Nanometer level ginseng product and its production process

A production method and nano-scale technology, which is applied in the production of nano-scale ginseng products, and in the field of nano-scale ginseng products, can solve the problems of not being able to dissociate active ingredients or nutritional ingredients of ginseng, affecting the absorption and transportation of active ingredients or nutritional ingredients, and wasting ingredients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

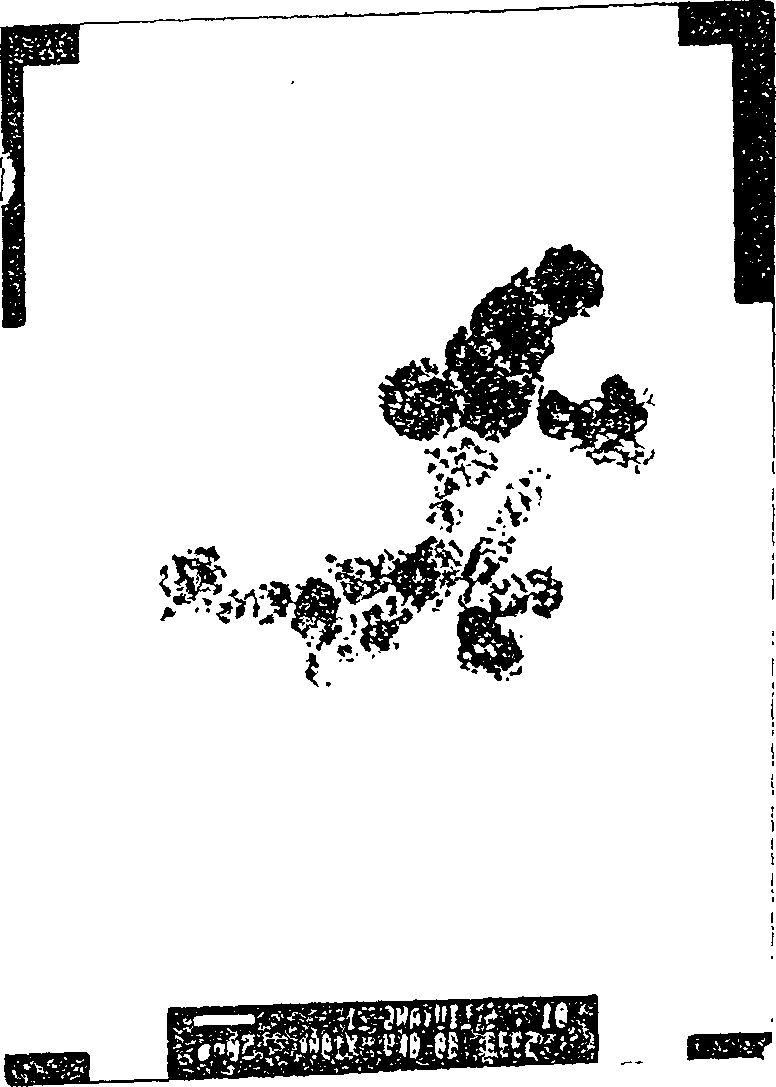

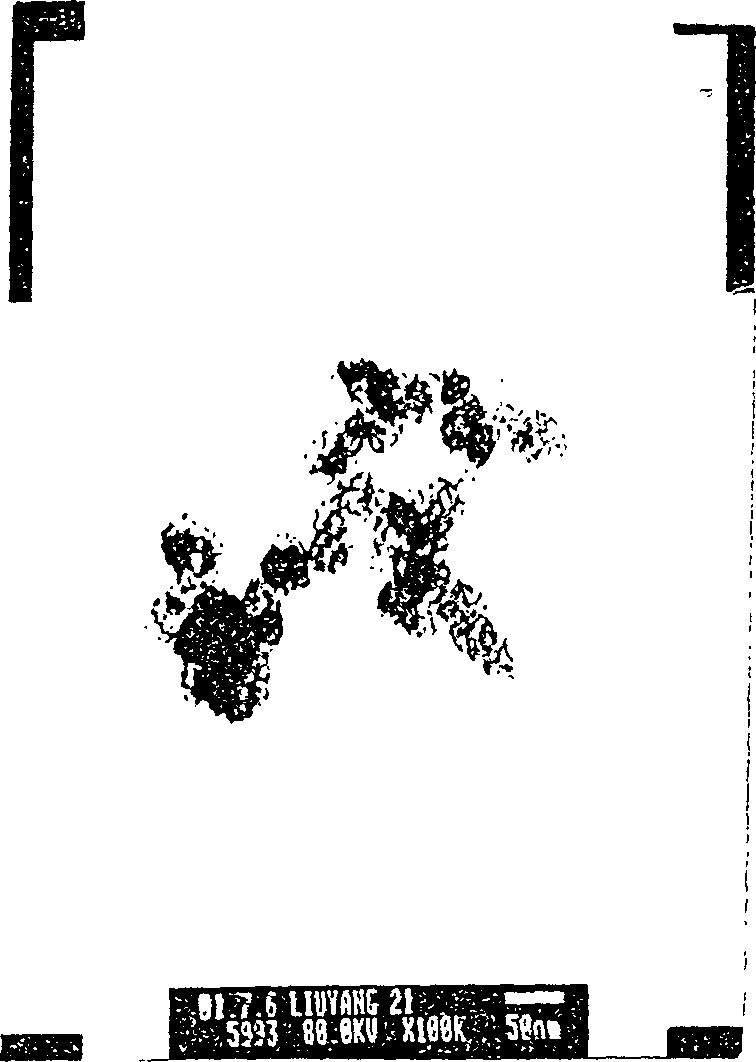

[0007] Example 1. Take 100Kg of ginseng, crush it to 80 mesh, add 8 times the amount of water to prepare a suspension, and then place it in an NZJ wet pulverizer to pulverize in the liquid to a particle size of 10-100nm to form a colloidal liquid.

Embodiment 2

[0008] Example 2. Take 100Kg of ginseng, crush it to 80 mesh, add 8 times the vegetable oil to prepare a suspension, and then place it in an NZJ wet pulverizer to pulverize in the liquid to a particle size of 10-100nm to form a colloidal liquid.

Embodiment 3

[0009] Example 3. Take 100Kg of ginseng, crush it to 80 mesh, add 8 times the animal oil to prepare a suspension, and then place it in an NZJ wet pulverizer to pulverize in the liquid to a particle size of 10-100nm to form a colloidal liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com