Angular rate sensor

A technology of angular velocity sensor and resonator, applied in the direction of gyro effect for speed measurement, instrument, speed/acceleration/shock measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

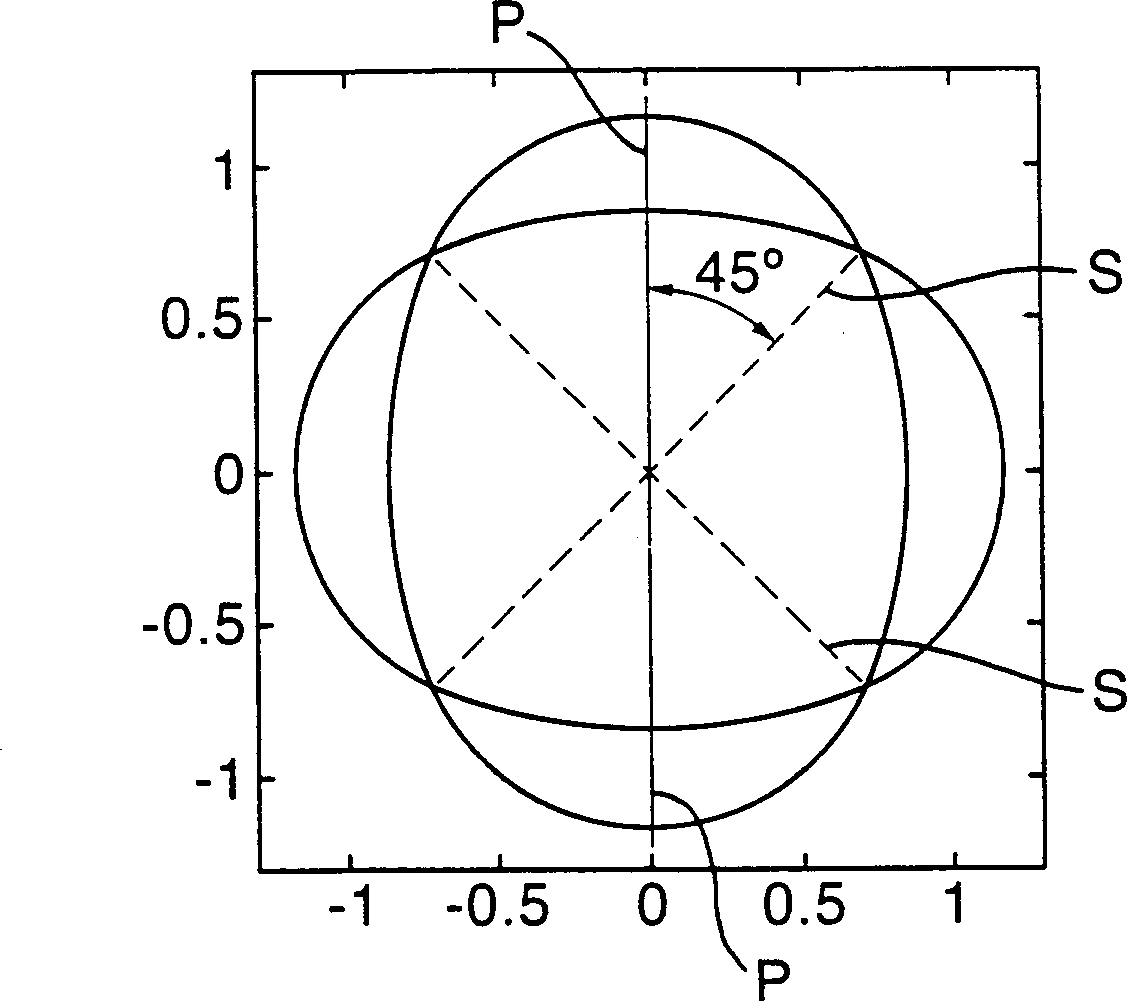

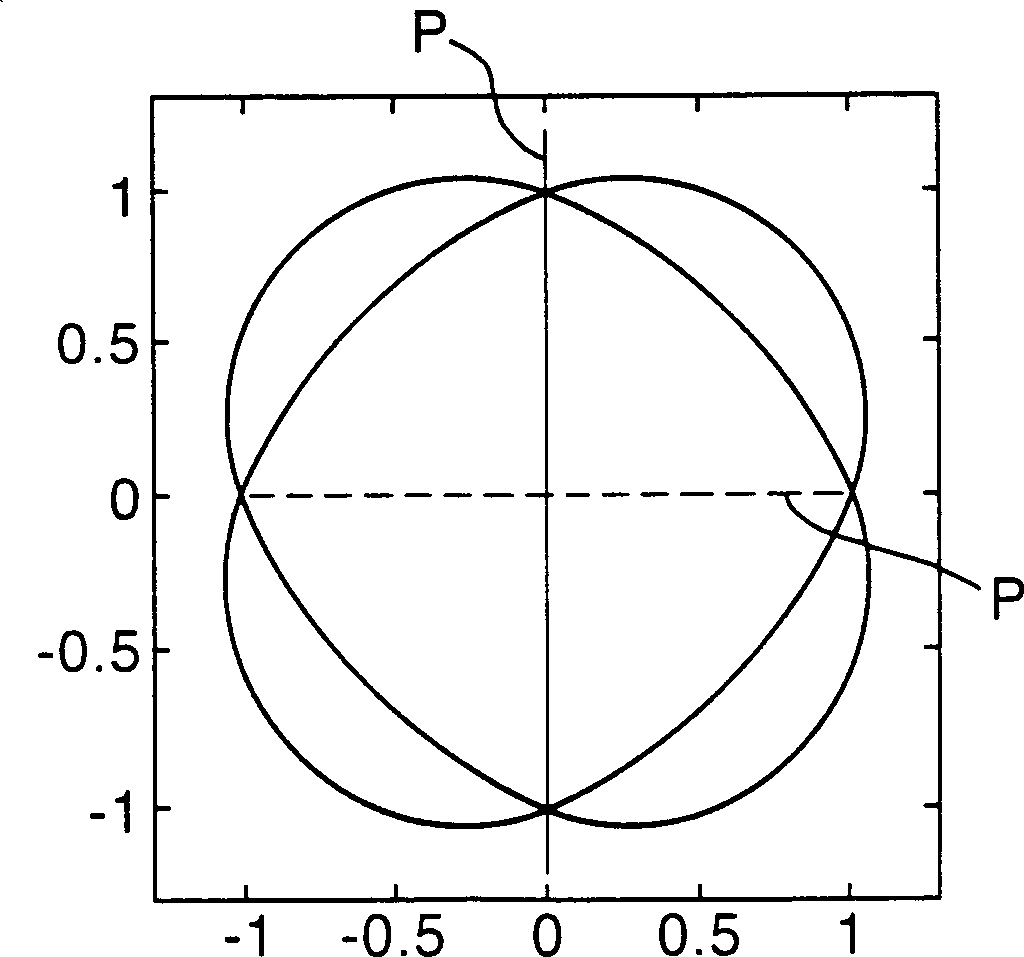

[0029] An angular velocity sensor device embodying the present invention will now be described with reference to FIGS. 3a , 3b , 4 and 5 . The sensor device 10 comprises a micromachined vibrating structure gyroscope and is arranged to operate in the Sin3Θ and Cos3Θ vibrational mode pairs as described above. More specifically, Cos 3θ carrier and Sin 3θ response pattern patterns are shown in Figures 3a and 3b.

[0030] The device 10 utilizing these modes incorporates electrostatic and capacitive drive transducers similar to those described in GB9817347.9. The manufacturing process used to produce this structure is basically the same as that described in GB9828478.9, so it will not be repeated below.

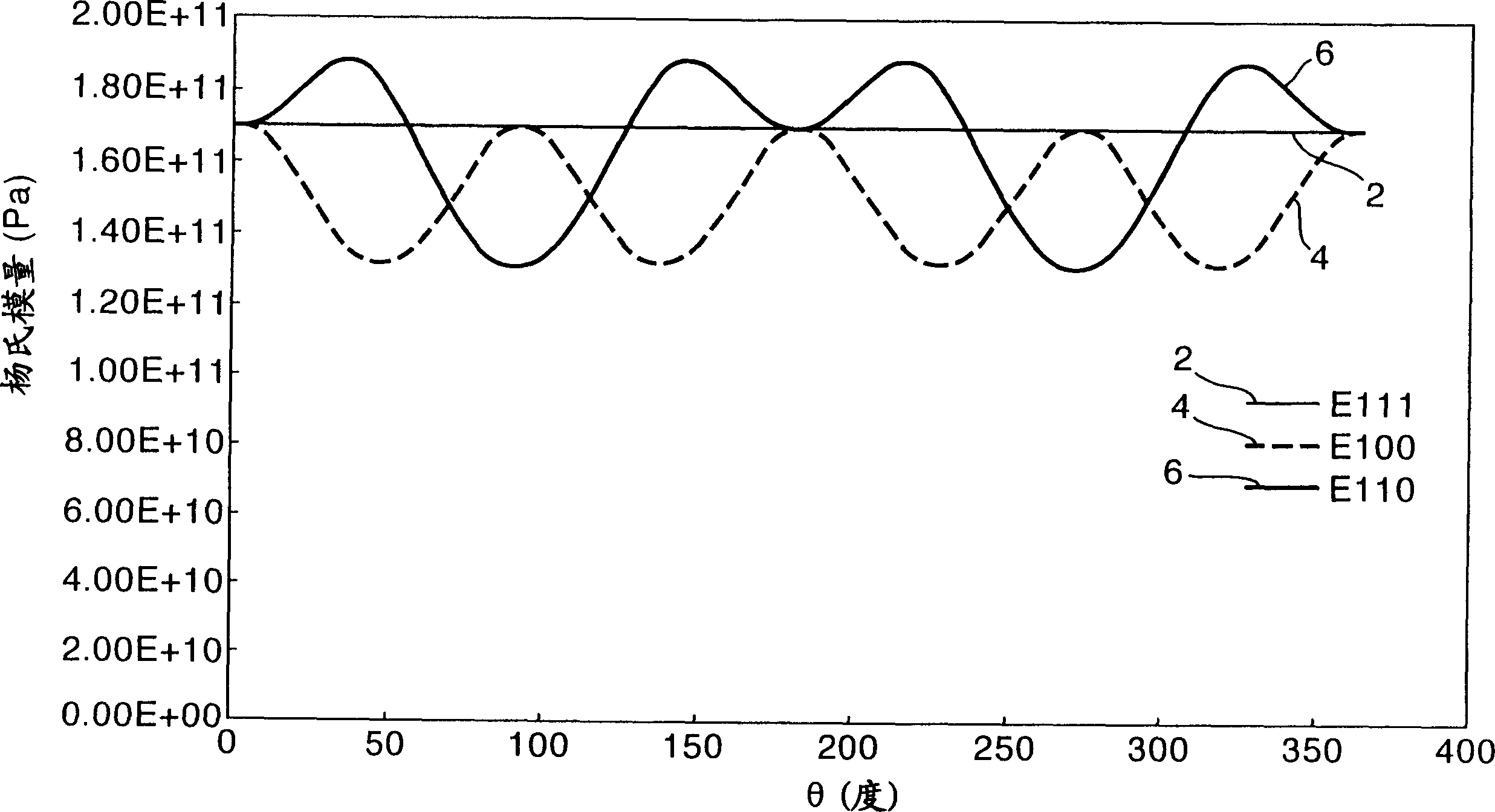

[0031] Device 10 is formed from a layer of [100] conductive silicon wafer 12 anodically bonded to a glass substrate 14 . The main components of the device 10 are the ring structure resonator 16 , six drive capacitive transducers 18 and six sensor capacitive transducers 20 . The re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com