Modular stator structure

A technology of stator and iron core blocks, applied in the field of modular stator structure, can solve the problems of high cost, waste of resources, and unusable equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

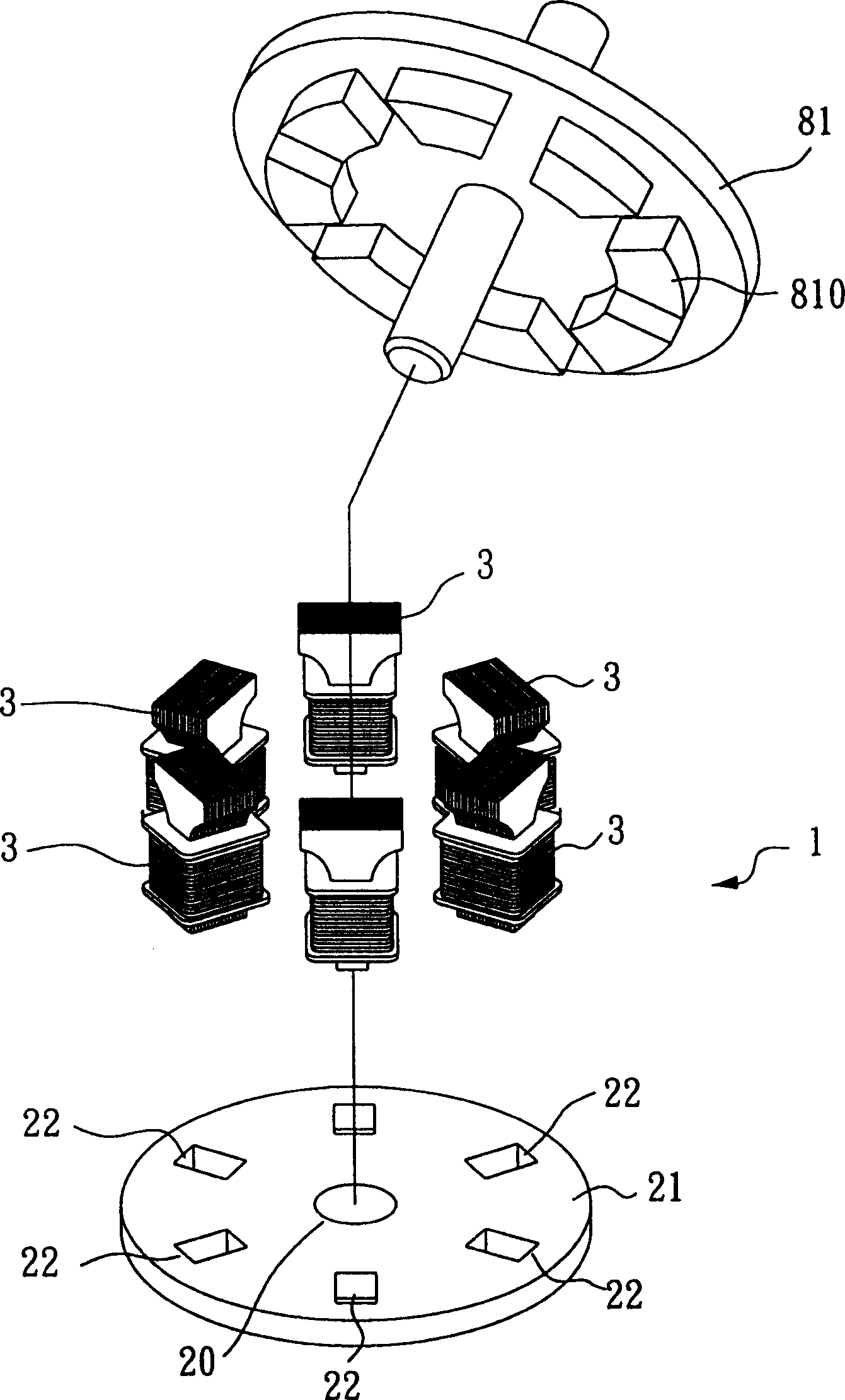

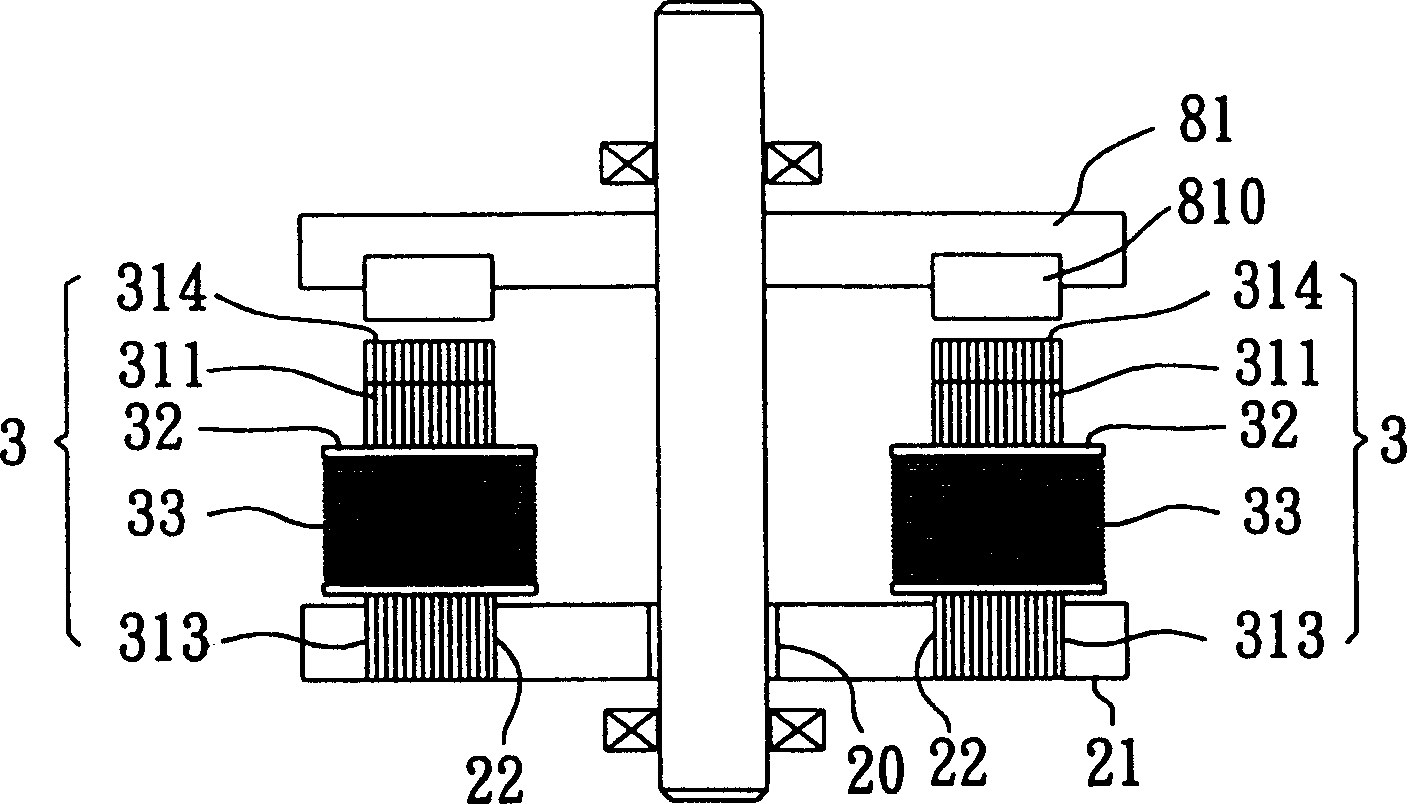

[0031] Regarding the first preferred embodiment of the modular stator structure of the present invention, the stator structure of an electric motor (motor) is used as an example to illustrate, please refer to figure 1 The three-dimensional exploded view shown is mainly composed of the base 21 and six core modules 3 .

[0032] The aforementioned base 21 is made of magnetically permeable materials such as iron and steel, and is in the shape of a disk. Six fixing grooves 22 are recessed on the surface of the base 21 along an annular interval. The six iron core modules 3 respectively correspond to the six fixing slots 22 assembled on the surface of the base 21 , and the base 21 can be matched with the rotor 81 to form a motor.

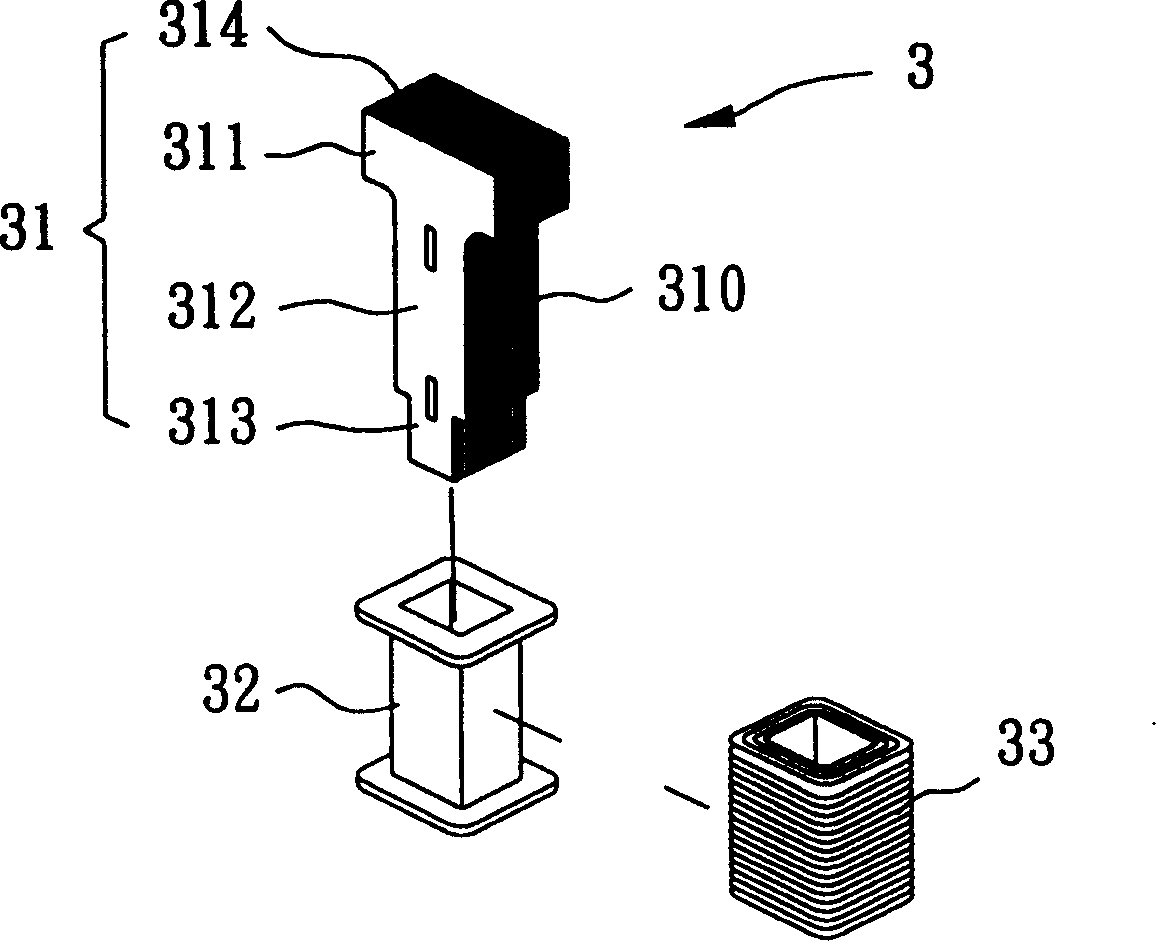

[0033] figure 2 It is a detailed exploded view showing the aforementioned iron core module 3 , and the iron core module 3 is composed of an iron core block 31 , an insulating bushing 32 , and a coil 33 . In this example, the iron core block 31 is formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com