Full-automatic control method using fuzzy control for temp of polymerizing reactor

A technology of fuzzy control and control method, applied in the direction of temperature control, program control, computer control, etc., can solve the problems of unstable product quality, high labor intensity of workers, difficult control of kettle temperature, etc., to improve the level of production automation and eliminate waste. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

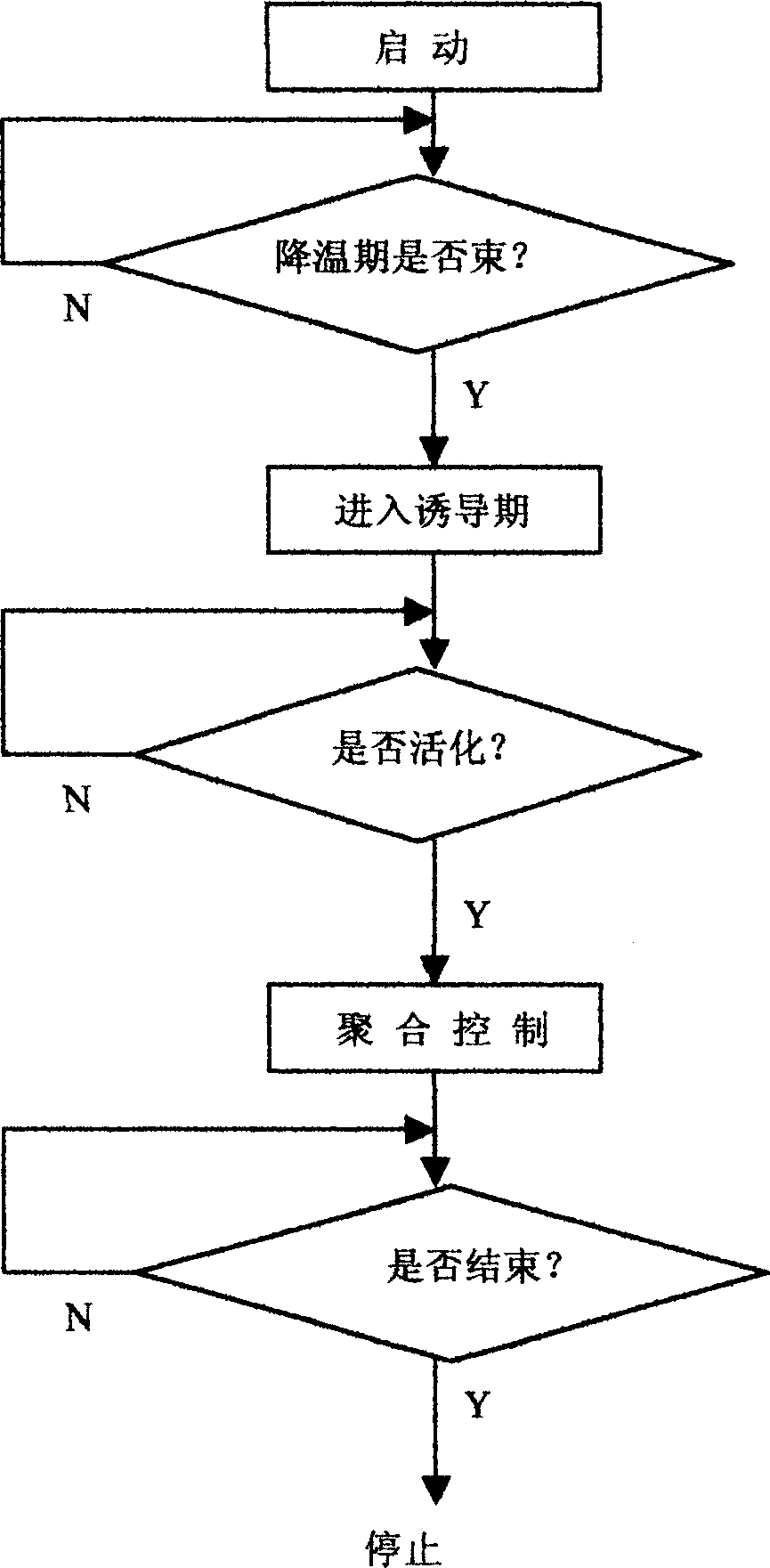

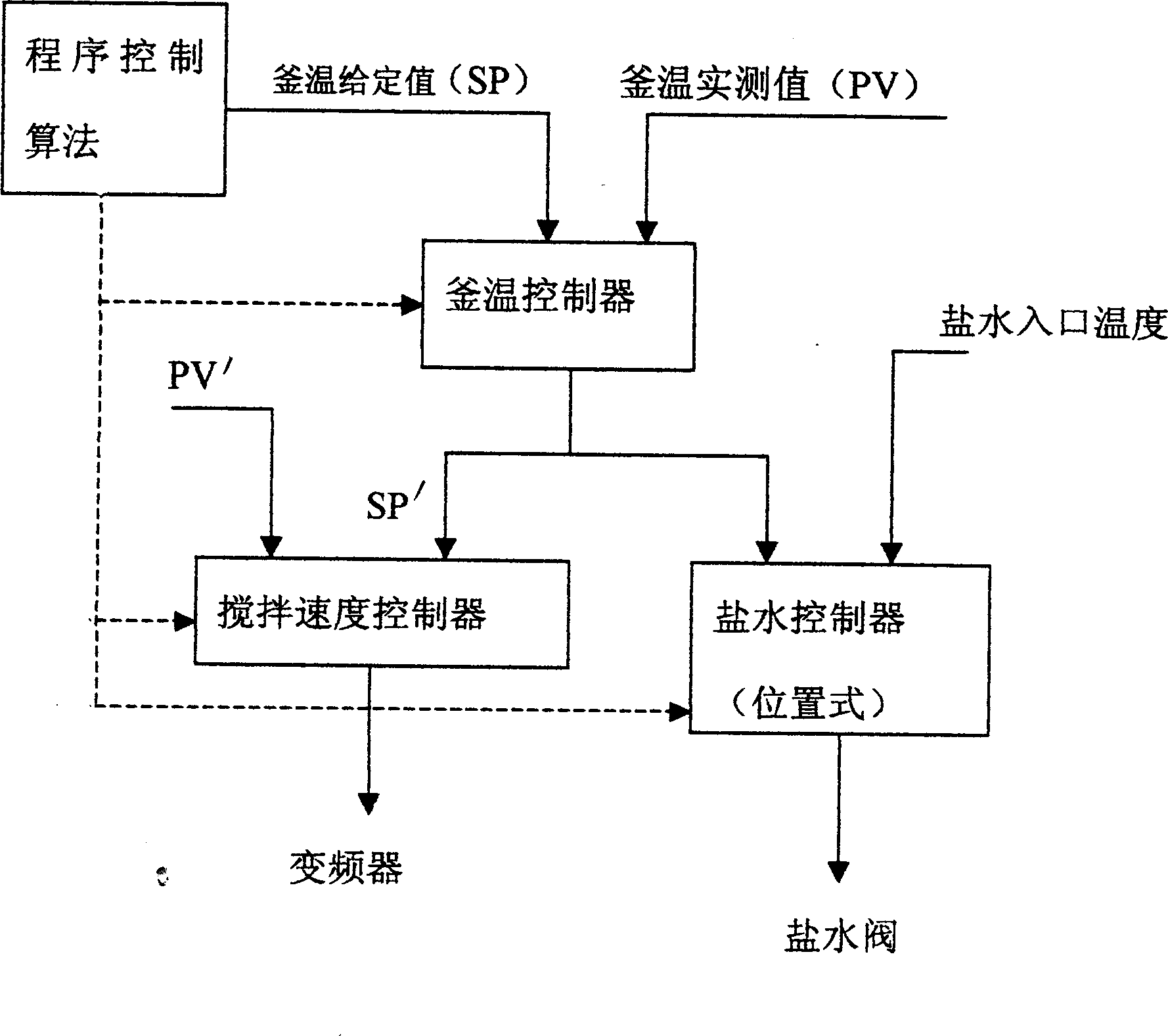

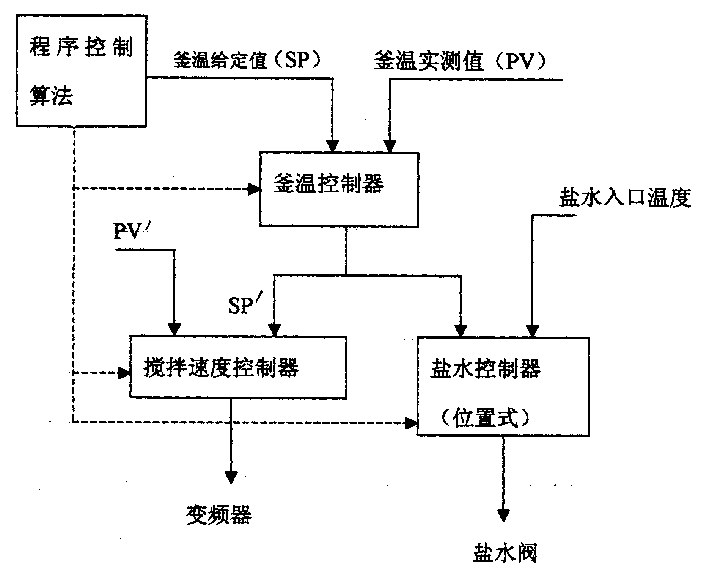

[0018] see figure 1 with figure 2 . Set up kettle temperature controller, stirring speed controller and brine controller in programmable logic controller (PLC machine),

[0019] Use the following methods to control the temperature of the polymerization tank, the stirrer and the flow of brine:

[0020] 1. Set the expected value SP of the kettle temperature in the kettle temperature controller and compare the actual measured value of the kettle temperature PV to obtain the kettle temperature deviation FE. The input language variables are the kettle temperature deviation FE and the kettle temperature deviation change rate DFE, and the output The linguistic variable is the output increment ΔU, where

[0021] FE=PV-SP, PV is the actual measured value, SP is the set value DFE = FE 2 - FE 1 T , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com