Loom transmission

A transmission device and loom technology, applied in looms, textiles, textiles and papermaking, etc., can solve problems such as high price of brakes and clutches, reduced performance of looms, and easy wear and tear, and achieve optimal matching timing, simple structure, The effect of short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

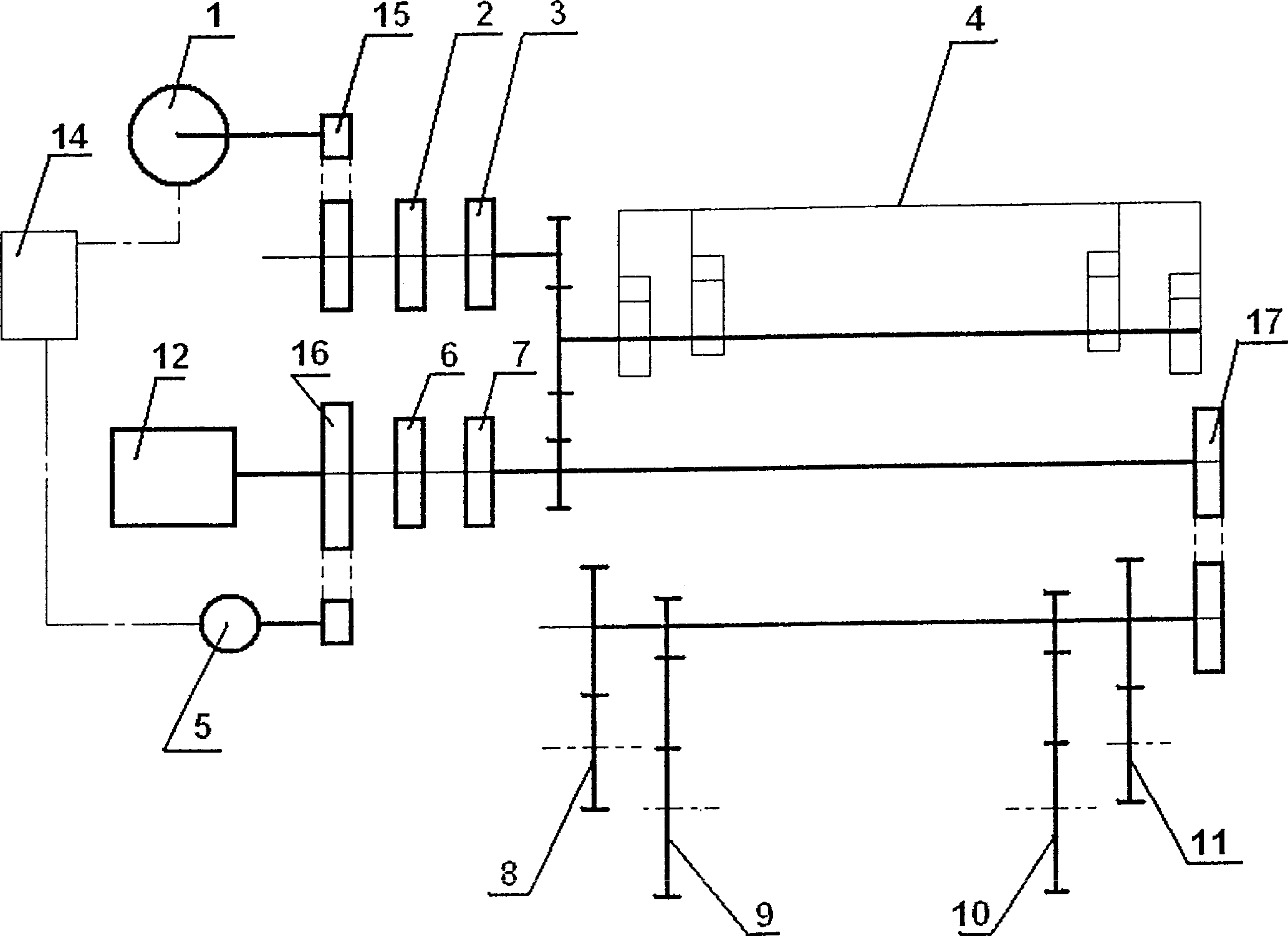

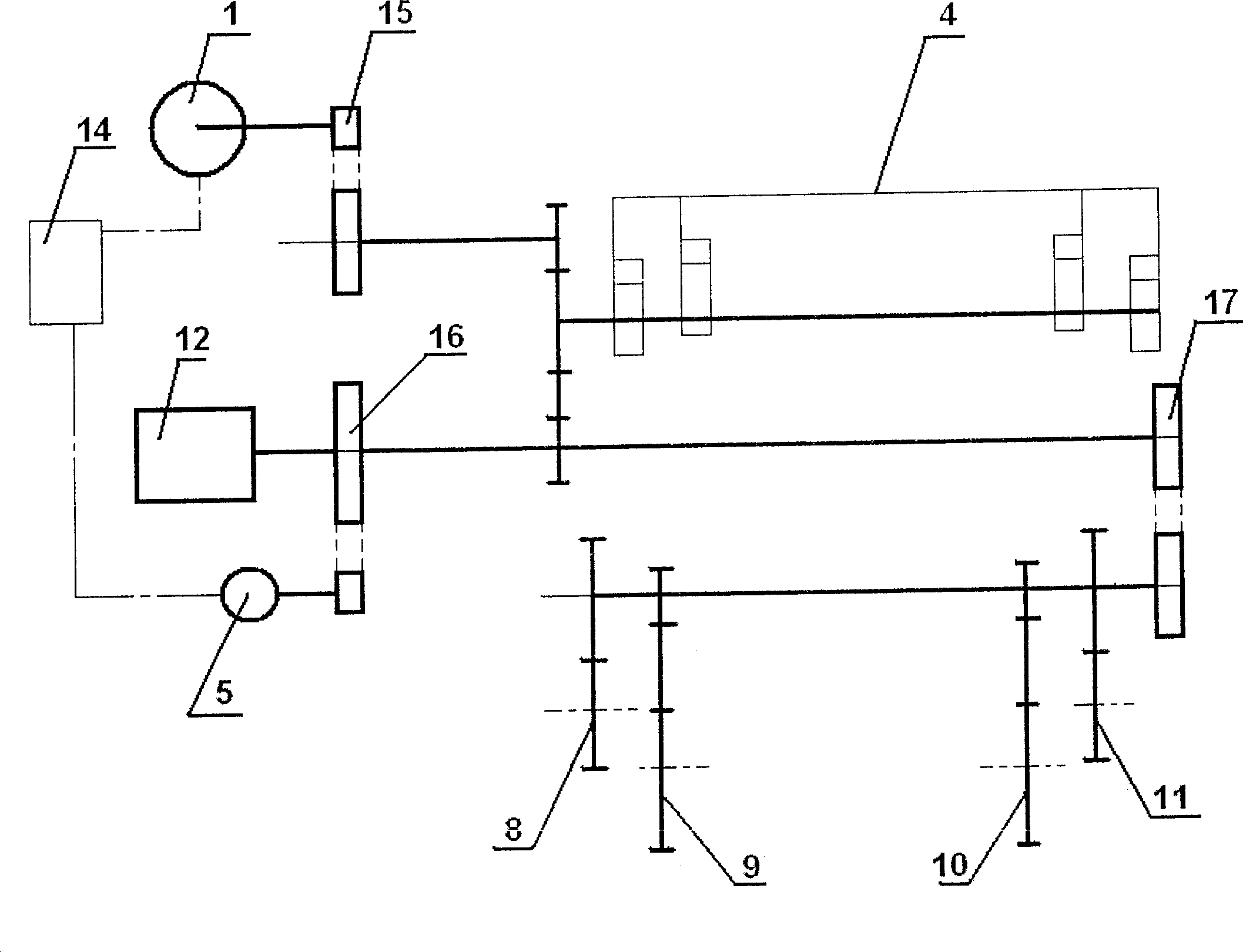

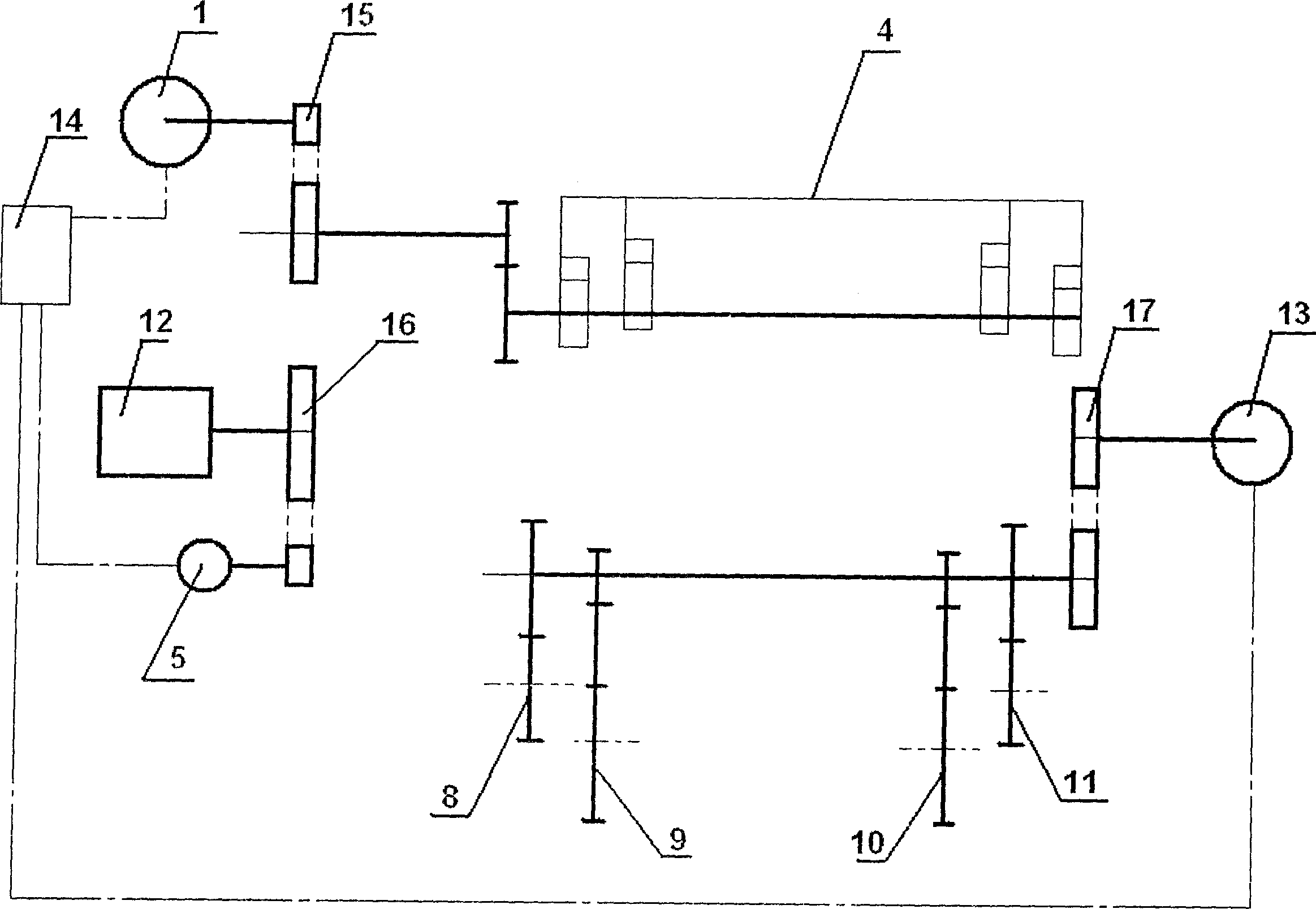

[0009] like figure 1 Shown, will usually clutch 2 in the loom transmission, after brake 3, mechanical linkage (ZX, ZY), weft-seeking clutch 6, slow clutch 7 are removed, change the hardware and the program of controller 14. The motions of the beating-up motor 1 and the shedding motor 5 are changed from the original mechanical synchronization to the electrical control synchronization of the controller 14 to meet the weaving performance of the loom. like figure 2 transmission shown. A kind of loom transmission device, it comprises beating-up motor 1, shedding motor 5, beating-up mechanism 4, shedding mechanism 12, back beam swing mechanism 8,11, hemming mechanism 9,10 and controller 14, and beating-up motor 1 passes The speed changer 15 is connected with the beating-up mechanism 4, the shedding motor 5 is connected with the shedding mechanism 12 by the speed changer 16, the speed changer 16 is connected with the speed changer 17, the speed changer 17 is connected with the bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com