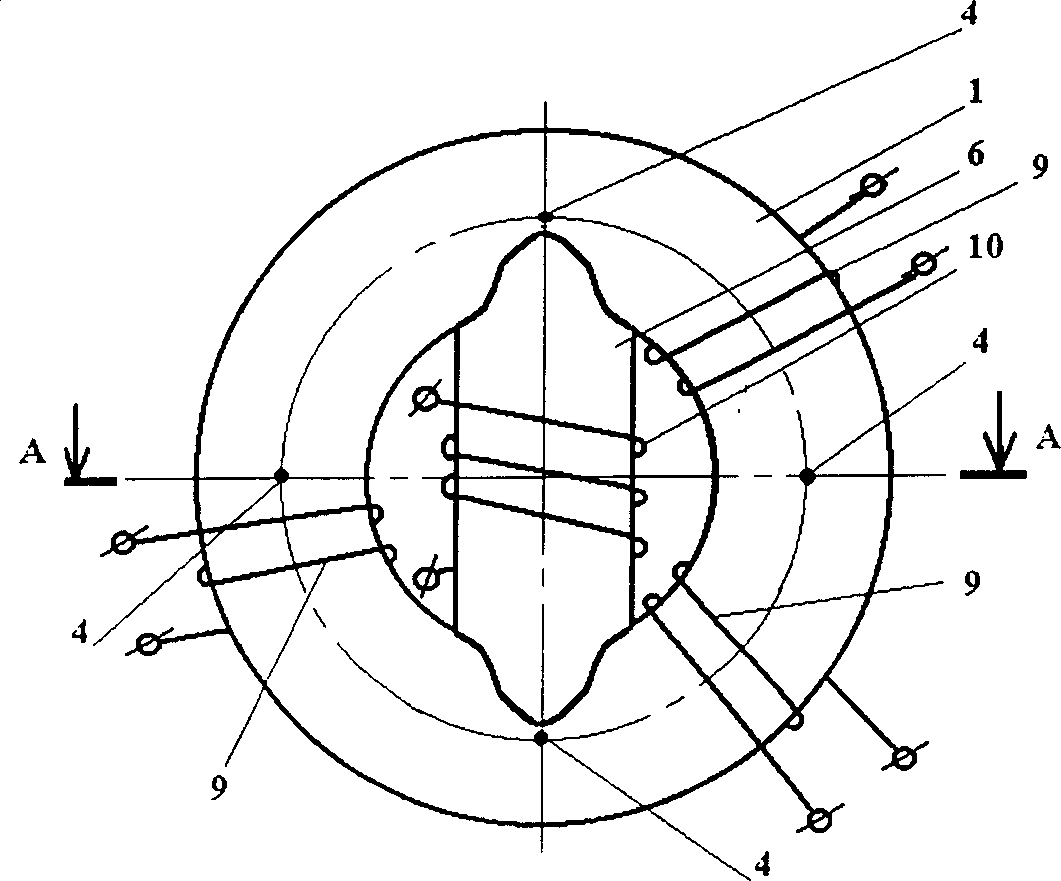

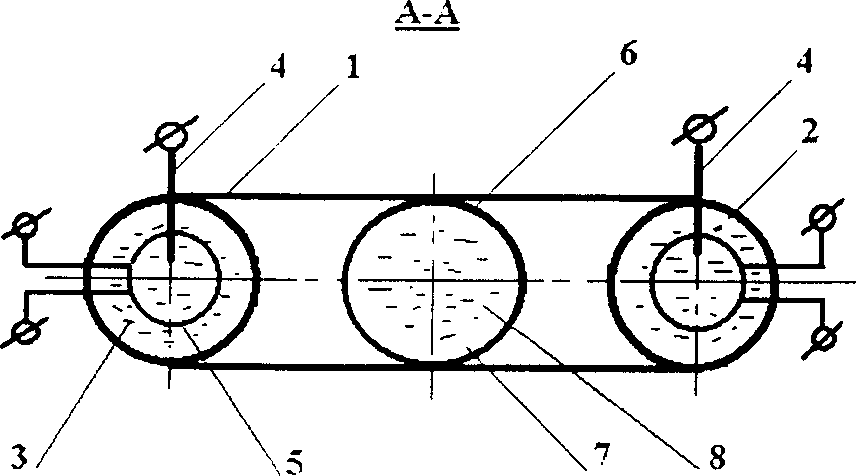

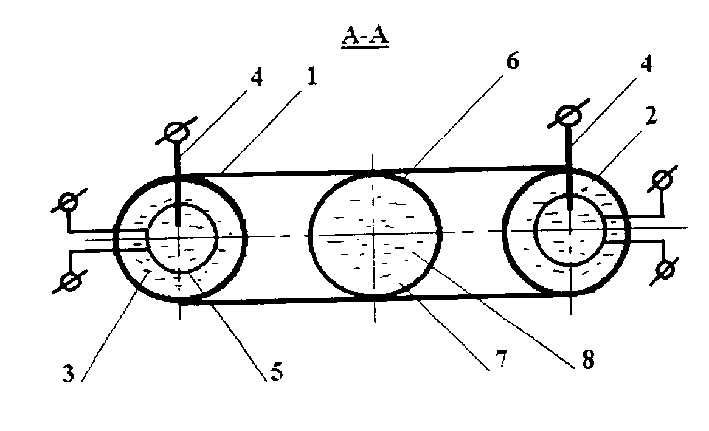

[0019] The invention is illustrated by the example of Gritskevich's generator.

[0020] The magnetohydrodynamic generator comprises a hollow, sealed annular cermet body 1 whose inner surface is covered with a coating 2 having a synergistic effect, and a cavity filled with distilled water 3 added with weighted water. In the channel of the main body 1, there are electrodes 4 made of hard alloy material connected to the capacitor bank, and field windings 5 connected to the power supply. Inside the ring of the main body 1, there is a composite cylindrical stabilization chamber 6 made of cermet, which communicates with the channel of the main body 1. The inner surface of the chamber 6 is also covered with a synergistic coating 7 and the cavity is filled with distilled water 8 added with heavy water. The main body 1 and the chamber 6 have power windings 9 and 10 on their exterior.

[0021] The magnetohydrodynamic generator operates in the following way: the water 3 which has bee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com