Seal structure used for high wet sensitive electronic device element and its producing method

An electronic device and highly moisture-sensitive technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as unexplained drying treatment methods, prevent premature damage to devices, enhance coordination, Enhanced moisture protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

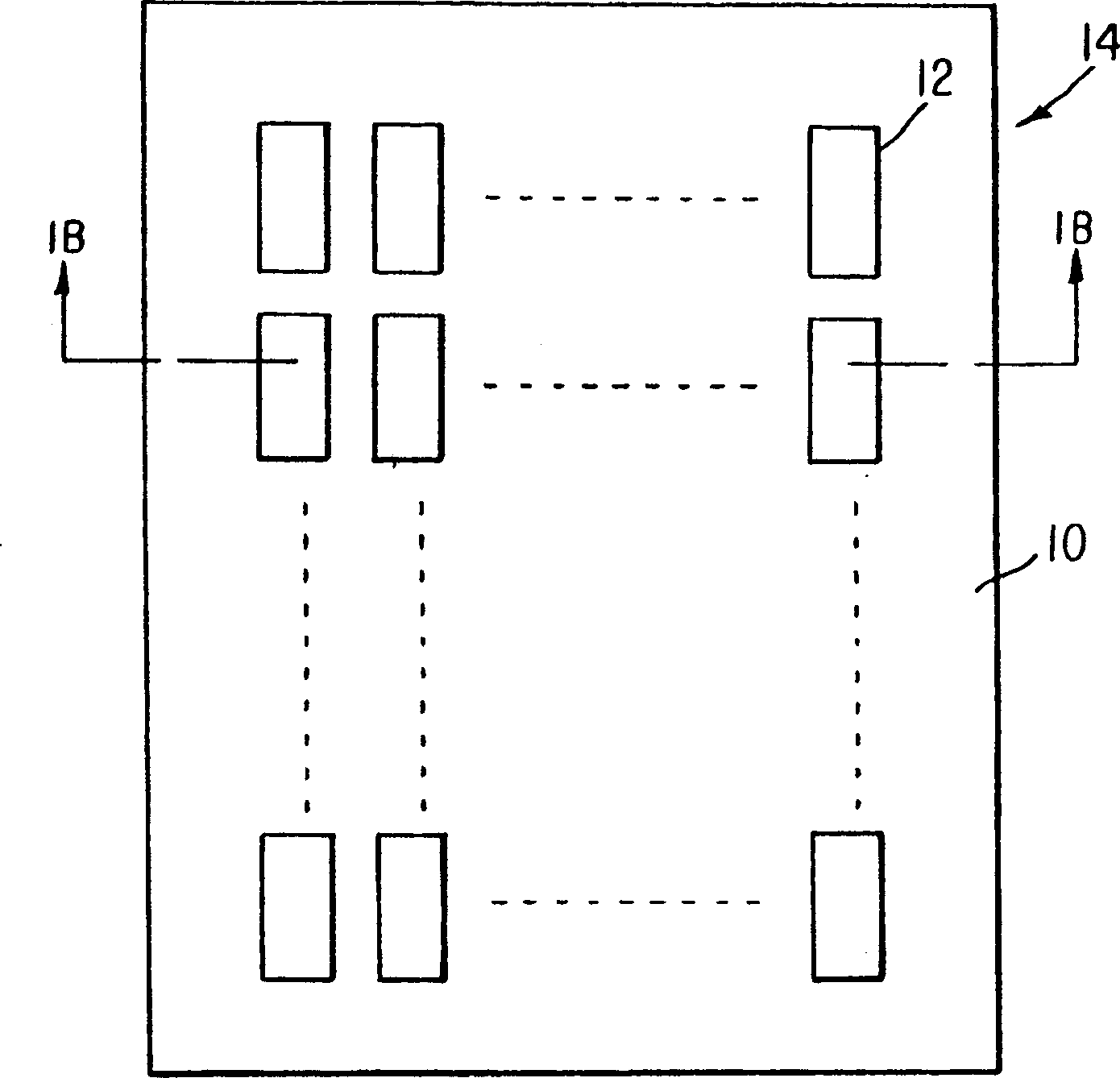

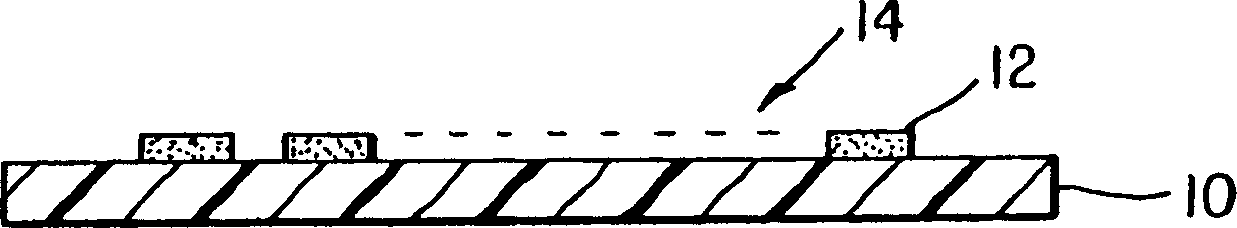

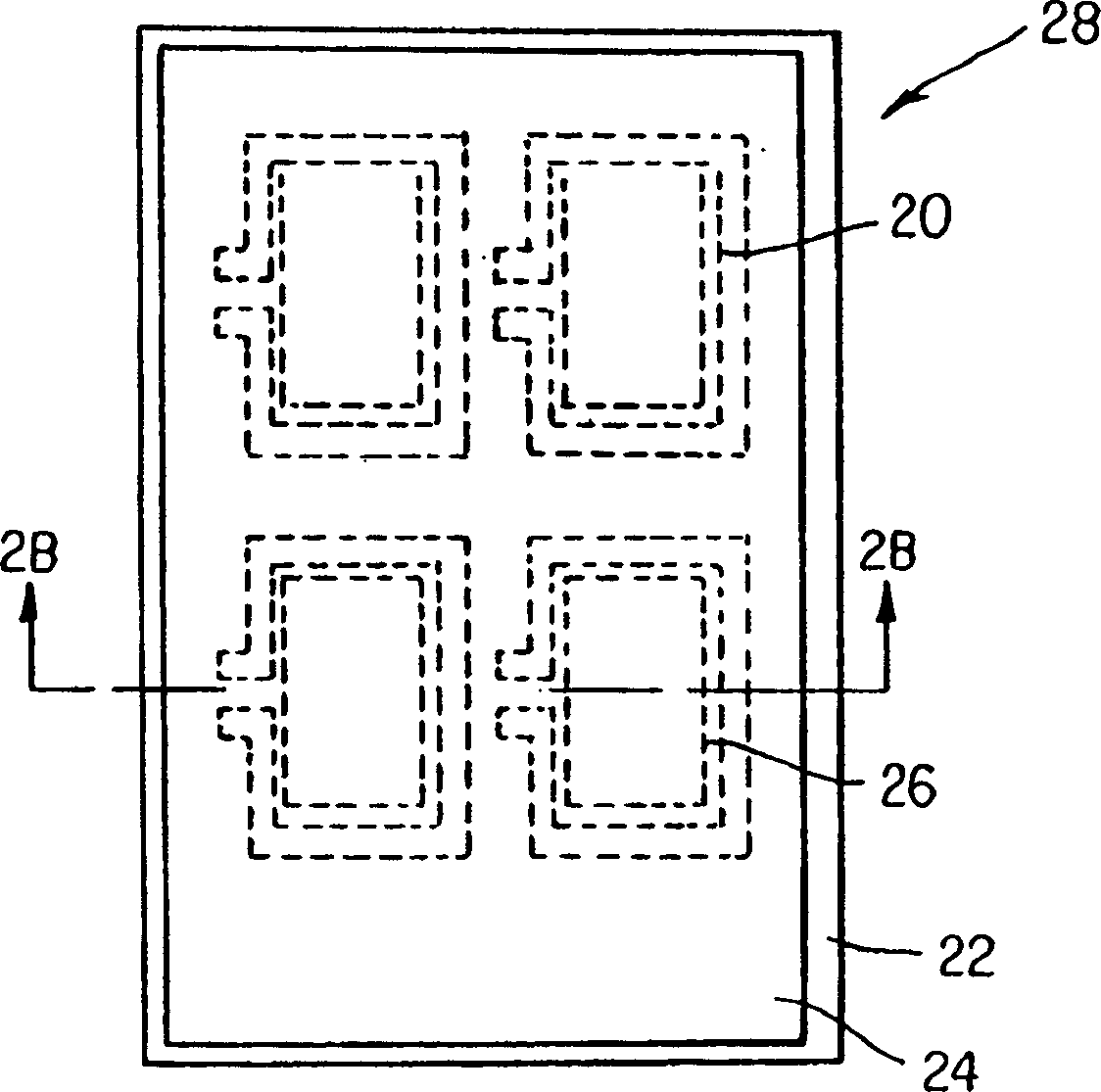

[0054] The term "highly moisture-sensitive electronic device component" means a component that includes one or more highly moisture-sensitive electronic devices during or after manufacture, or that includes one or more components of highly moisture-sensitive electronic devices. The term "highly moisture sensitive electronic device" refers to any electronic device that is susceptible to measurable degradation in device performance when ambient humidity levels are greater than 1000 ppm. The term "substrate" refers to an organic, inorganic, or combination of organic and inorganic solids on which one or more highly moisture-sensitive electronic devices are fabricated. The term "encapsulation" refers to an organic, inorganic, or combination of organic and inorganic solids used to protect one or more highly moisture-sensitive electronic devices from moisture by preventing or limiting moisture penetration. The term "encapsulant" refers to an organic, inorganic, or combination of org...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com