Power filling method and apparatus

A powder filling and powder technology, applied in the field of methods and devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

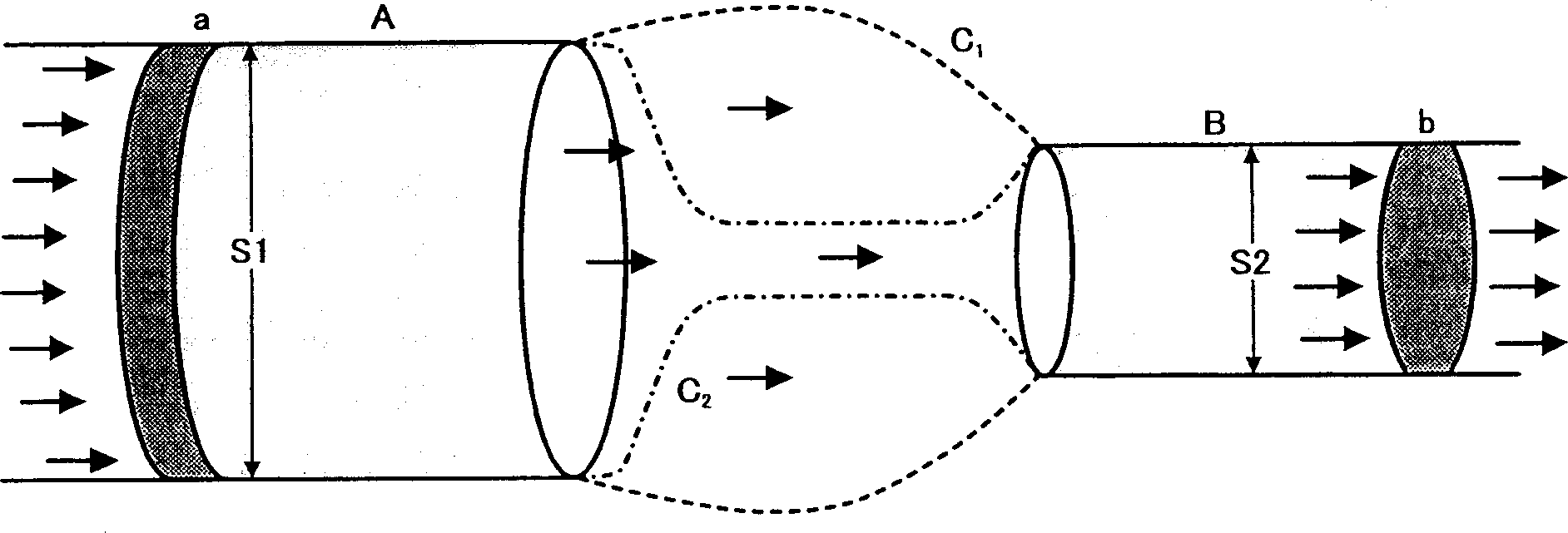

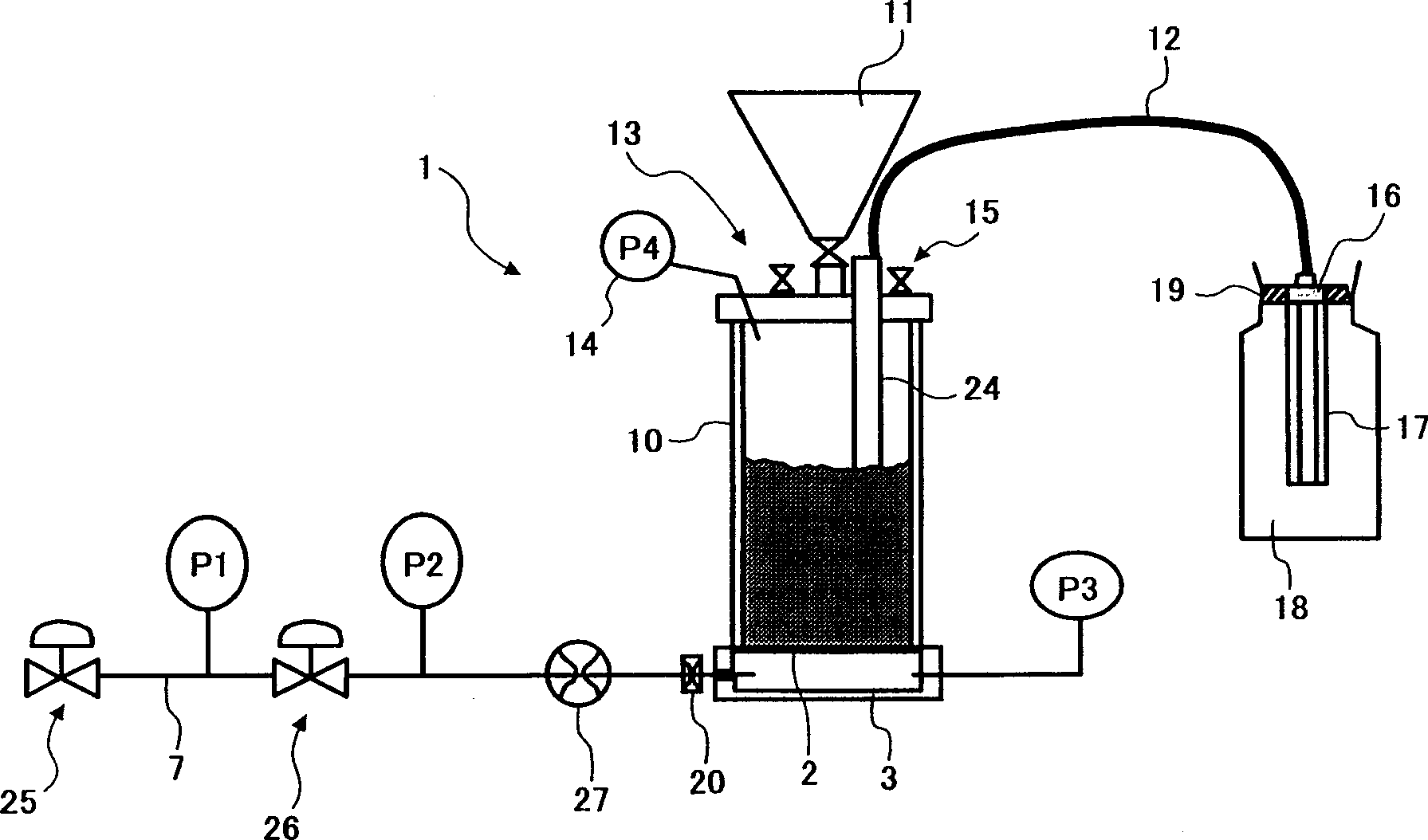

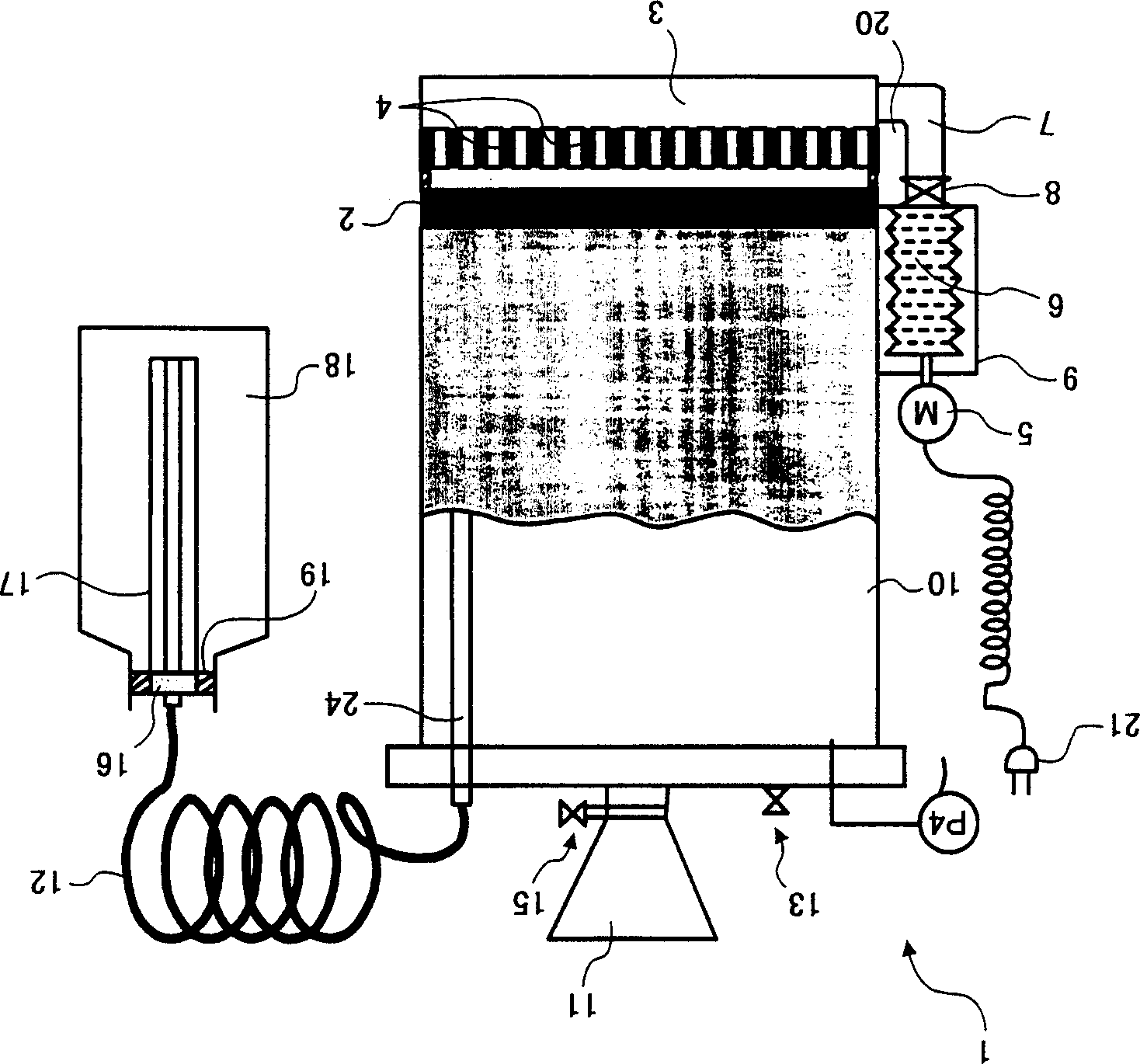

[0017] Systems that fluidize powder with gas and transport the powder pneumatically, for example through a tube, are available. However, this system has a problem when toner or the like with a particle size of 20 μm or less, especially 10 μm or less, is fluidized and filled in the toner container. In this case, the powder needs to be prevented from flying and the gas needs to be discharged from the container after filling. Although equipment that meets this requirement can be installed in a factory or similar large-scale facility, it is not suitable for ordinary offices.

[0018] Toner or similar fine powders have a very large surface area to volume ratio, and in many cases they adhere to each other, so they need to be loosened, for example, by a stirrer before use. The loose powder mainly reflects the surface condition of the block being ground to make the powder and has nothing to do with the specific gravity of the block, so Brownian motion continues. As is known from experienc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com