Connector

A connector and connector technology, applied in the direction of connection, conductive connection, fixed connection, etc., can solve the problems of troublesome handling, difficult cover placement, and ineffective installation work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

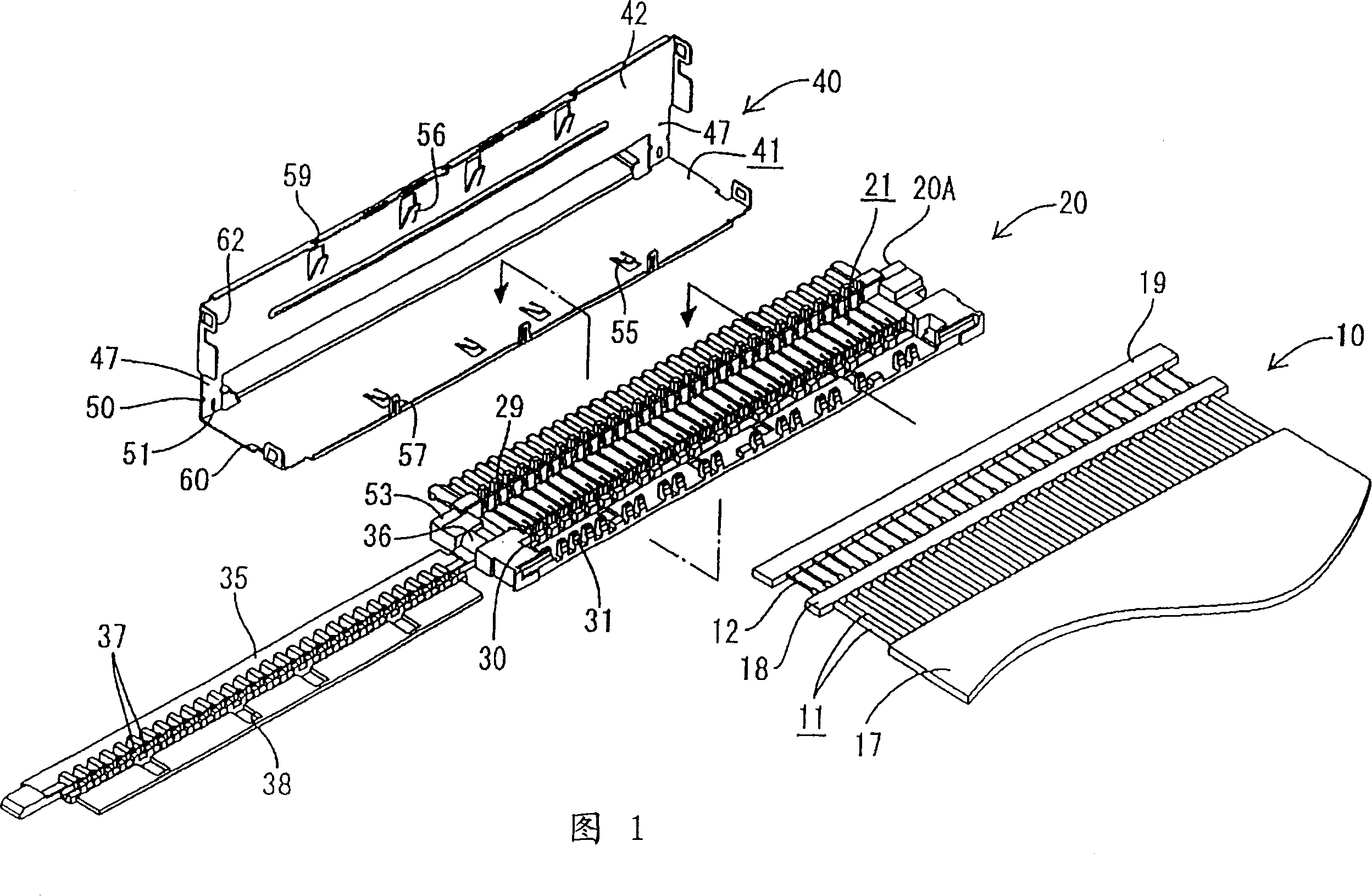

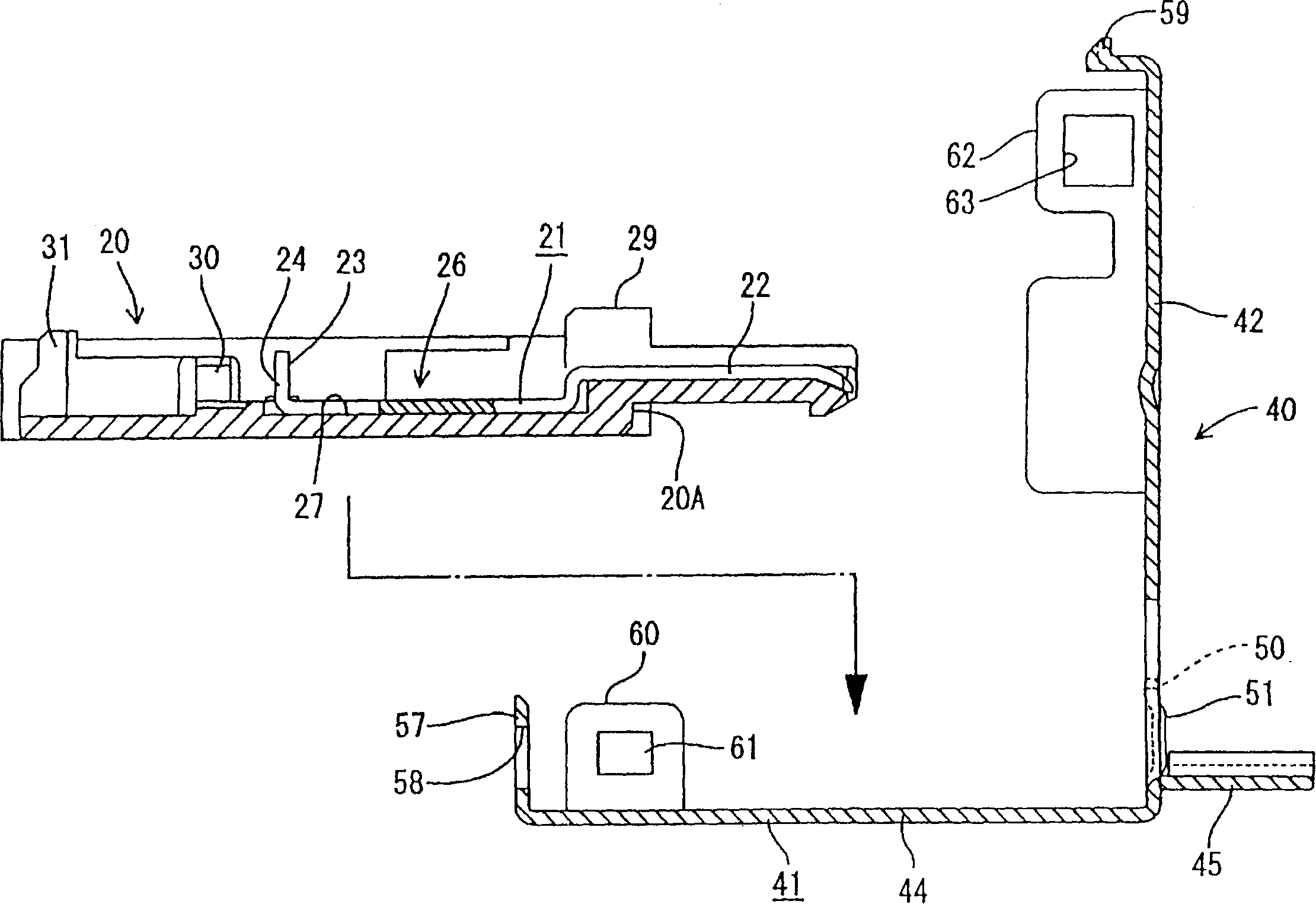

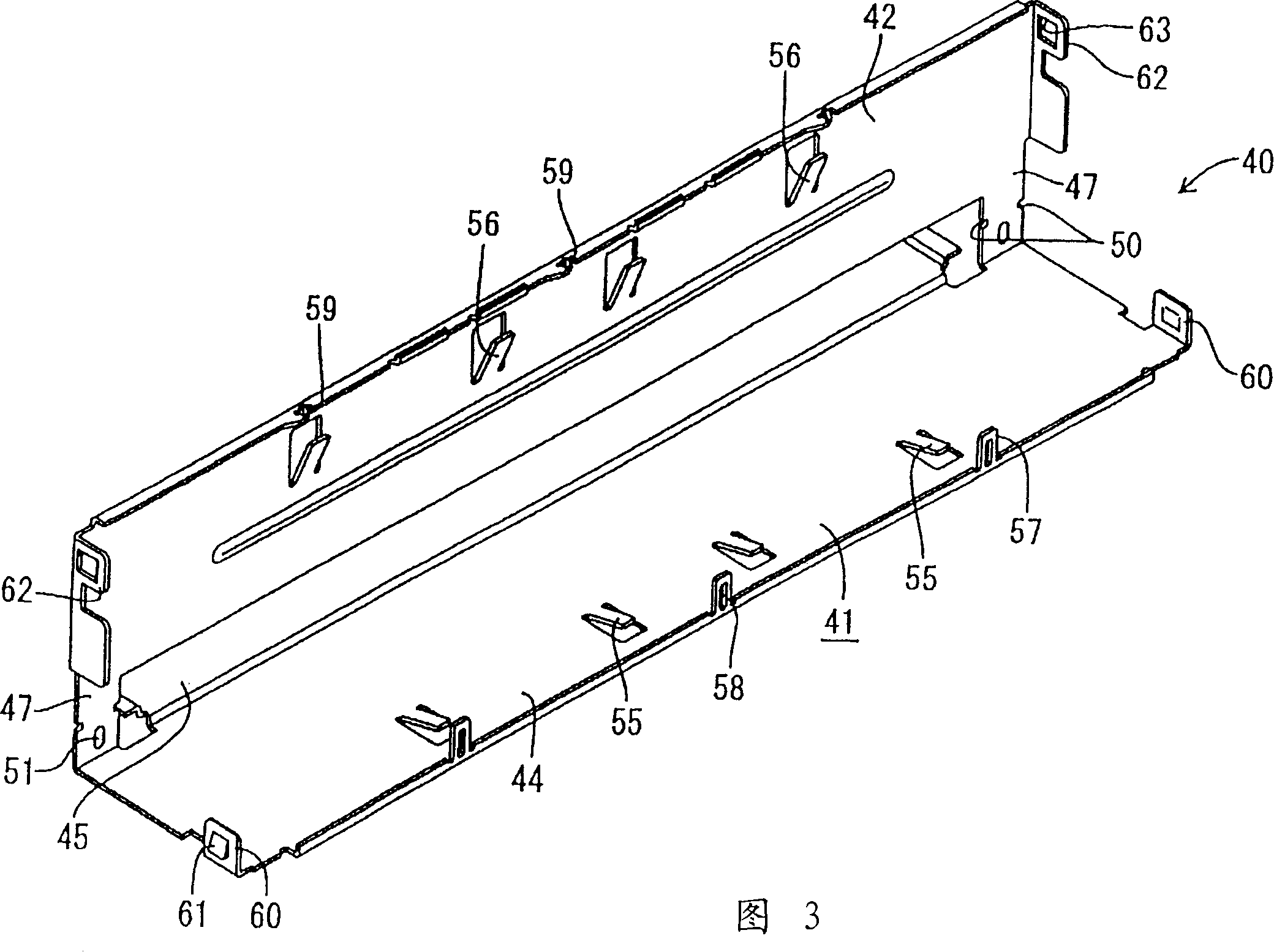

[0039] A first embodiment of the flat cable connector of the present invention will be described below with reference to FIGS. 1-11.

[0040] As shown in FIG. 1 , the connector in this embodiment basically includes a housing 20 to be connected to the end of the flat cable 10 and a shield shell 40 to be mounted to the housing 20 .

[0041] Such as Figure 6 As shown, the flat cable 10 includes a plurality of parallel shielded wires 11 spaced apart from each other by a predetermined distance. Each shielded wire 11 has a core wire 12 , an inner coating layer 13 surrounding the core wire 12 , a shielding layer 14 surrounding the inner coating layer 13 and an outer coating layer 15 surrounding the shielding layer 14 . A film 17 covers these wires 11 to form a ribbon-like structure. A short-circuit element 18 is fixed on the shielding layer 14 of each shielded wire 11 at the end of the flat cable 10 . The core wire 12 of each shielded electric wire 11 is exposed on the front side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com