Method for detecting non-planeness defect

A technology of unevenness and detection area, which is applied in the direction of tension measurement, measuring device, electric device, etc., and can solve the problem that the unevenness measuring roller cannot be used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

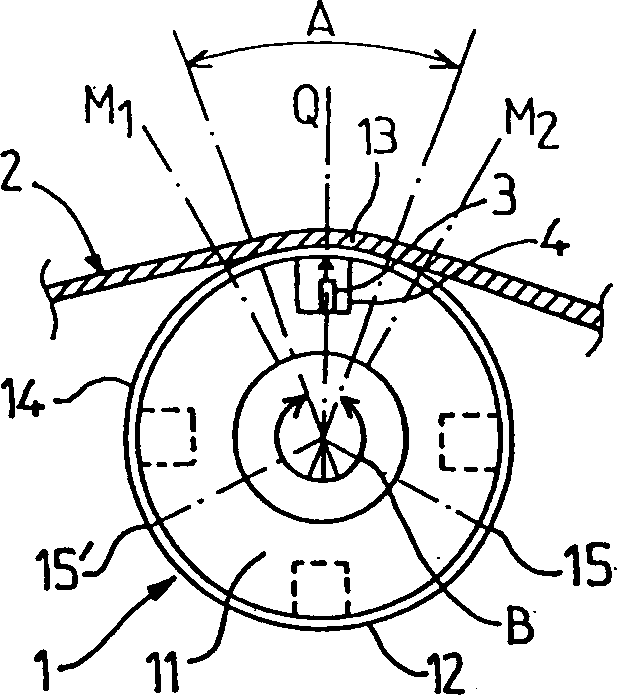

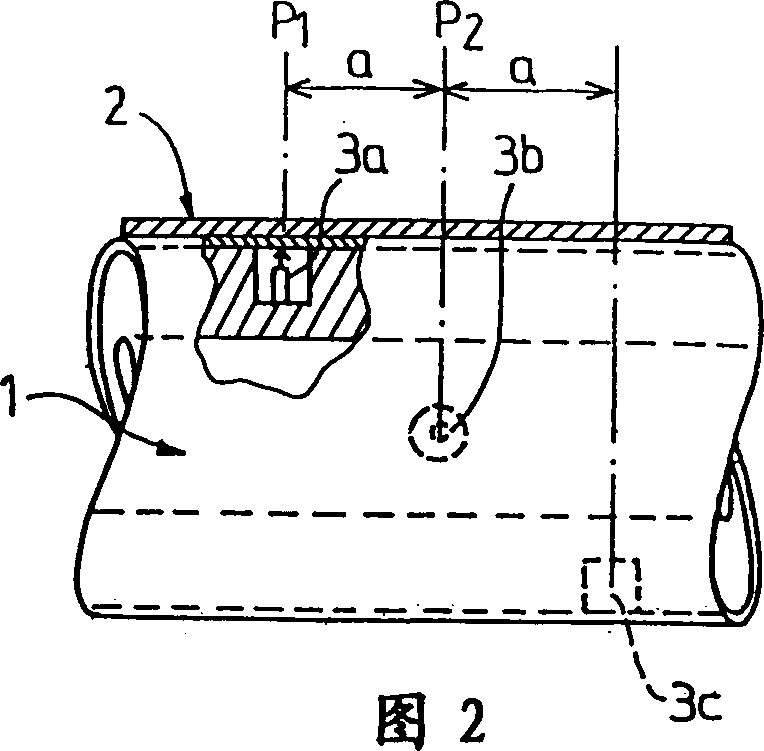

[0053] figure 1 and 2 schematically represent an unevenness measuring roll 1 to which a strip 2 is applied (applied) under tensile load, the strip 2 covering one of the angular sectors A of the roll 1 .

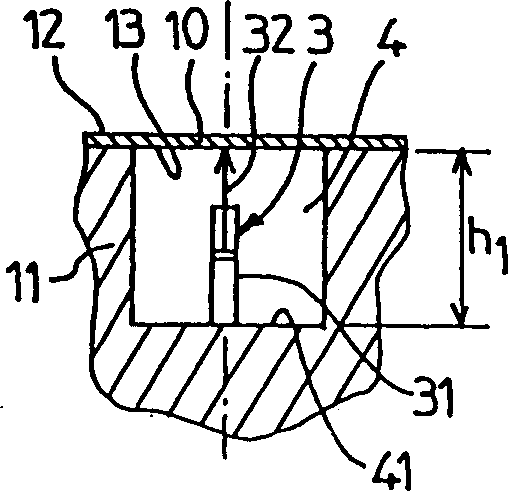

[0054] The roll 1 consists, in a known manner, of a corrosion-resistant (durable) tubular body 11 covered with a thin annular cladding 12 .

[0055] The roll 1 is equipped with a plurality of measuring sensors 3, each of which is arranged in a recess 4, for example in a blind hole drilled in the corrosion resistant body 11, and these recesses form the sensor 3 protective walls A section 10 of the thin cladding 12 is closed to the outside.

[0056] As shown in Figure 2, each sensor 3 is axially spaced apart by a pitch (a), and is distributed in a spiral shape on the entire length of the roller, so that two adjacent sensors 3a, 3b are staggered by an angle for Easier measurement handling.

[0057] All of these configurations are well known and require no elaboration.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com