Failure detecting device and method for automobile damper

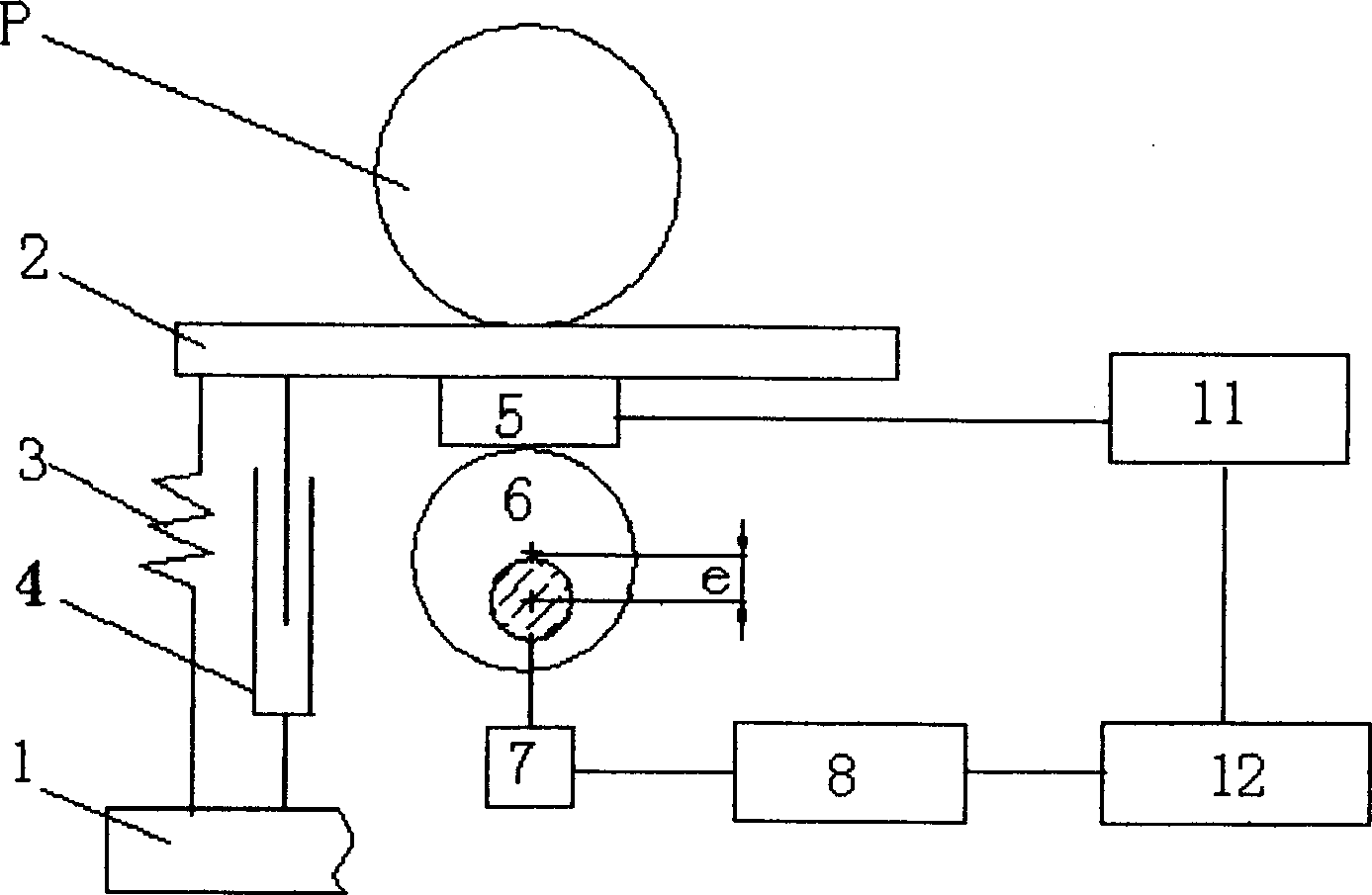

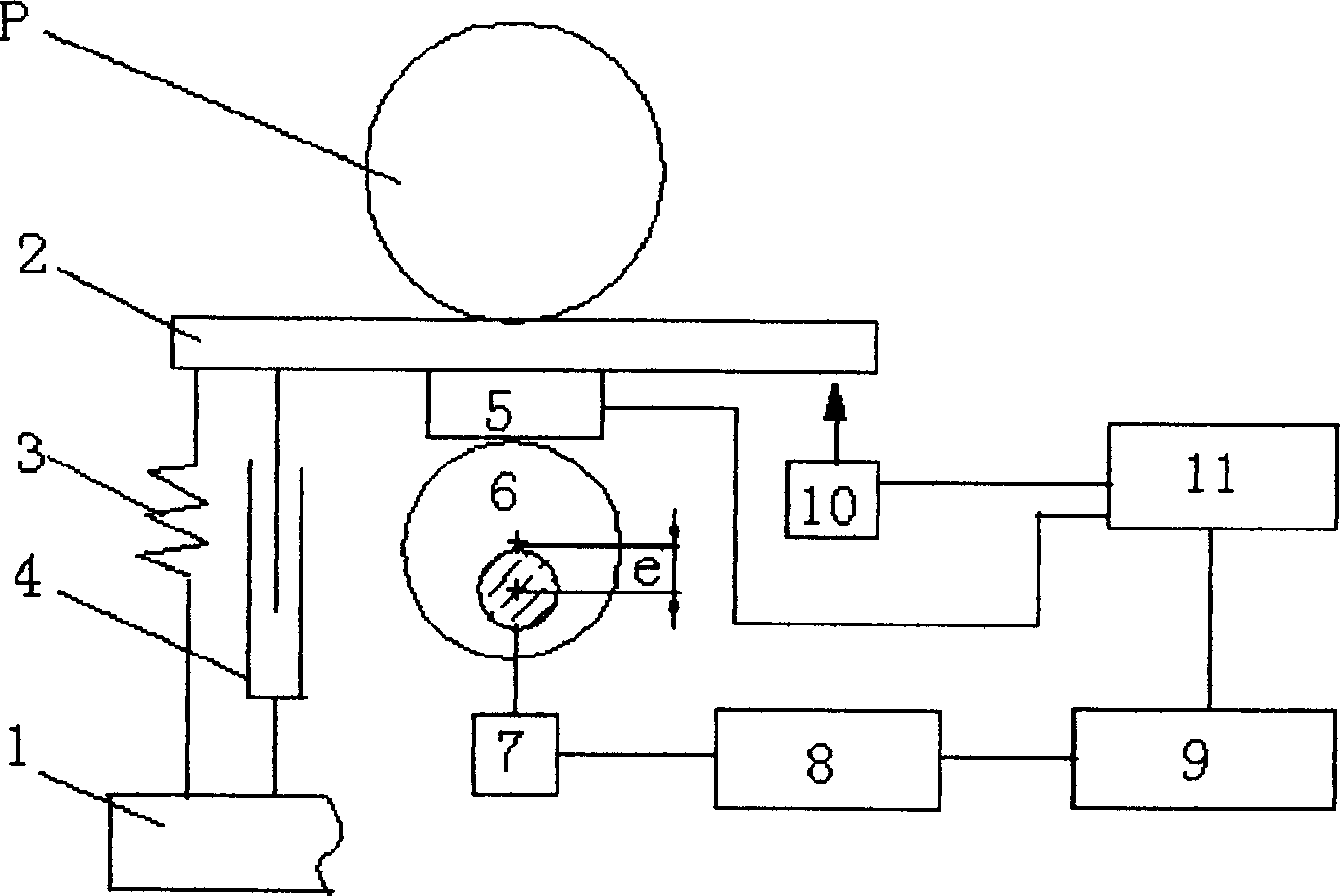

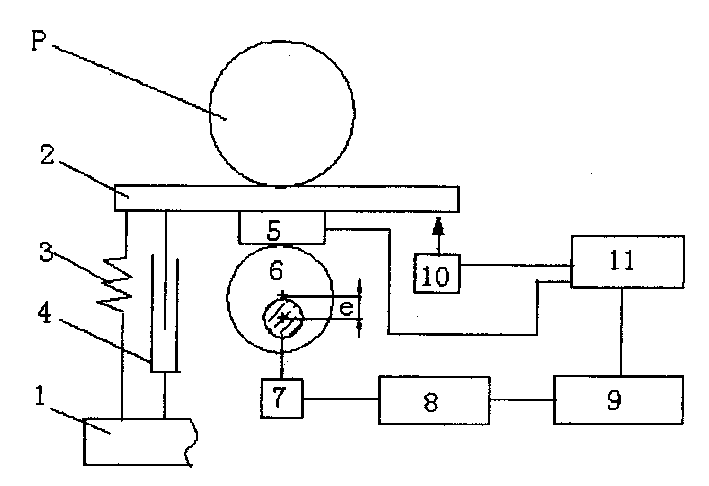

A fault test and shock absorber technology, applied in the automotive field, can solve the problems of the influence of the test results of the machining error of the eccentric wheel 6, the lack of displacement sensors, and the influence of the accuracy of the test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Embodiment: 1) test vehicle type: common Santana, the eccentric distance e of the eccentric wheel 6 of test bench selects following size for use: 2.0mm, 2.5mm, 3.0mm, 3.5mm, 4.0mm, use prior art and test result of the present invention respectively For comparison, see Table 2 below. As can be seen from Table 2, the machining accuracy of the eccentric wheel of the present invention has substantially no influence on the test results.

[0026] this invention

Eccentric distance emm

Adhesion percentage A

Adhesion percentage A

2

63.5

0.32

76.4

2.5

64.2

0.30

70.5

3

63.9

0.31

64.6

3.5

63.1

0.31

58.7

4

64.5

0.31

52.8

[0027] 2) test vehicle type: common Santana, as can be seen from Table 3, under the test condition of serial numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com