Film transistor array panel with visual checking device and its checking method

A thin-film transistor and panel technology, applied in the field of visual inspection, can solve problems such as difficult to obtain laser cutting space, difficult laser cutting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] A thin film transistor (TFT) will be described with reference to the drawings.

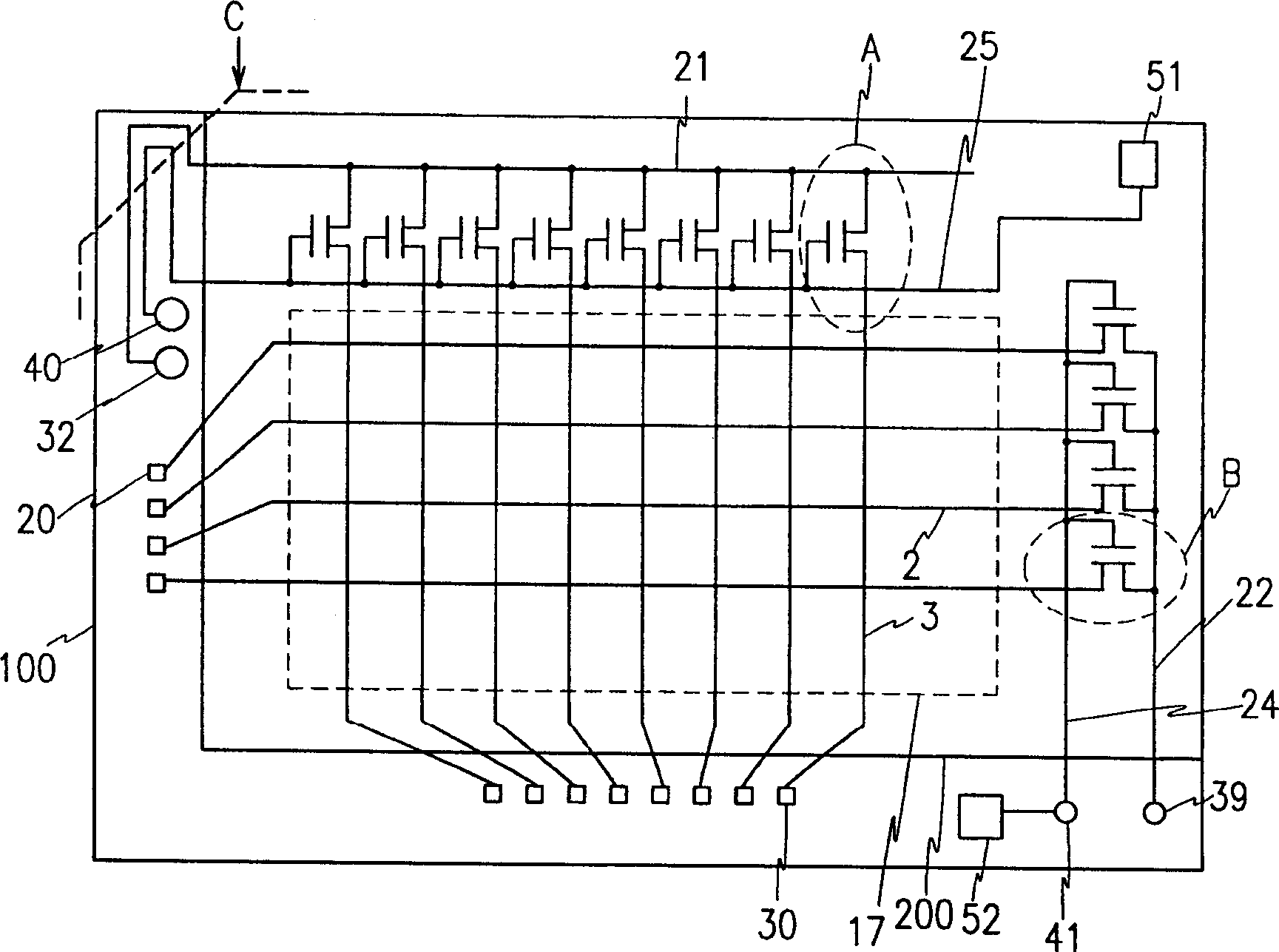

[0040] figure 1 are circuit diagrams according to the first and second embodiments of the present invention.

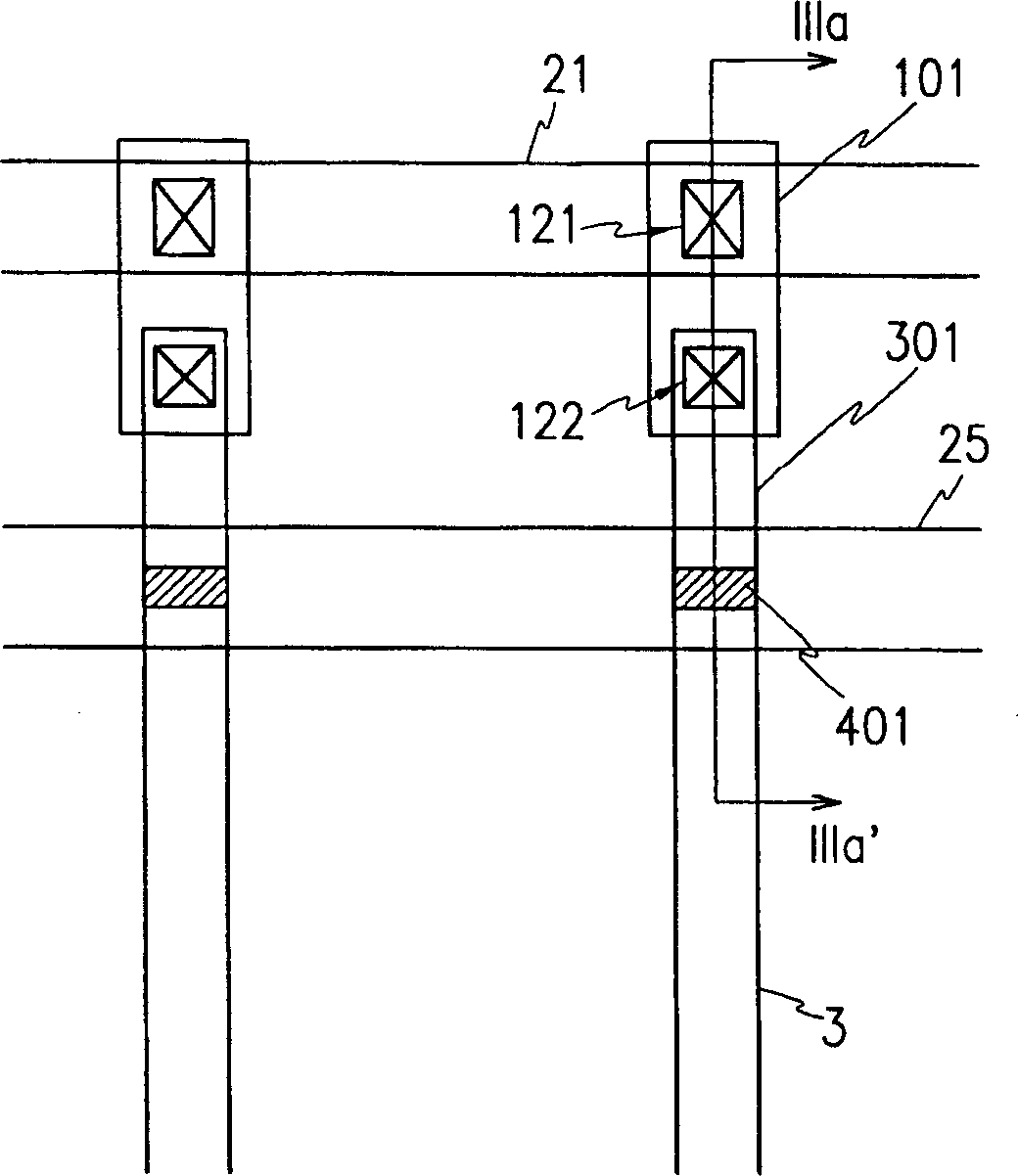

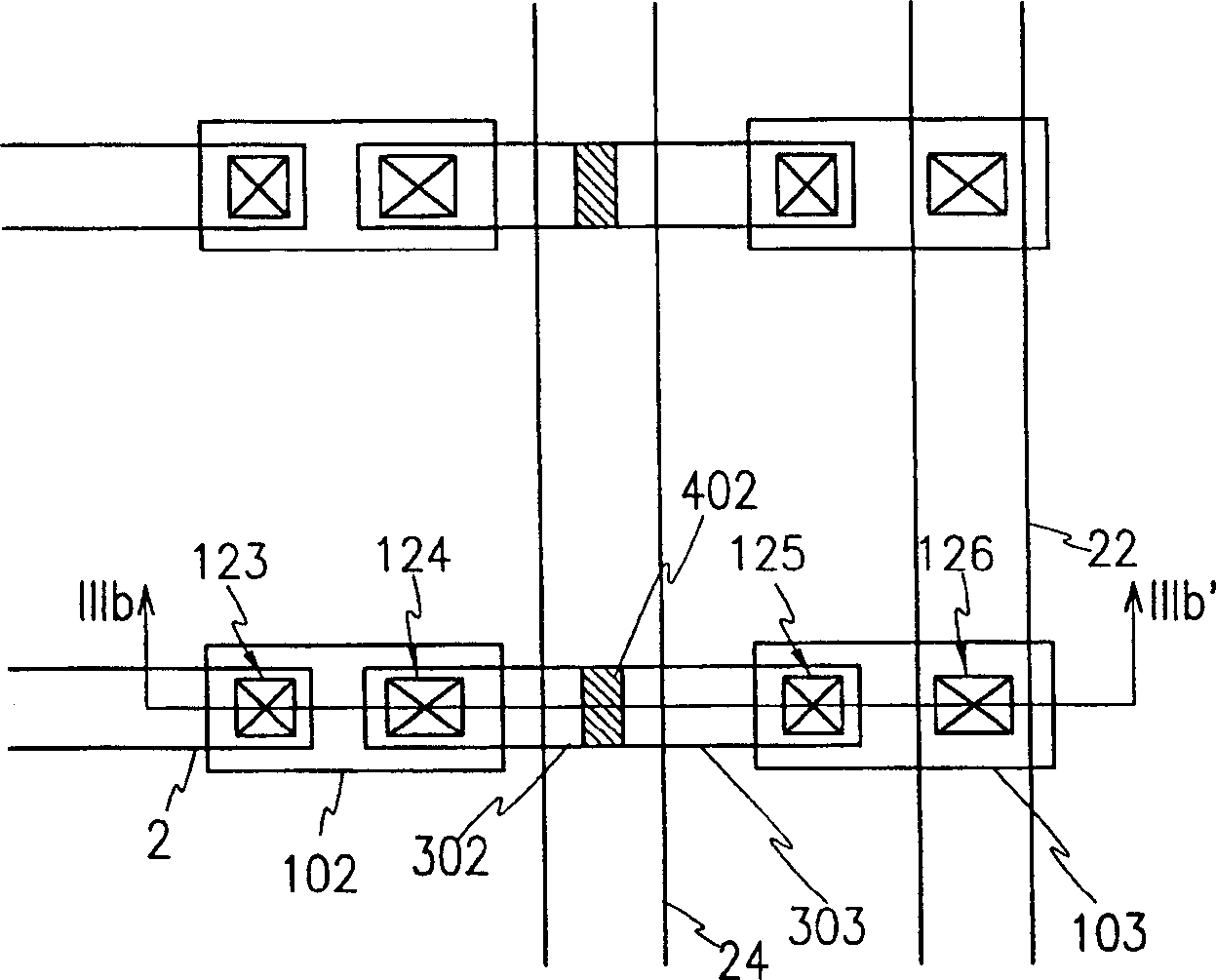

[0041] A plurality of gate lines 2 extend laterally, and a plurality of data lines 3 insulated to cross the gate lines 2 in a longitudinal direction are formed on an insulating substrate 100 . A plurality of gate pads 20 connected to the gate driver IC are connected to the first end of the gate line 2, and a plurality of data pads 30 connected to the data driver IC are connected to the second end of the data line 3 . The gate lines 2 and the data lines 3 cross each other to define pixel areas, and a group of pixel areas forms a display area. A portion other than the display area is defined as the surrounding area. A gate TFT B for inspection is connected to a third end opposite to the gate line 2 , and a data TFT A for inspection is connected to a fourth end opposite to the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com