Method and apparatus for measuring light transmissivity

A technology of light transmittance and measuring equipment, applied in the direction of transmittance measurement, measuring device, testing optical performance, etc., can solve problems such as errors, adverse effects of measurement convenience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A method for measuring light transmittance and an apparatus for measuring light transmittance as embodiments of the present invention will be described below with reference to the accompanying drawings.

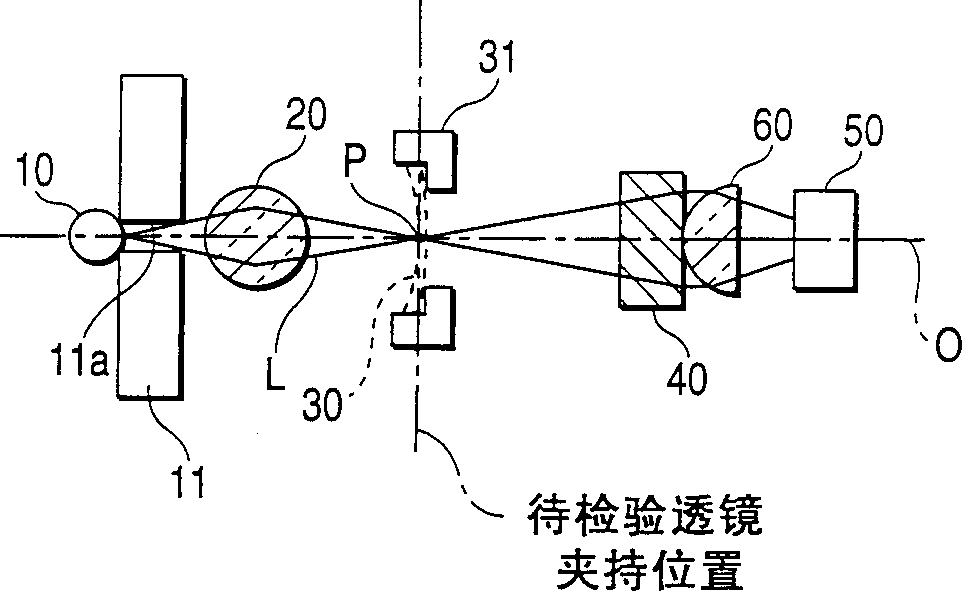

[0029] The apparatus for measuring light transmittance of the present invention includes two apparatuses for measuring light transmittance having the same optical system and different measurement wavelengths. figure 1 One of these two devices is drawn in and not the other.

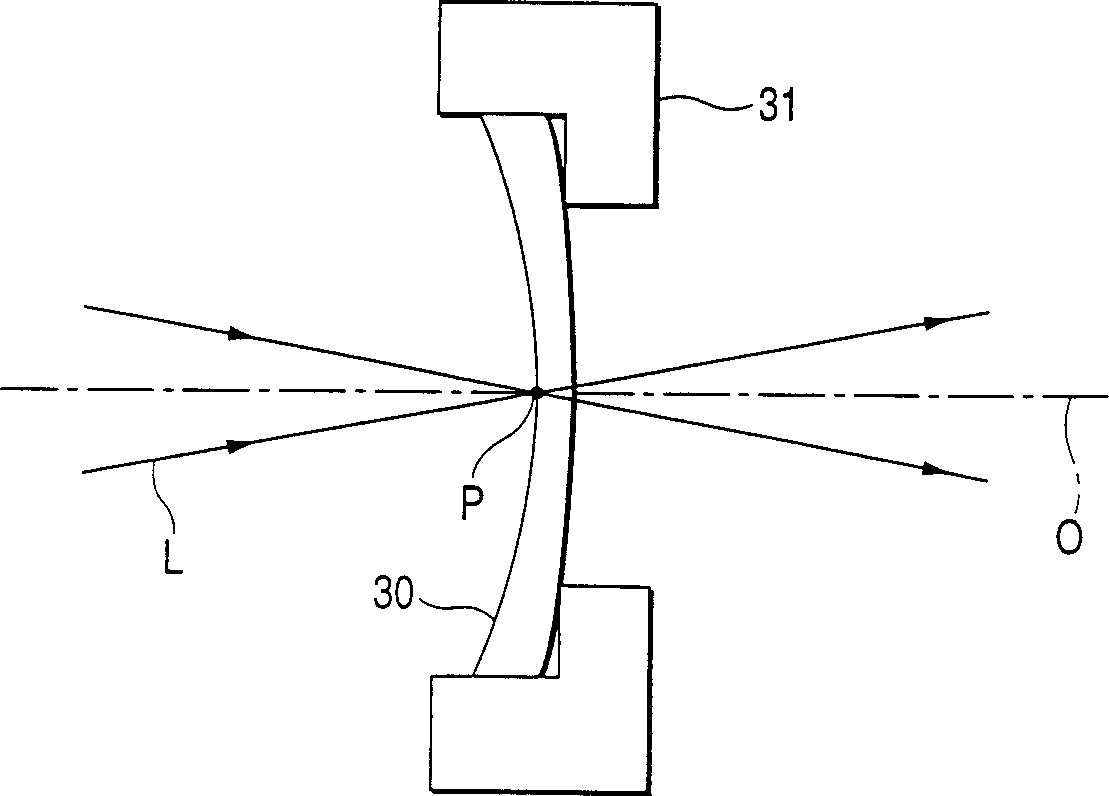

[0030] exist figure 1 Among them, the light source 10, the small hole plate 11, the ball lens 20, the lens holding device 31 to be inspected, the interference filter 40, the hemispherical lens 60 and the light receiving element 50 are arranged in such a way that the optical axes are on the same optical axis O figure 1 Set in sequence from left to right.

[0031] The light source 10 emits measurement light L. As shown in FIG. A light emitter that emits light beams containing a large number of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com