Machine for adhesive strip, process for adhesive strip in order to produce heat insulation and sealed wall and heat insulation and sealed wall

A technology for bonding tapes, strips, applied in the field of machines for bonding tapes, process for bonding tapes in order to produce thermally insulating and sealing walls and thermally insulating and sealing walls capable of solving monotony, surface irregularities , redundancy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

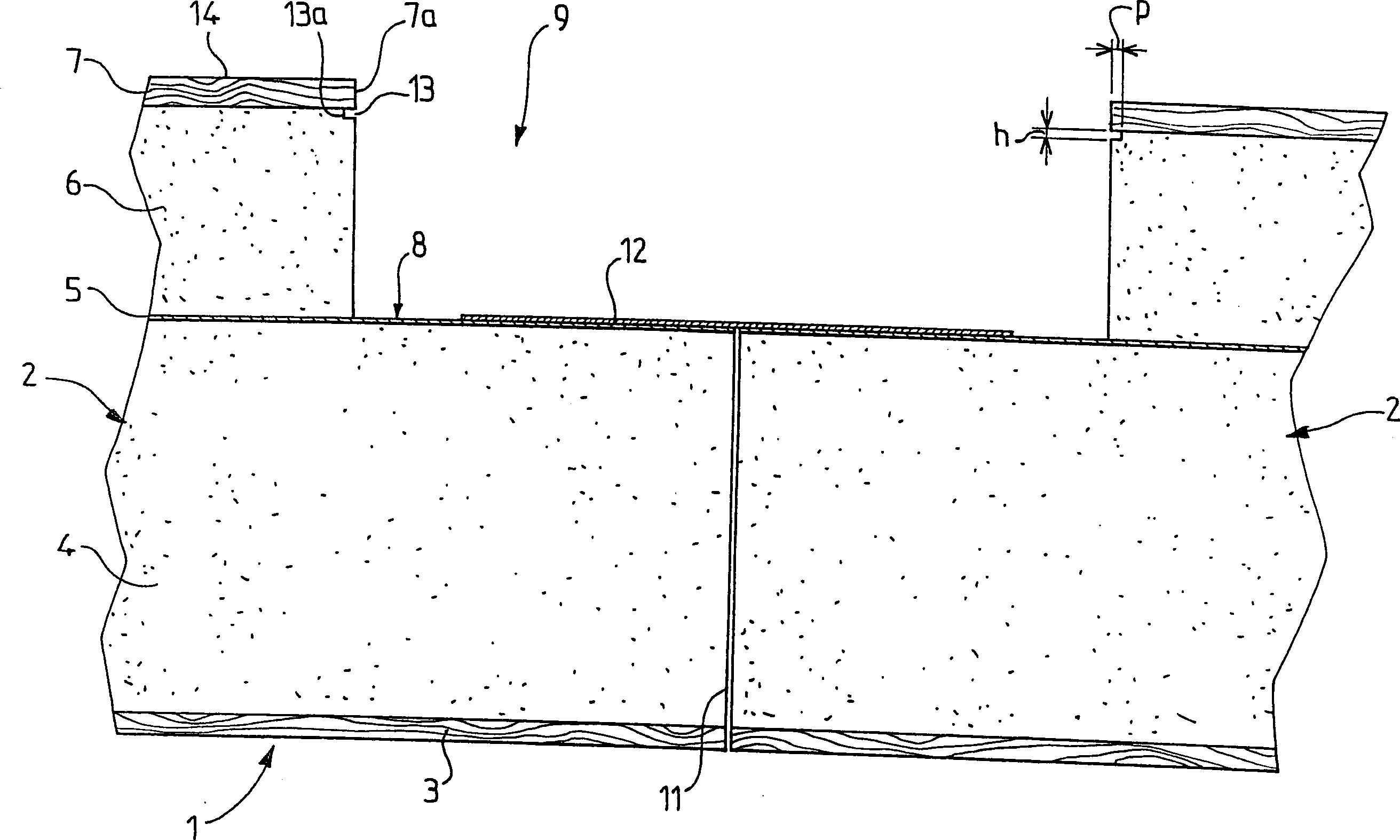

[0047] according to figure 1 , the thermally insulating and sealing wall 1 is formed by a wall panel indicated as a whole by the reference numeral 2, this wall 1 constituting a first thermally insulating barrier, a second thermally insulating barrier and a second sealing barrier. Each wall is substantially in the shape of a right-angled parallelepiped and consists of a first plywood 3 on which a first thermal insulation layer 4 is arranged, on which a layer of rigid Tempered or toughened batten 5 ; above the batten 5 is a second thermal insulation layer 6 supporting a second plywood 7 . Subparts 6, 7 constitute a first insulating barrier part that is rectangular in plan view, with sides parallel to the sides of subparts 3, 4, 5; A rectangle with the same center, a peripheral side edge 8 of fixed length surrounds the subparts 6, 7 and is formed by the edges of the subparts 3, 4, 5. The subcomponents 3, 4 constitute a second insulating barrier part. The strip 5 covering the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com