Metal halide lamp

A metal halide lamp and halide technology, applied in the field of light-emitting tubes, can solve the problems of reduced beam maintenance rate and large change of lamp color temperature, and achieve the effect of improving color temperature drop and high light color temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

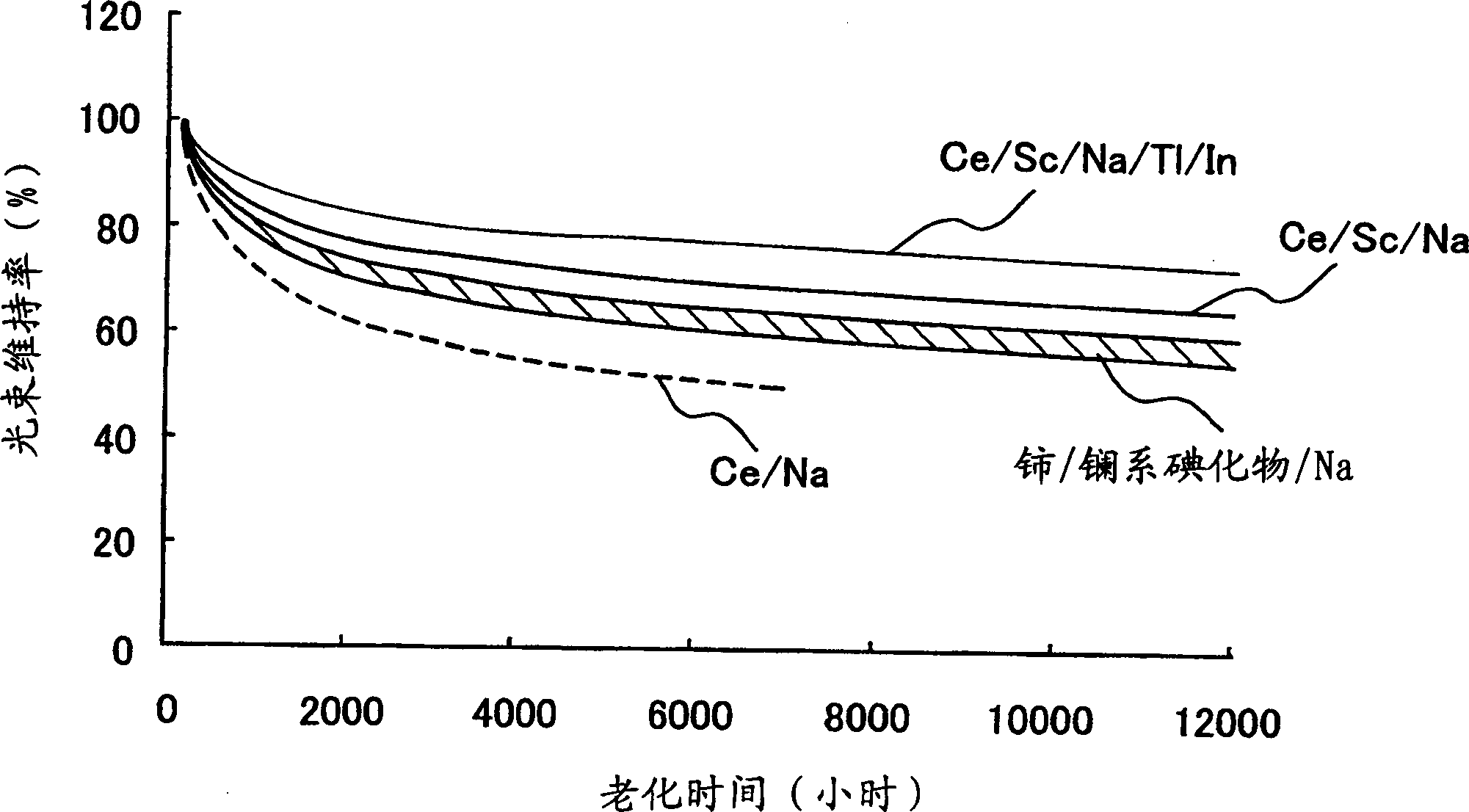

[0029] Prepare the lamp 18 that luminous tube 1 forms, and this luminous tube adopts CeI 3 : 35wt% (14mol%), NaI: 60wt% (83.5mol%), Scl 3 : 6 mg of a substance having a composition of 5 wt % (2.5 mol %) was encapsulated as a luminescent substance 17, and lifetime characteristics related to aging were studied. The result is as image 3 As shown by the line of Ce / Sc / Na, the beam maintenance of the lamp is greatly improved to 65% at an aging time of about 12000 hours. Moreover, the color temperature change during aging is within -150K, which is better than that without ScI 3 Good times.

[0030] Then, in the analysis of the lamp after 5000 hours of the same aging time as above, it was found that the CeI in the tube 3 There is still enough remnants of 80-90% of the original enclosed volume, on the other hand ScI 3 It reacts more with alumina ceramics, and only 20-30% remains.

[0031] Moreover, the initial lamp characteristics of the lamp 18 of this embodiment are maintained...

Embodiment 2

[0043] Under the same conditions as in Example 1, when CeI 3 When it is 100 mole parts, change scandium iodide ScI in the range of 0-200 mole parts 3 The encapsulation amount of the lamp is carried out to carry out the aging test of the lamp. The results show that when scandium iodide ScI 3 When the encapsulation amount of Tungsten exceeds 100 mole parts, the tungsten electrodes 6 and 7 are deformed and worn out, and the luminous tube is blackened, thereby decreasing the luminous flux maintenance ratio on the contrary. Moreover, iodide ScI 3 The effect of inhibiting the halide reaction of aluminum oxide and cerium is not clearly observed when the amount of the compound contained is less than 1.5 mole parts.

[0044] According to the test results, when CeI 3 When it is 100 mole parts, scandium iodide ScI is preferred 3 The effective enclosing amount is in the range of 1.5-100 mole parts. In this case, enclosing ScI 3 In lamps with 150 mole parts or more, a trace amount o...

Embodiment 3

[0052] Next, as a study related to the above-mentioned analysis (b), a means for suppressing the shrinkage and bending of the discharge arc generated by the cerium halide luminescent substance of the above-mentioned prior art and improving the light beam maintenance ratio is searched for. As a further goal it is possible to increase the means of lamp efficiency. As a result, it was found that especially as a luminescent substance, it is effective to re-enclose with a combination of TlX, a halide of thallium, and InX, a halide of indium.

[0053] Specifically, the above-mentioned (CeI3+NaI+ScI3) of the present invention was prepared in which TlI and InI whose composition was changed in the range of 0 to 10 wt% were also enclosed in the lamp 18, and its initial characteristics and aging-related light beam maintenance were measured. Rate.

[0054] As a result, it was observed that basically the encapsulation of TlI and InI broadened the discharge arc and suppressed the bending o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com