Process for preparing shallow-channel isolating structure

A technology of isolation structure and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve problems such as affecting production volume, reducing productivity, and slow deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

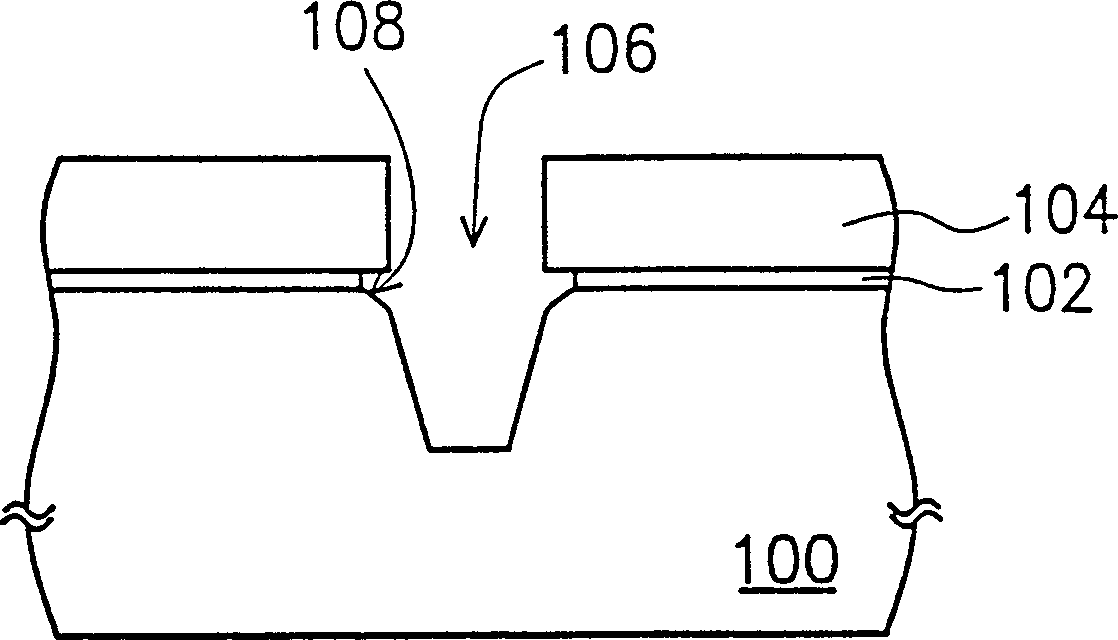

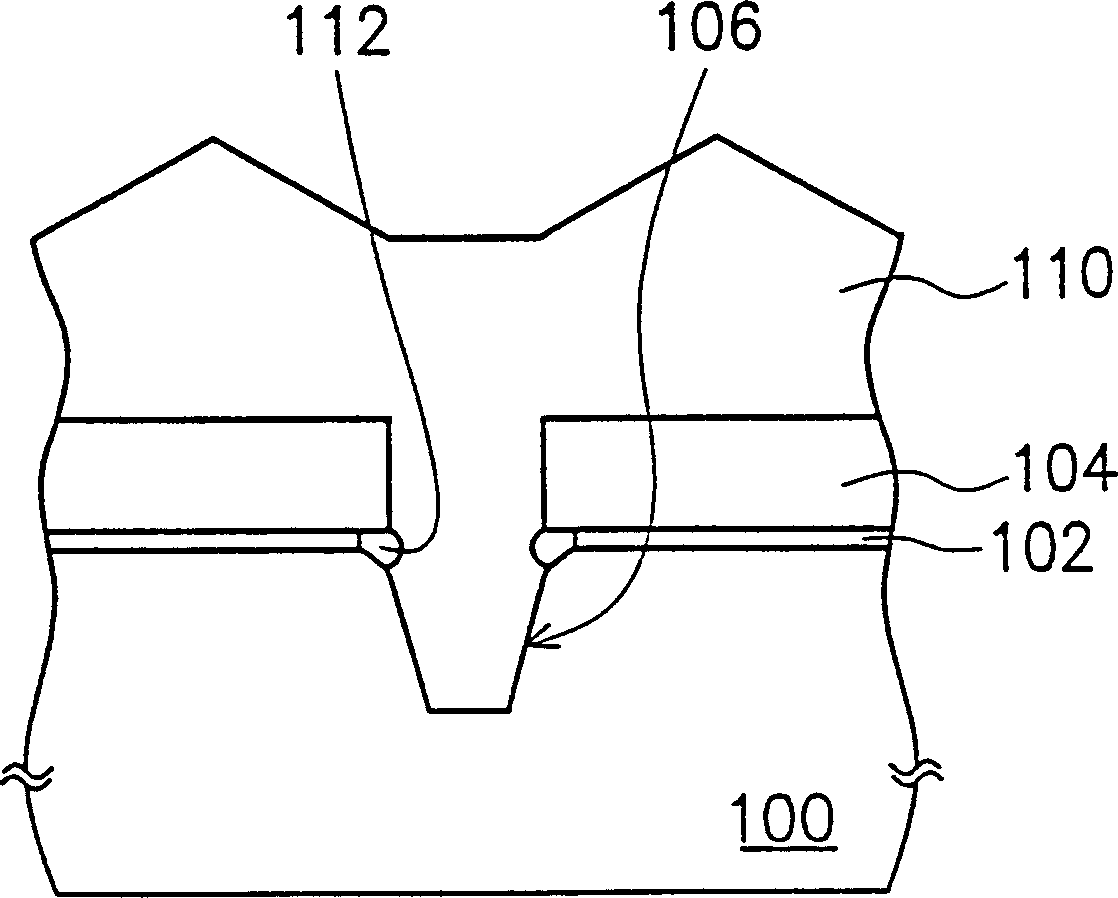

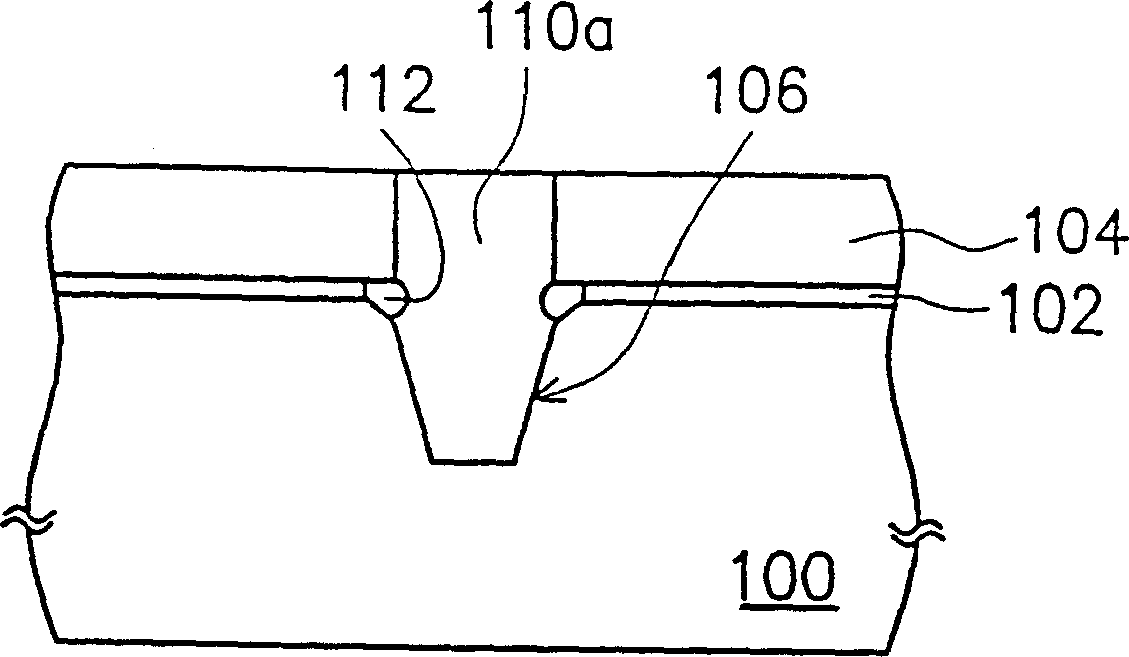

[0036] Figure 2A to Figure 2E It is a schematic cross-sectional view of a manufacturing process of a shallow trench isolation structure according to an embodiment of the present invention.

[0037] First, please refer to Figure 2A 1. A substrate 200 is provided, and a pad oxide layer 202 is formed on the substrate 200, wherein the material of the pad oxide layer 202 is, for example, silicon oxide; the forming method is, for example, a thermal oxidation method. Next, a mask layer 204 is formed on the pad oxide layer 202 . The material of the mask layer 204 is, for example, silicon nitride; the method of forming the mask layer 204 is, for example, chemical vapor deposition.

[0038] Next, please refer to Figure 2B , removing part of the mask layer 204 , the pad oxide layer 202 and the substrate 200 to form the trench 206 . The method for forming the trench 206 is, for example, forming a patterned photoresist layer (not shown) on the mask layer 204 . Then, using the photo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com