Multilateral rotary regulating and shearing mechanism

A technology of rotation adjustment and shearing mechanism, which is applied in the field of plastic machinery and can solve problems such as low production efficiency, inability to adjust, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

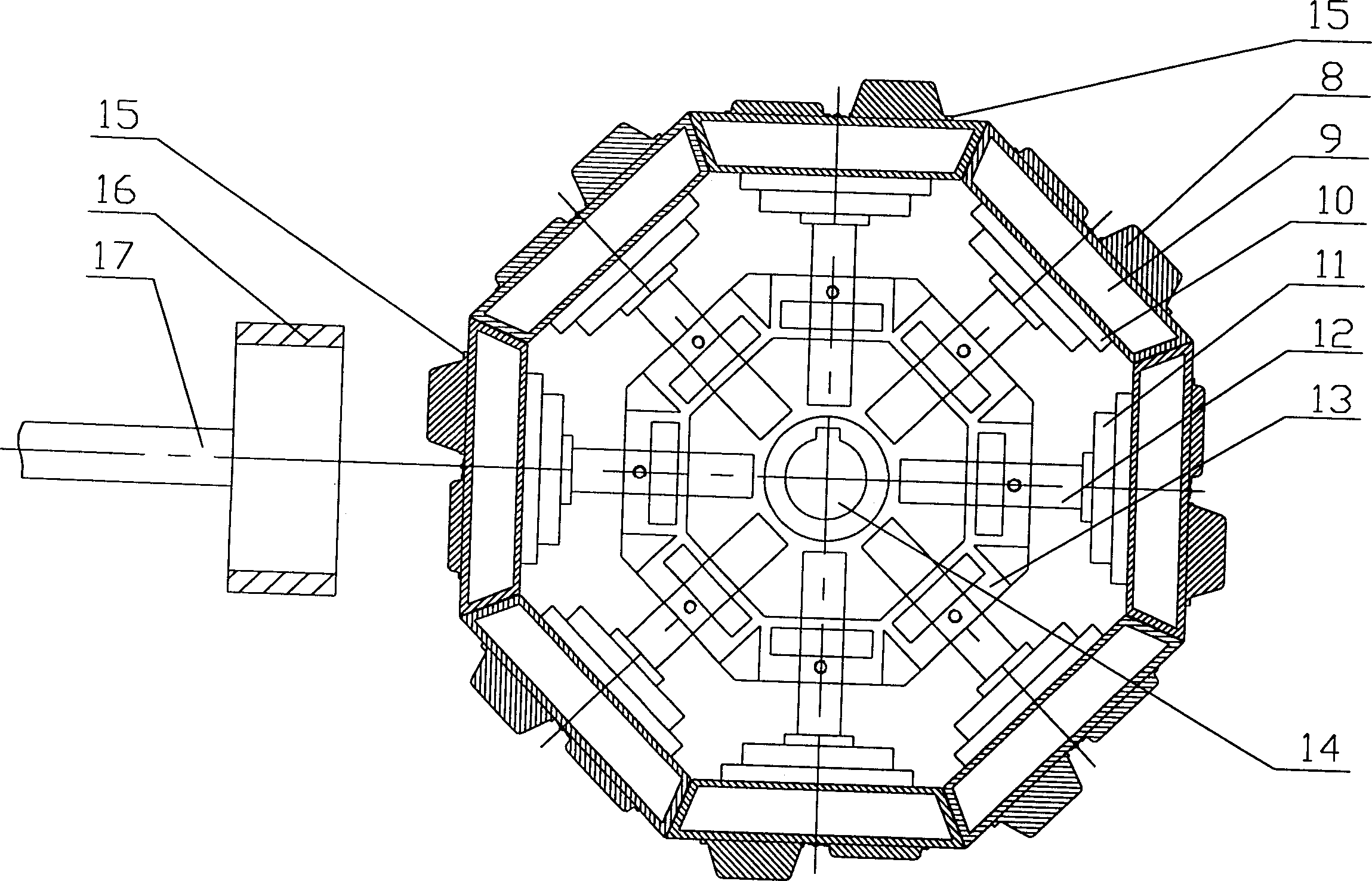

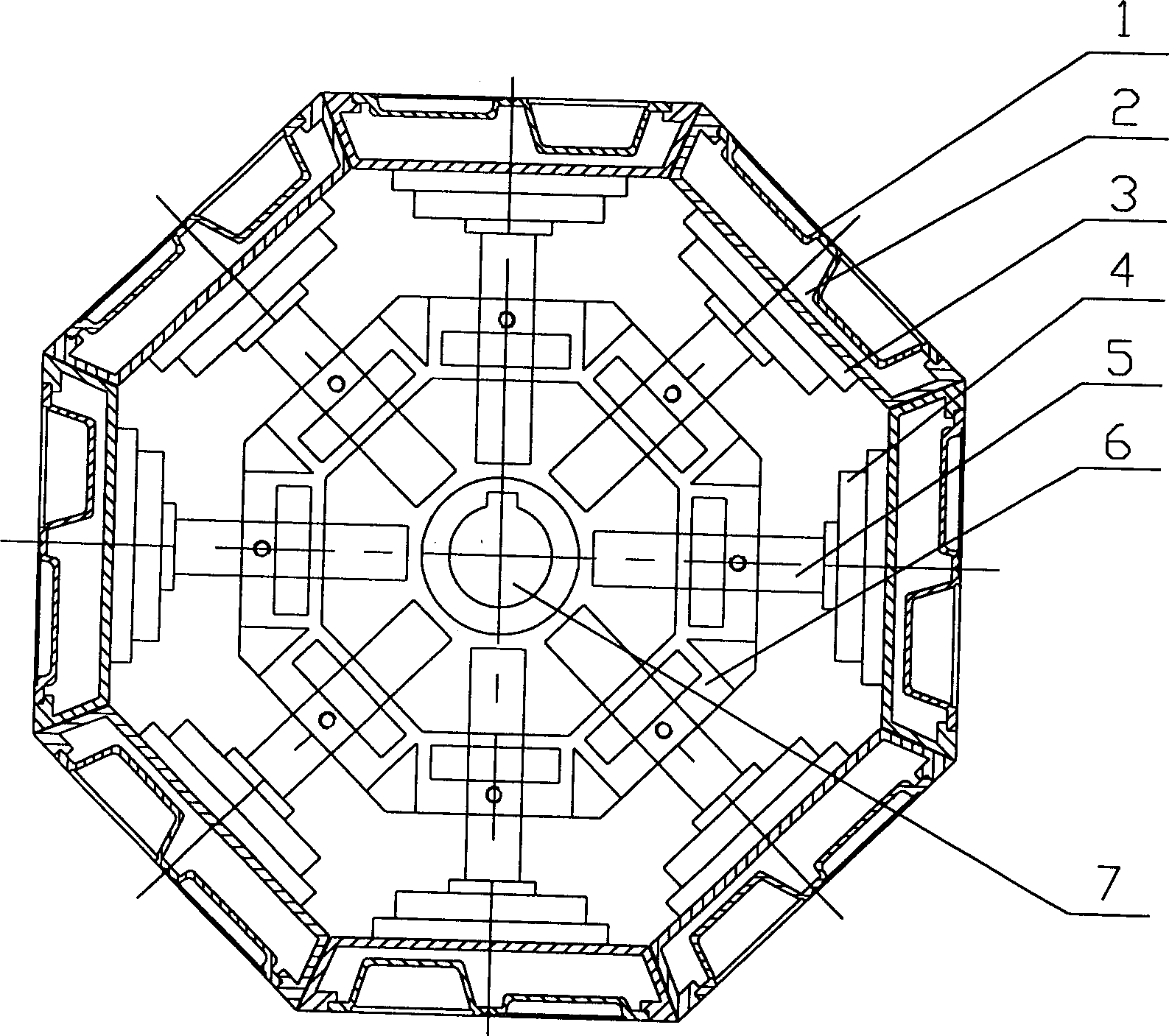

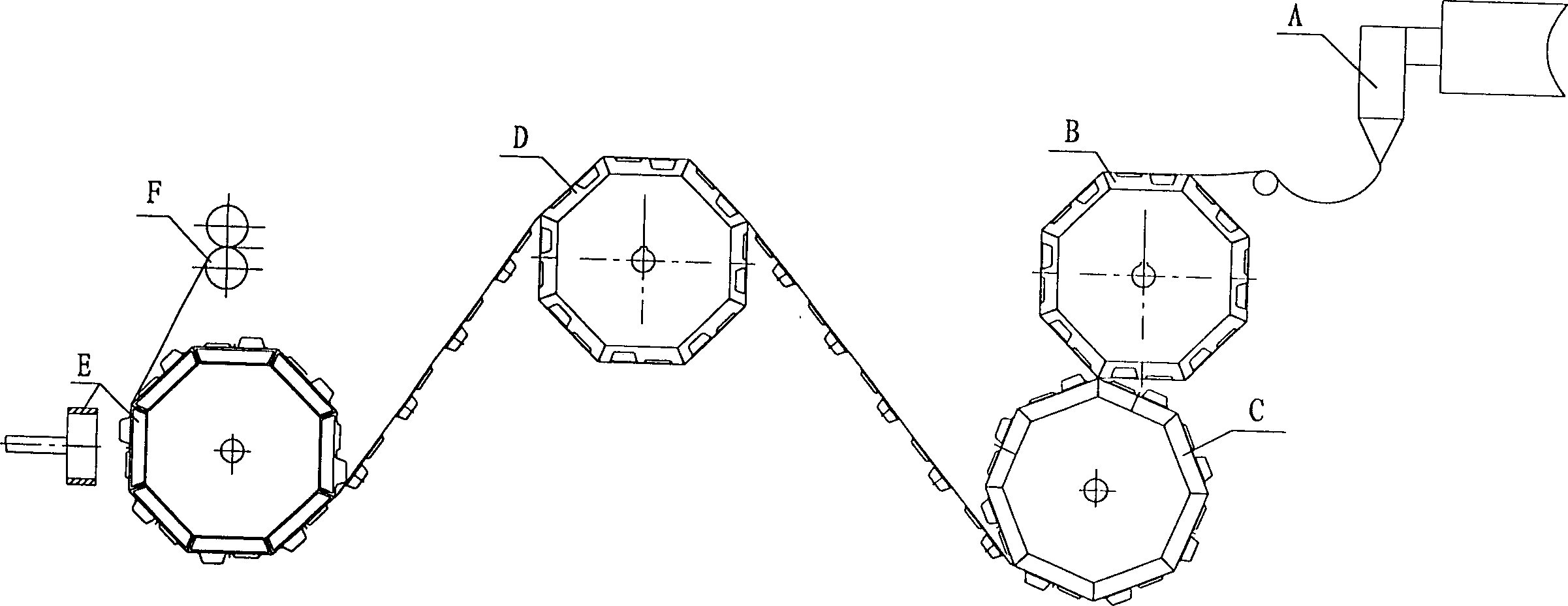

[0009] With reference to the accompanying drawings, first adjust the up and down strokes to adapt to the installation of product molds of various sizes by adjusting the adjustment screw 5 provided on the side (or surface) of the plastic suction mechanism B through the multilateral rotation. The extruder A is extruded into a sheet and enters the multilateral rotation adjustment suction mechanism B, and the multilateral rotation adjustment suction molding mechanism B is set on the side (or surface) of the suction mold 1 and the vacuum supported on the vacuum chamber frame 3. Chamber 2 uses the extrusion temperature to vacuum absorb and shape the sheet (product), adjust the rotation of the power spindle 7 in the suction mechanism B along with the multilateral rotation, and the sheet (product) after adsorption and molding enters the cooling and shaping conversion mechanism C for cooling and shaping At the same time, the multi-lateral rotation adjustment on another side (or surface)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com