Electric heater of vehicle hook of middle buffer vehicle hook

A technology of electric heaters and buffer couplers, applied in electric heating devices, railway vehicle coupling accessories, electrical components, etc., can solve the problems of mechanical damage to the heating body, overheating of the heating body, poor thermal conductivity, etc., and reduce damage Hazardous, easy installation and removal, fast and uniform heat introduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

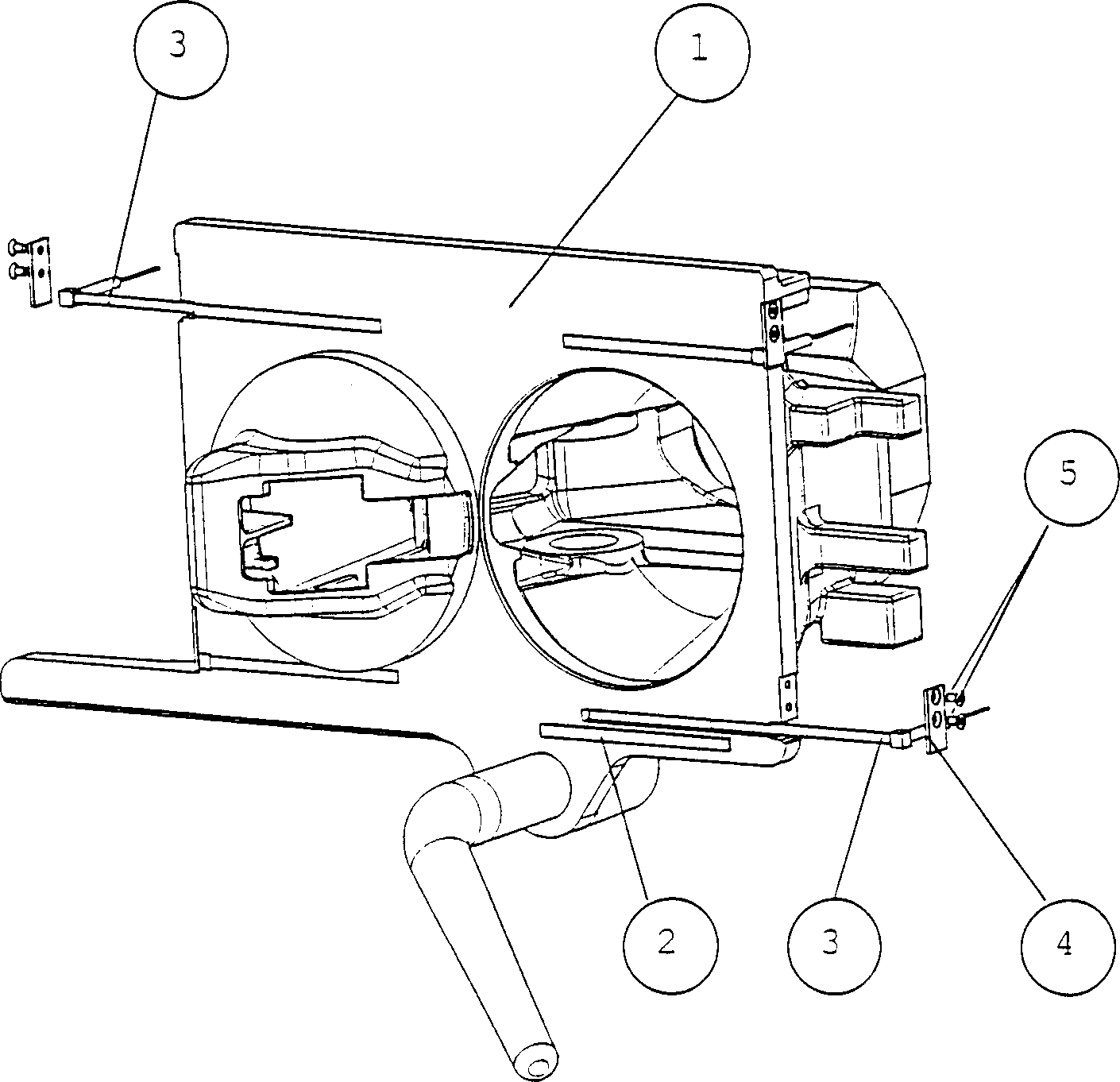

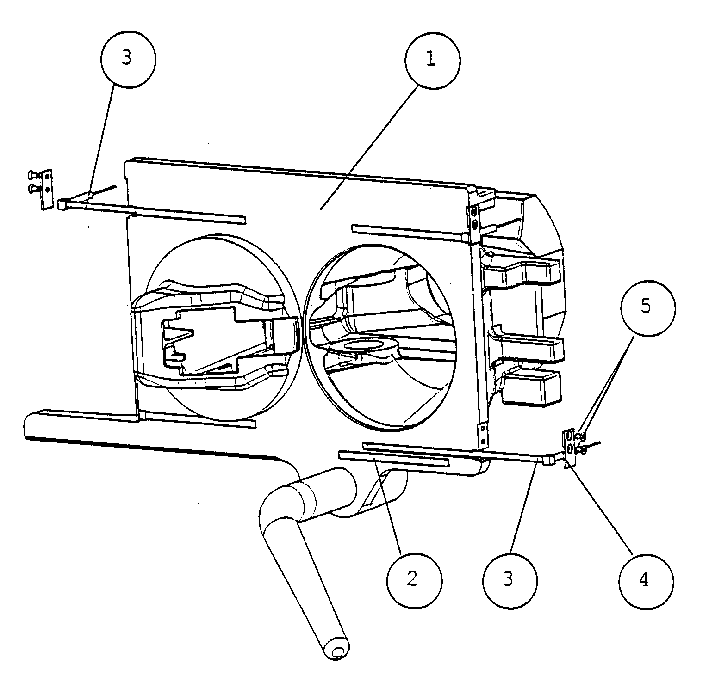

[0018] exist figure 1 The panel of the coupler head of the intermediate buffer coupler shown is provided with a recess as a groove structure. The grooves can be arranged in various orientations and spacings on the panel and can be closed with or by the panel strip 2 on the panel closing surface. The panel strips 2 are arranged in matching grooves and are preferably connected to the panel by brazing, the recess / groove formed in this way serves to receive the heating element 3 and their cross-sectional dimensions are precisely adapted to each other. After inserting each heating body 3 through the fixing plate 4, the heating body 3 can be fixed on the coupler head 1 by using the detachable fixing piece 5, and then the installation and disassembly can be realized. Importantly, it is also possible to embed the sensitive heating body after the panel strip 2 is arranged on the coupler body, thereby reducing the risk of damage to the heating body 3 used during the processing of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com